FCM 300 / FCD 300 / VLT

®

2800 / DP V1 PROFIBUS

■ Example

This example shows how PPO type 1 is used

for changing the ramp-up time (parameter 207)

to 10 seconds and for commanding a start

and speed reference of 50%.

Frequency conve rter parameter settings:

P502: serial port

P512: Fieldbus profile (Profidrive profile)

PPO. Parameter-Process Data Object

PCD: Process Data

PCV: Parameter-Characteristics-Value

PCA: Parameter-Characteristics (Bytes 1, 2)

PCA handling below

IND: Subind ex (Byte 3), ( Byte 4 is no t used)

PVA: Parameter value (Bytes 5 to 8)

CTW: Control word see section Control word

STW: Status word see section Status word

MRV: Main reference value

MAV: Main actual value

PCV

PCA - Parameters Characteristics

15 14 13 12 11 109876543210

RC SMP PNU

RC: Request /respons Characteristics (Range 0..15)

SPM: Toggle-Bit for Spontaneous Messages

PNU: Parameter # (Range 1..1999)

PCA part (byte 1-2) The RC part tells what the PCV

part must be used for. The functions available appear

from the table, see section PCA handling.

When a parameter is to be c hanged, choose value 2

or 3, in this example 3 is chosen, because parameter

207 covers a long word (32 bits).

SPM bit:

The function is explained in section Spontane ous

messages, in the example the function Spontaneous

Messages is not applied (parameter 917 = OFF),

therefore SPM is set for 0. PNU = Parameter number:

Parameter number is set for: 207 = C F Hex. This

means that the value of the PCA part is 30CF Hex.

IND (bytes 3-4):

Used when reading/changing parameters with

subindex, for example parameter 915. In the example

bytes 3 a nd 4 are set to 00 Hex.

PVA (bytes 5-8):

The data value of parameter 207 must be changed

to 10.00 seconds. The value transmitted must be

1000, because the conversion index for parameter

207 is -2, this m ea ns that the value received by

the frequency converter is divided by 100, making

the frequency converter perceive 1000 as 10.00.

Bytes 5-8 = 1000 = 03E8 He x.

PCD

CTW according to Profidrive profile:

Control words consisting of 16 bi

ts, the meaning of

the various bits appears from the table, see section

Control word/Status word. The following bit p attern

sets all necessary start com

mands:

0000 0100 0111 1111 = 047F Hex.*

0000 0100 0111 1110 = 047E Hex.*

0000 0100 0111 1111 = 047F Hex

.

Quickstop: 0000 0100 0110 1111 = 046F Hex.

Stop: 0000 0100 0011 1111 = 043F Hex.

* For restart after power up: Tr

ip OFF 2 and 3.

MRV:

Speed reference, the data format is "Standardized

value". 0 Hex = 0% and 4000 Hex = 100%.

In the example 2000 Hex is use d corresponding to

50% of maximum frequency

(parameter 202).

The whole PPO therefore

gets the following value in Hex:

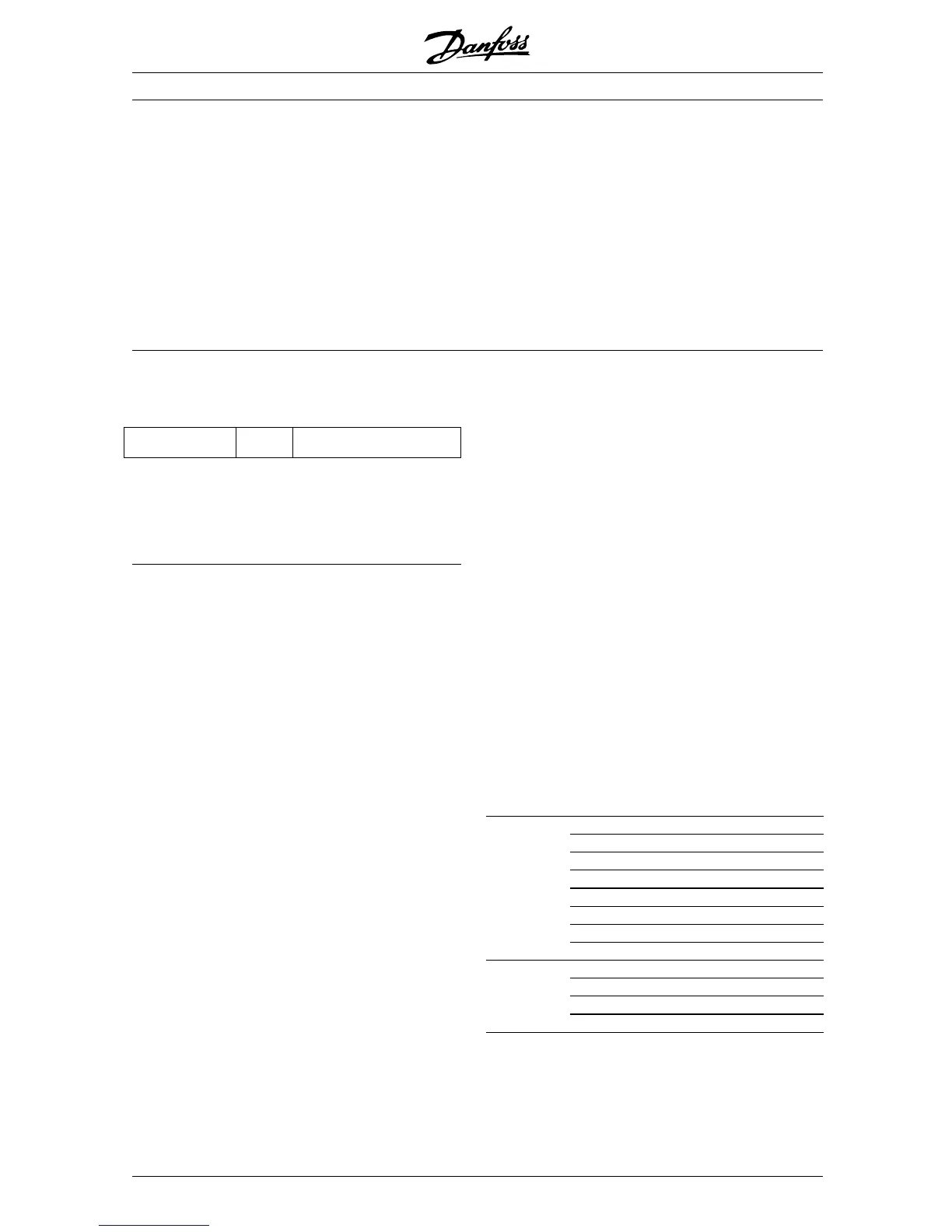

Byte Value

PCA 1 30

PCA 2 CF

IND 3 00

IND 4 00

PVA 5 00

PVA 6 00

PVA 7 03

PCV

PVA 8 E8

CTW 9 04

CTW 10 7F

MRV 11 20

PCD

MRV 12 00

The Process data within the PC D part is acting on the

frequency converter imme diately, and can be updated

from the master as quickly as possible.

MG.90.A5.02 - VLT is a registered Danfoss t rademark

28

Loading...

Loading...