VLT® 2800 Series

■ Tightening torques, control cables

Control wires must be connected with a tightening

torque of 0.22–0.25 Nm.

■ Electrical installation, control terminals

NOTE

Using unshielded/unarmored cable may not

comply with some EMC/RFI requirements.

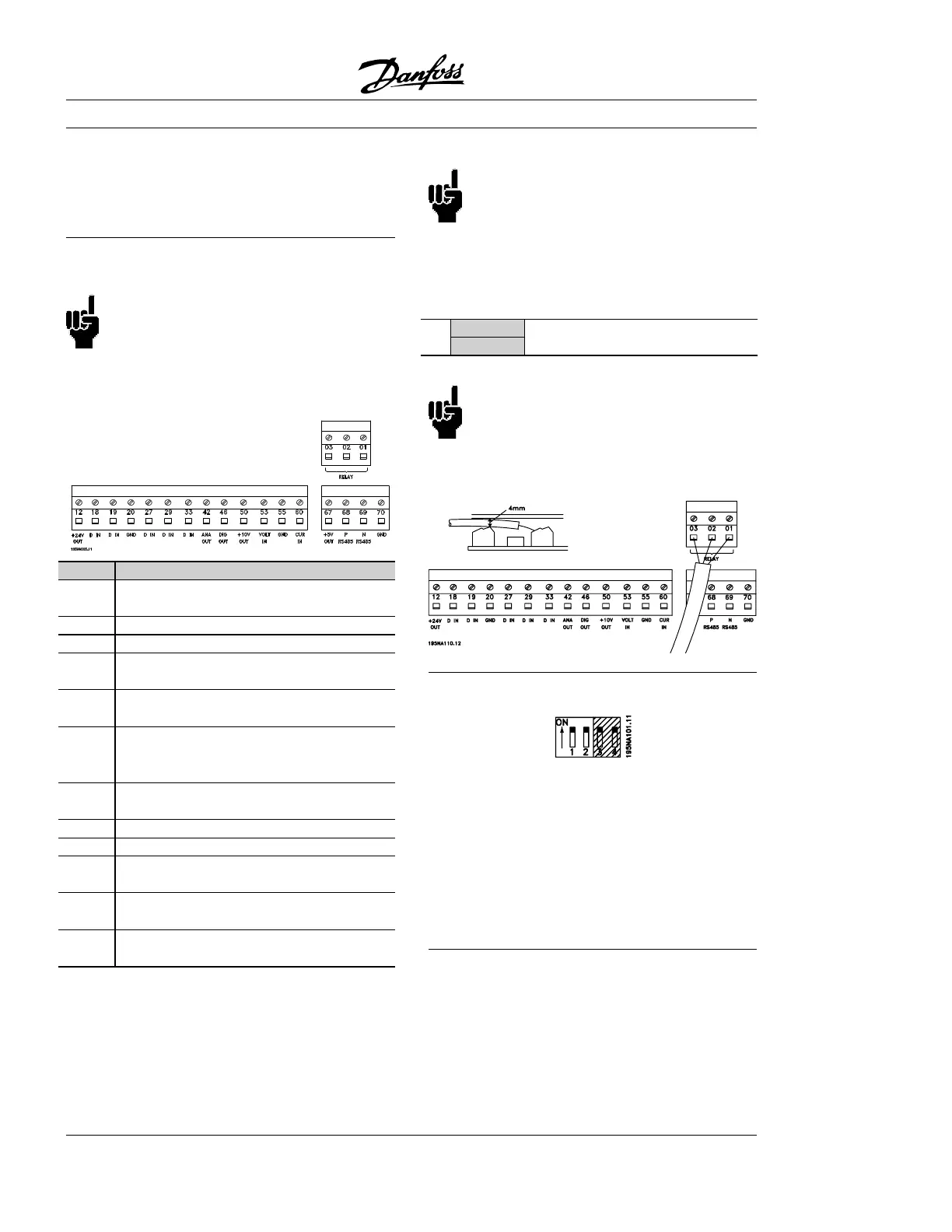

Refer to the following table for VLT 2800 terminal

designations and their functional descriptions.

No. Function

01-03 Relay outputs 01-03 can be used for

indicating status and alarms/warnings.

12 24 VDC voltage supply.

18-33 Digital inputs.

20, 55 Common frame for input

and output terminals.

42 Analog output for displaying frequency,

reference, current or torque.

46

1

Digital output for displaying status,

warnings or alarms, as well as

frequency output.

50 +10 VDC supply

voltage for potentiometer or thermistor.

53 Analog voltage input 0 - 10 V DC.

60 Analog current input 0/4 - 20 mA.

67

1

+ 5 VDC supply voltage

to Profibus.

68,

69

1

RS-485, Serial communication.

70

1

Frame for terminals 67, 68 and 69.

Normally this terminal is not to be used.

