5 Installation

Installation and operation manual

12

RXMLQ8 + RXYLQ10~14T7Y1B*

VRV IV system air conditioner

4P543426-1 – 2018.07

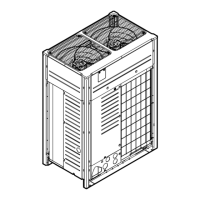

5.3.4 Multiple outdoor units: Knockout holes

Connection Description

Front connection Remove the front plate knockout holes to

connect.

Bottom connection Remove the knockout holes on the bottom

frame and route the piping under the bottom.

5.3.5 To protect against contamination

Seal the piping and wiring intake holes using sealing material (field

supply), otherwise the capacity of the unit will drop and small

animals may enter the machine.

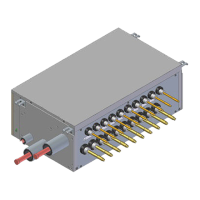

5.3.6 Using the stop valve and service port

To handle the stop valve

▪ Make sure to keep all stop valves open during operation.

▪ The stop valves are factory closed.

To open the stop valve

1 Remove the stop valve cover.

2 Insert a hexagon wrench into the stop valve and turn the stop

valve counterclockwise.

3 When the stop valve cannot be turned any further, stop turning.

4 Install the stop valve cover.

Result: The valve is now open.

To fully open the Ø19.1 mm~Ø25.4 mm stop valve, turn the

hexagonal wrench until a torque between 27 and 33 N•m is

achieved.

Inadequate torque may cause leakage of refrigerant and breakage of

the stop valve cap.

NOTICE

Pay attention that mentioned torque range is applicable for

opening Ø19.1~Ø25.4mm stop valves only.

To close the stop valve

1 Remove the stop valve cover.

2 Insert a hexagon wrench into the stop valve and turn the stop

valve clockwise.

3 When the stop valve cannot be turned any further, stop turning.

4 Install the stop valve cover.

Result: The valve is now closed.

To handle the stop valve cover

▪ The stop valve cover is sealed where indicated by the arrow. Do

NOT damage it.

▪ After handling the stop valve, tighten the stop valve cover

securely, and check for refrigerant leaks. For the tightening

torque, refer to the table below.

To handle the service port

▪ Always use a charge hose equipped with a valve depressor pin,

since the service port is a Schrader type valve.

▪ After handling the service port, make sure to tighten the service

port cover securely. For the tightening torque, refer to the table

below.

▪ Check for refrigerant leaks after tightening the service port cover.

Tightening torques

Stop valve

size (mm)

Tightening torque N•m (turn clockwise to close)

Shaft

Valve body Hexagonal

wrench

Cap (valve

lid)

Service

port

Ø9.5 5.4~6.6 4mm 13.5~16.5 11.5~13.9

Ø12.7 8.1~9.9 18.0~22.0

Ø15.9 13.5~16.5 6mm 23.0~27.0

Ø19.1 27.0~33.0 8mm 22.5~27.5

Ø25.4

Loading...

Loading...