www.DaikinApplied.com 9 IOM 1207-6 • TRAILBLAZER

®

MODEL AGZ CHILLERS

CAUTION

All lifting locations must be used to prevent damage to unit.

DANGER

Improper rigging, lifting or moving of a unit can result in property

damage, severe personal injury or death. Follow rigging and moving

instructions carefully. Do not stand beneath the unit while it is being

lifted or installed.

Figure 1: Required Lifting Arrangement

Unit Placement

Trailblazer

®

units - both packaged units with pump packages

and condensing units for remote evaporator congurations -

are for outdoor applications and can be mounted either on a

roof or at ground level. For roof mounted applications, install

the unit on a steel channel or I-beam frame to support the unit

above the roof. For ground level applications, install the unit on

a substantial base that will not settle. Use a one-piece concrete

slab with footings extended below the frost line. Be sure the

foundation is level within 0.5” (13 mm) over its length and

width. The foundation must be strong enough to support the

unit weight - see Dimensional Drawings for Remote Evaporator

Units beginning on page 29 or see Dimensional Drawings

for Pump Package Units beginning on page 45.

Mounting Hole Access

The inside of the base rail is open to allow access for securing

mounting bolts, etc. Mounting location dimensions are given

in Dimensional Drawings beginning on page 29 for remote

evaporator units or page 45 for pump package units.

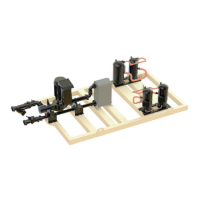

All compressor bolts, rubber grommets, and fasteners should

be left in place on the base plate as shown in Figure 2. None

of these fasteners are considered to be ‘temporary shipping

bolts.’

Figure 2: Compresssor Base Plate Mounting

Operational Spacing Requirements

Sucient clearance must be maintained between the unit

and adjacent walls or other units to allow the required unit air

ow to reach the coils. Failure to do so will result in a capacity

reduction and an increase in power consumption. No solid

obstructions are allowed above the unit at any height, see page

12 for details.

The clearance requirements shown are a general guideline

and cannot account for all scenarios. Such factors as prevailing

winds, additional equipment within the space, design outdoor

air temperature, and numerous other factors may require more

clearance than what is shown. Additional clearances may be

required under certain circumstances.

Graphs on the following pages give the minimum clearance for

dierent types of installations and also capacity reduction and

power increase if closer spacing is used. The graphs are based

on individual cases and should not be combined with other

scenarios.

CAUTION

Unit performance may be impacted if the operational

clearance is not sucient.

Service Clearance

The control panels are located on the end of the chiller and

require a minimum of four feet of clearance in front of the

panels. Compressors, lter-driers, and liquid line shuto valves

are accessible on each side or end of the unit. Do not block

access to the sides or ends of the unit with piping or conduit.

These areas must be open for service access. Minimum

service clearance is as follows:

Sides

• 4 Fan Models: Minimum of 4 feet (1.2 meters)

• 6 to 14 Fan Models: It is highly recommended to

provide a minimum of 8 feet (2.4 meters) on one side to

allow for coil replacement. Coils can be removed from

NOTE: Number of

fans and rigging

holes may vary

from this diagram.

The lifting method

will remain the

same.

Loading...

Loading...