8

The Deep Vacuum Method requires a vacuum pump

rated for 500 microns or less. This method is an eective

and ecient way of assuring the system is free of non-

condensable air and moisture. As an alternative, the Triple

Evacuation Method is detailed in the Service Manual for

this product model.

It is recommended to remove the Schrader Cores from the

service valves using a core-removal tool to expedite the

evacuation procedure.

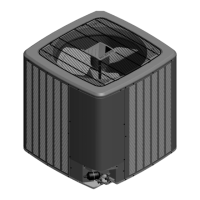

1. Connect the vacuum pump, micron gauge, and

vacuum rated hoses to both service valves.

Evacuation must use both service valves to eliminate

system mechanical seals.

2. Evacuate the system to less than 500 microns.

3. Isolate the pump from the system and hold vacuum

for 10 minutes (minimum). Typically, pressure will

rise slowly during this period. If the pressure rises

to less than 1000 microns and remains steady, the

system is considered leak-free; proceed to system

charging and startup.

4. If pressure rises above 1000 microns but holds

steady below 2000 microns, non-condensable air

or moisture may remain or a small leak is present.

Return to step 2: If the same result is achieved

check for leaks and repair. Repeat the evacuation

procedure.

5. If pressure rises above 2000 microns, a leak is

present. Check for leaks and repair. Repeat the

evacuation procedure.

5000

4500

4000

3500

3000

2500

2000

1500

1000

500

0 1 2 3 4 5 6 7 8 9

10

LEAK(S)

PRESENT

MINUTES

V

ACUUM

IN

MICRONS

CONDENSIBLES OR SMALL

LEAK PRESENT

NO LEAKS

NO CONDENSIBLES

GENERAL NOTES:

Adequate refrigerant charge for the matching indoor coil and

15 feet of line set is supplied with the heat pump unit. If liquid

line set exceeds 15 feet in length, refrigerant should be added

at 0.6 ounces per foot of liquid line.

NOTICE

ALL UNITS SHOULD HAVE A HIGH VOLTAGE POWER SUPPLY

CONNECTED 2 HOURS PRIOR TO STARTUP.

WARNING

REFRIGERANT UNDER PRESSURE!

• DO NOT OVERCHARGE SYSTEM WITH REFRIGERANT.

• DO NOT OPERATE UNIT IN A VACUUM OR AT NEGATIVE

PRESSURE. FAILURE TO FOLLOW PROPER PROCEDURES MAY

CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

CAUTION

OPERATING THE COMPRESSOR WITH THE SUCTION VALVE

CLOSED WILL CAUSE SERIOUS COMPRESSOR DAMAGE - SUCH

DAMAGE IS NOT COVERED BY OUR WARRANTIES.

CAUTION

USE REFRIGERANT CERTIFIED TO AHRI STANDARDS. USED RE-

FRIGERANT MAY CAUSE COMPRESSOR DAMAGE, AND IS NOT

COVERED BY THE WARRANTY. MOST PORTABLE MACHINES

CANNOT CLEAN USED REFRIGERANT TO MEET AHRI STAN-

DARDS.

Liquid and suction valves on heat pump unit are closed to

contain the charge within the unit. The unit is shipped with the

valve stems closed and caps installed.

CAUTION

PROLONGED OPERATION AT SUCTION PRESSURES LESS THAN

-

HEATING OF THE SCROLLS AND PERMANENT DAMAGE TO THE

SCROLL TIPS, DRIVE BEARINGS AND INTERNAL SEAL.

WARNING

HIGH VOLTAGE

DISCONNECT ALL POWER BEFORE SERVICING

OR INSTALLING THIS UNIT. MULTIPLE POWER

SOURCES MAY BE PRESENT. FAILURE TO DO SO

MAY CAUSE PROPERTY DAMAGE, PERSONAL

INJURY OR DEATH. DO NOT SERVICE THIS UNIT

WITHOUT FIRST INSURING THAT:

THE ELECTRICAL ACCESSORIES ARE INSTALLED ONLY IN

THE PRE-DRILLED MOUNTING HOLES.

THE ELECTRICAL WIRING IS NOT INSTALLED AND DOES NOT

HANG BELOW THE PRE-DRILLED MOUNTING HOLE OR LIE

IN THE UNIT BASE PAN.

NOTICE

VIOLATION OF EPA REGULATIONS MAY RESULT IN FINES OR

OTHER PENALTIES.

Loading...

Loading...