1. The terminals are not valid for DeviceNet. See the

DeviceNet manual, MG.90.BX.YY for further details.

NOTE

To supply internal 24 VDC voltage to the

digital input terminals, jumper terminal

12 to terminal 27.

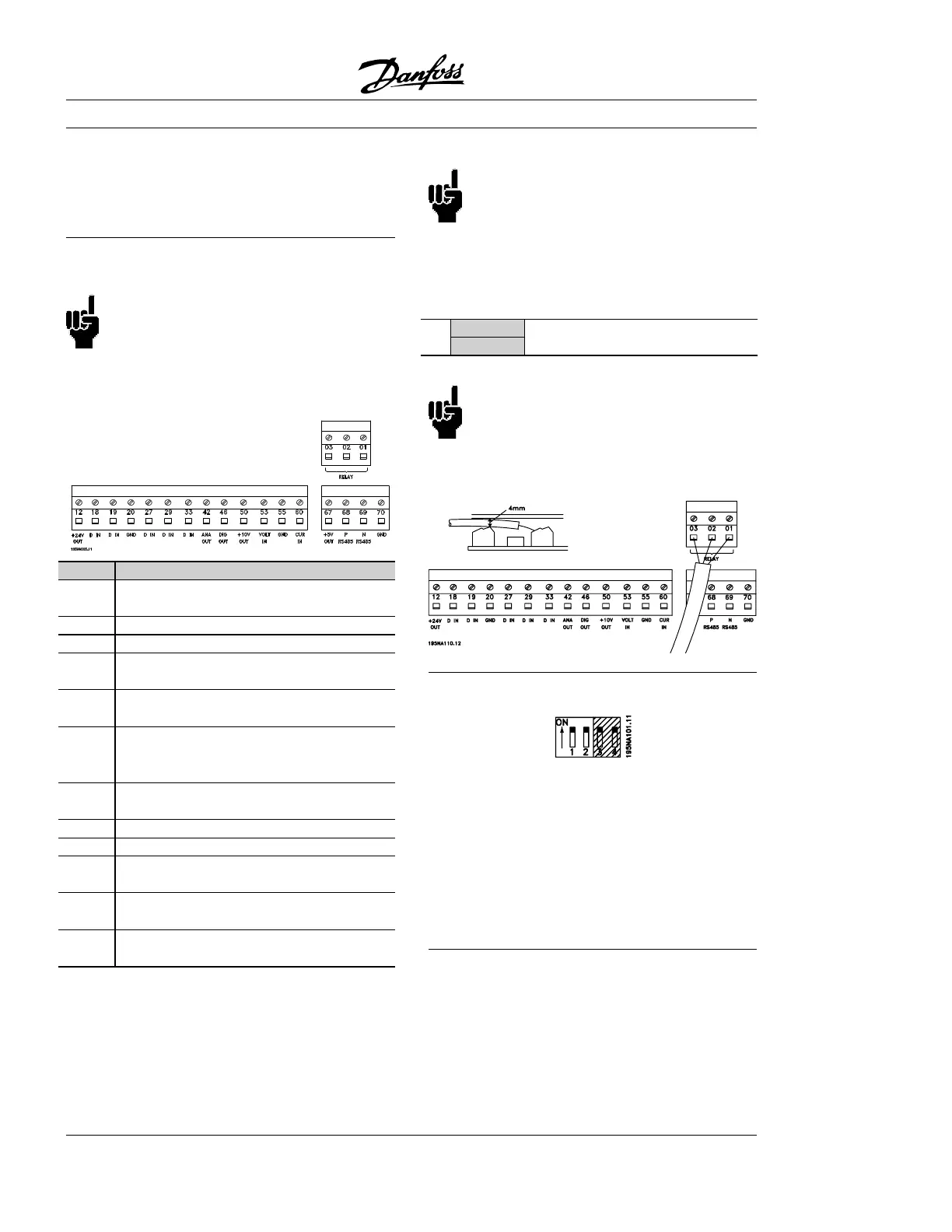

■ Relay connection

See parameter 323, Relay output for programming

of relay output.

No. 01 - 02 1 - 2 make (normally open)

01 - 03 1 - 3 break (normally closed)

NOTE

The cable jacket for the relay must cover

the first row of control card terminals -

otherwise the galvanic isolation (PELV)

cannot be maintained. Maximum cable diameter:

0-160 in (4 mm). See drawing.

■ Profibus DIP switches setting

The dip switch is only on the control card with Profibus

DP communication. The switch position shown is the

factory setting. Switches 1 and 2 are used as cable

termination for the RS-485 interface. If the adjustable

frequency drive is located as the first or last (or only)

unit in the bus system, switches 1 and 2 must be ON.

On the remaining adjustable frequency drives, switches

1 and 2 must be OFF. Switches 3 and 4 are not applied.

MG.28.A8.22 - VLT is a registered Danfoss trademark

20

Loading...

Loading...