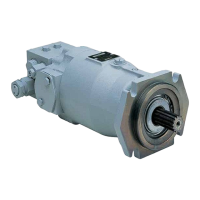

This document serves as a Service Manual and Repair Instructions for Danfoss Axial Piston Motors, Series 20. It provides comprehensive information for the normal maintenance and servicing of these hydrostatic units, including descriptions, troubleshooting, pressure setting, and repair procedures.

Function Description:

Danfoss axial piston fixed displacement motors, Series 20, are designed with a swash plate mechanism, making them suitable for hydrostatic transmissions with closed-loop circuits. The primary function of these motors is to convert hydraulic power into mechanical rotational energy. The output speed of the motor is directly proportional to the input flow it receives, while the output torque is proportional to the differential pressure applied across its main pressure ports. The direction of the motor's output shaft rotation is determined by the direction of the flow input to these main pressure ports. These motors feature a full-length shaft supported by a highly efficient tapered roller bearing arrangement, which provides a high loading capacity for external radial forces. The design also incorporates suitable shaft seals to achieve high case pressures without leakage, even at the lowest operating temperatures.

Important Technical Specifications:

The manual provides a model code breakdown that details various technical specifications.

- Series of Product: SMF (motor fixed association type 20).

- Displacement: Available in several displacements ranging from 33.3 cm³ [2.03 in³] to 333.7 cm³ [20.36 in³].

- Orientation of Rotation: Reversible.

- Input Port: Working port SAE-flange, available in 3000 psi SAE J518 (207 bar) for displacements 033-119 cm³ and 6000 psi SAE J518 (414 bar) for displacements 166-334 cm³.

- Shaft End: SAE-spline shaft 16/32, with varying teeth counts depending on displacement (e.g., 21 teeth for 033-070, 40 teeth for 334). Conic shaft end with toleranced key is also available upon request.

- End Cap Execution: Options include basic making (no entry), valve block with washing function (MS), additional shorting valve with connection plate (MR), and without valve block (AM 01000).

- High Pressure Relief Valve Settings: Typical numbers for possible levels of high pressure (pressure drop) in port A and/or B are provided, with characteristic numbers for settings ranging from 70 bar [1015 psi] to 385 bar [5580 psi], and up to 420 bar [6090 psi] for specific applications.

- Flushing Pressure: A typical flushing pressure of 12 bar [174 psi] is specified, with different settings available upon request.

- Operating Fluid: HLP fluid according to DIN 51524, ATF type A SUFFIX A, HD-SAE motor oils are recommended.

- Filtration Grade: 10 µm [394 µinch] nominal.

- Charge Pump Inlet Pressure: 0.85 bar [12.3 psi] absolute (-0.15 bar [-2.2 psi]) with a new filter element at approx. 50 °C [122 °F].

- Pressure Fluid Temperature Range: Min. -40 °C [-40 °F], Max. 95 °C [203 °F].

- Viscosity Range: Max. 1000 mm²/s [4630 SUS] (cSt) for short cold starts, Min. 7 mm²/s [49 SUS] (cSt). Recommended range: 12-60 mm²/s [66-278 SUS] (cSt).

- Installation Torque Values: Detailed torque values are provided for valve manifold assembly and end cap for various frame sizes (033, 052, 070, 089, 119, 166, 227, 334).

- Shaft End Play: Should be 0.08 to 0.18 mm [0.003 - 0.007 in] for frame sizes 033-089, and 0.15 to 0.3 mm [0.006 - 0.012 in] for frame sizes 119-334.

Usage Features:

The Danfoss Axial Piston Motors, Series 20, are designed for ease of use and integration into various mobile off-highway applications.

- Interchangeability: Many individual parts and assemblies, such as the servo valve, charge pumps, and manifold components, are interchangeable throughout the Series 20 family, simplifying maintenance and reducing spare parts inventory.

- On-Vehicle Maintenance: Many repairs and adjustments can be performed without removing the unit from the vehicle, provided it is easily accessible and can be thoroughly cleaned.

- Start-up Procedure: The manual outlines a detailed start-up procedure, emphasizing preconditions for trouble-free operation, including cleanliness, proper ventilation, correct operating fluid, oil level, and filtration. It also provides steps for first-time operation, including filling the pump and motor cases, venting the system, checking charge pressure, and performing a leak test.

- Troubleshooting Guides: Comprehensive flowcharts are provided to diagnose common issues such as transmission operating in one direction only, sluggish system response, system operating hot, or system not operating in either direction. These guides direct users to specific inspection and repair procedures.

Maintenance Features:

Maintenance is a critical aspect highlighted in the manual, with a strong emphasis on cleanliness and adherence to recommended procedures.

- Cleanliness: Contamination is identified as a primary cause of hydraulic unit breakdown. The manual stresses the importance of cleanliness during repairs, operation, oil changes, and filter changes.

- Oil Change Intervals: The first oil change is recommended after 80-100 hours or at least one year. Subsequent changes should occur after 500 hours or one year, and thereafter every 1000 hours or annually. Used fluid must be drained when the system is at operating temperature, and any residual dirt or sludge must be removed from the reservoir.

- Filter Replacement: The inlet filter element must be exchanged when pressure drops below 0.75 bar [10.9 psi] absolute or each time the pressure fluid is changed. The air filter should be cleaned whenever dirt accumulates.

- Leak Testing: Regular leak tests are recommended for the entire transmission system (inlet line, filter, pipes, hoses, valves, control elements, pump, and motor) to ensure environmental protection and reduce oil consumption. Leaking joints should be tightened when the system is not under pressure.

- Oil Level Checks: The oil level should be checked daily using the gauge glass, and any loss of oil rectified.

- Recommended Oils: The manual specifies HLP, ATF type A SUFFIX A, and HD-SAE motor oils, and warns against mixing different oils.

- Minor Repairs: The manual details procedures for minor repairs, such as changing the shaft seal, valve manifold assembly, and valve and bearing plate. It provides step-by-step instructions with illustrations for disassembly and assembly.

- Shaft Seal Replacement: Instructions are provided for both disassembly and assembly of the shaft seal, emphasizing careful handling of parts and replacement of O-rings.

- Valve Manifold Assembly Repair: Procedures for removing and replacing the valve manifold assembly, including the high-pressure relief valves and shuttle valve, are outlined. It is noted that the shuttle spool, valve cone, and manifold housing are matched and should not be replaced separately.

- Cylinder Block Kit, Swash Plate, and Motor Shaft Replacement: Detailed instructions are given for replacing these major components, including removal of bearings and checking shaft end play.

- Tools: A list of recommended tools for minor repairs, unit maintenance, and complete stripping of units is provided, including circlip pliers, screwdrivers, hammers, pliers, torque keys, spanners, Allen keys, bearing pullers, and depth gauges.

- Measurement Instruments: Specifications for pressure gauges (up to 60 bar, 600 bar, 8 bar) and vacuum gauges are listed for monitoring charge pressure, system pressure, inlet vacuum, and case pressure.