FCM 300 / FCD 300 / VLT

®

2800 / DP V1 PROFIBUS

Read only parameters, as for example data read

out parameters, will not be registered as modified

eventhough they are changing.

When a 0 is returned as parameter number the list ends.

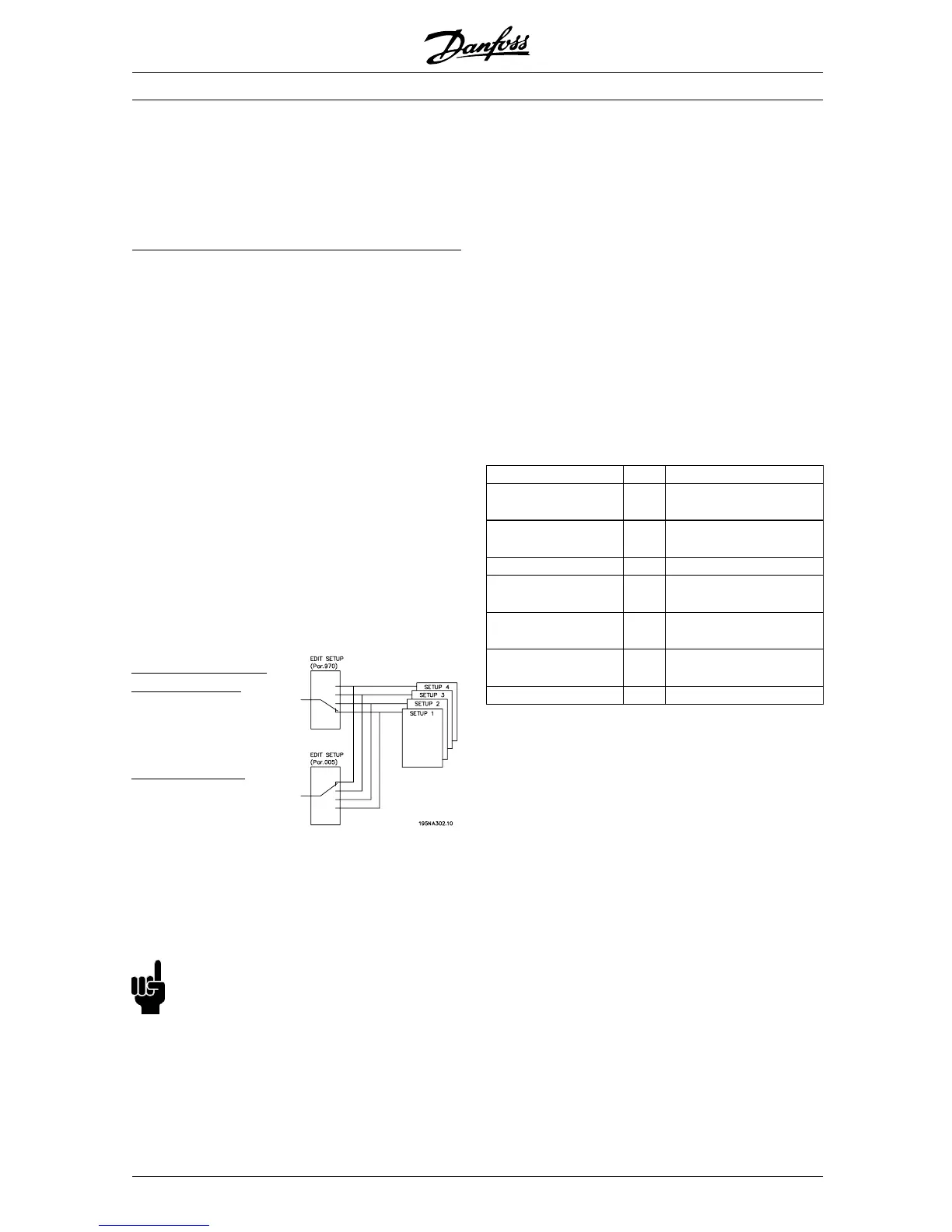

■ Read/write on frequency converter parameters

In an automation system, frequency converter

parameters can be accessed either from the Process

controller (i.e. PLC), or by various kinds of HMI

equipment. In order not to interfere access from

controllers and tools, the following should be taken

into consideration: Parameter acc ess in the drive is

performed in two logical parameter channels, which

can be individally programmed to access a certain

parameter setup via parameters 005 Programming

Setup and 970 Parameter setup selection. This

means, that before writing or reading to a parameter

in a certain frequency converter set-up from a PLC,

the parameter 970 must bne set to the desired

set-up. For acces s from HMI equipment, the access

is controlled by parameter 005. The figure below

shows this behaviour, and the possible sources of

the two logical parameter channels.

VLT frequency converter

A

ccess from process

control e.g. PLC:

- PCV channel (DP Vo)

-MSAC Master Class 1

A

ccess from HMI:

- Local Co ntrol Panel

- FC standard interface

- MSAC Master class 2

Please note, that even though these two logic al

parameter channels are separated, data conflict can

occour, if w rite on parameters is made from a HMI unit

into a set-up which is actively used by the frequency

converterorusedbytheprocesscontroller(e.g. PLC).

