© Danfoss | DCS (ADAP-KOOL®) | 2018.12

RI8SP202 | 8

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alternations can be made without subsequential changes being necessary in specifications already agreed.

All trademarks in this material are property of the respecitve companies. Danfoss and Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

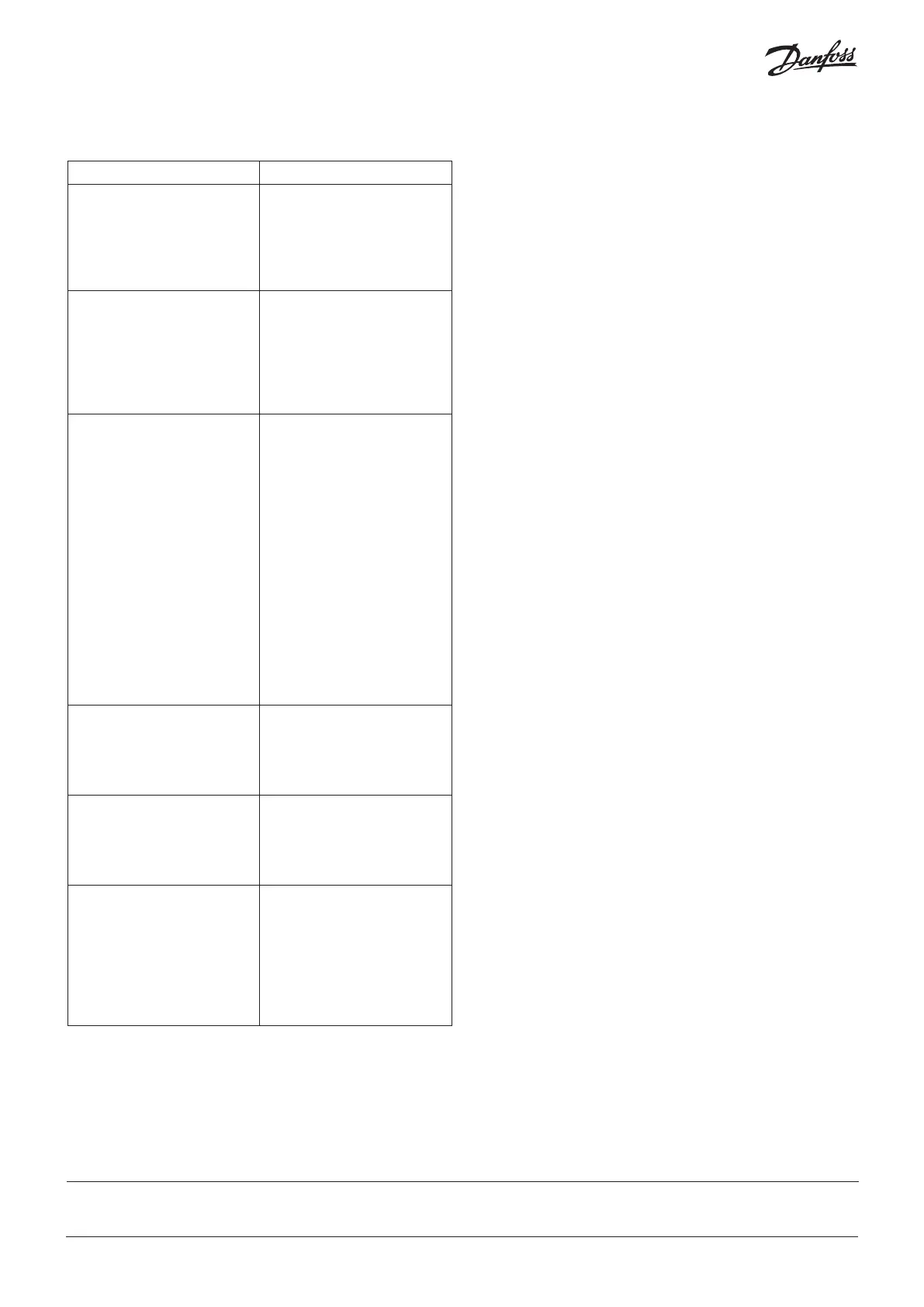

DGS - Troubleshooting

Symptom Possible Cause(s)

LED off • Check power supply. Check

wiring.

• DGS Modbus was possibly

damaged in transit. Check

by installing another DGS to

confirm the fault.

Green flashing The sensor calibration interval

has been exceeded or the

sensor has reached the end

of life.

Carry out calibration routine

or replace with a new factory

calibrated sensor.

Yellow • AO configured but not

connected (only 0-20 mA

output). Check wiring.

• Sensor type does not match

DGS specification. Check gas

type and measuring range.

• Sensor may be disconnected

from printed circuit board.

Check to see sensor is

properly connected.

• The sensor has been

damaged and needs to

be exchanged. Order

replacement sensor from

Danfoss.

• Supply voltage out of range.

Check power supply.

Yellow flashing • The DGS is set to service

mode from the hand held

service tool. Change setting

or await time out within 15

minutes.

Alarms in the absence of a leak • If you experience alarms in

the absence of a leak, try

setting an alarm delay.

• Perform a bump test to

ensure proper operation.

The zero-measurement drifts The DGS-SC sensor

technology is sensitive to the

environment (temperature,

moist, cleaning agents, gas'

from trucks, etc). All ppm

measurements below 75ppm

should be disregarded, i.e. no

zero-adjustment made.

Loading...

Loading...