NB!:

For backward compability reasons the following

behaviour must be observed:

A Read or Write on parameter 970 via the MSAC

master class 2 connection will be accepted, but the

value will internally be read /written to parameter 005.

A Read or Write on parameter 005 via the process

controller channel will be ac cepted, but the value will

internally be read/written to parameter 970.

For parameter store, the following should be observed:

A Write command to a frequency converter parameter

via the MSAC Master class 2 co nnection will

be stored in RAM and in Non Volatile Memory.

Please note, that continuous writing to frequency

converter parameters via the MSAC Master class

2 connection s hould be avoided in order not to

damage the Non Volatile Memory.

A Write command to a frequency converter parameter

via the Process Control channel will be stored in RAM

only. Store in Non Volatile Mem ory is possible by writing

a store command to parameter 971 Save data values,

which w ill result in store of the entire set-up in NVRAM.

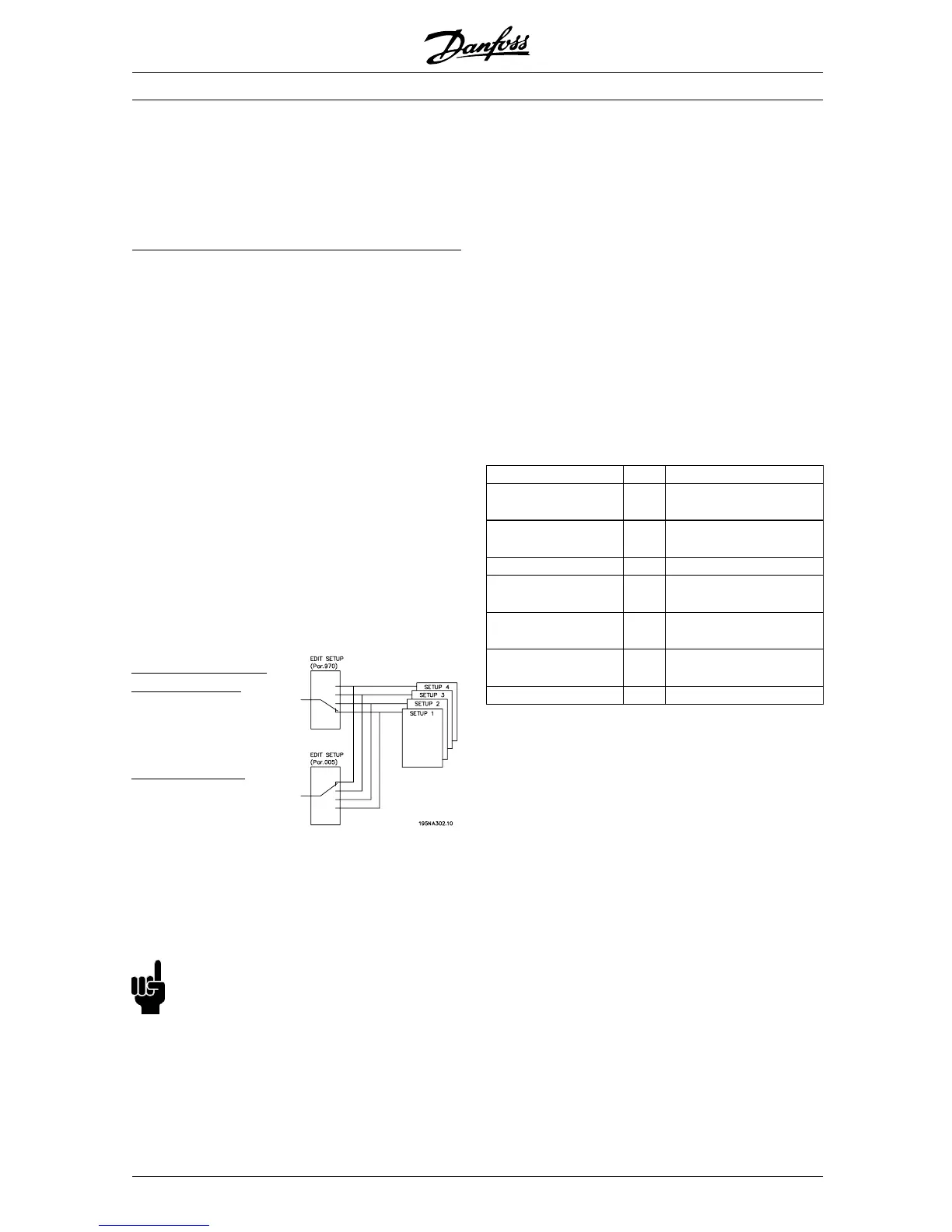

The table below shows how data write from various

sources are stored in the frequency converter:

Data source RAM NVRAM

PCV channel (DP V0) Yes Store set-up by parameter

971

MSAC Master Class 1 Yes Store set-up by parameter

971

Local Control Panel Yes Yes

MCT 10 software via FC

interface

Yes Yes

MCT10softwarevia

MSAC 2

Yes Yes

FC standard interface Yes Yes, by specific Write

command

MSAC Master Class 2 Yes Yes

MG.90.A5.02 - VLT is a registered Danfoss t rademark

38

Loading...

Loading...