24

5.5.2. High Pressure Cutout Switch

Each refrigerant circuit is protected by a high head pressure cutout switch with a manual reset button.

The cutout pressure rating for refrigerant R-407C is 400 psi. Physical location is near the compressor

which may be either in the evaporator or the condensing section.

5.5.3. Low Pressure Cutout Switch

Each circuit also contains a low suction pressure cutout switch with automatic reset. The cutout

pressure rating for this switch is 30 psi. Physical location is near the compressor which can be either

in the evaporator or the condensing section.

6.0 GLYCOL SYSTEMS

6.1 Glycol Concentration

The system must be fi lled with water and the appropriate amount of ethylene or propylene glycol to

protect against winter freeze-up. To achieve the approximate glycol concentration, it is necessary

to know the total system volume. This consists of the sum of the fl uid cooler volume, the evaporator

unit volume, and the volume of the interconnecting piping.

The following tables can be used for arriving at an approximate system volume. After installation,

the glycol percentage should be checked. The glycol percentage should also be checked at regular

intervals to ensure freeze protection.

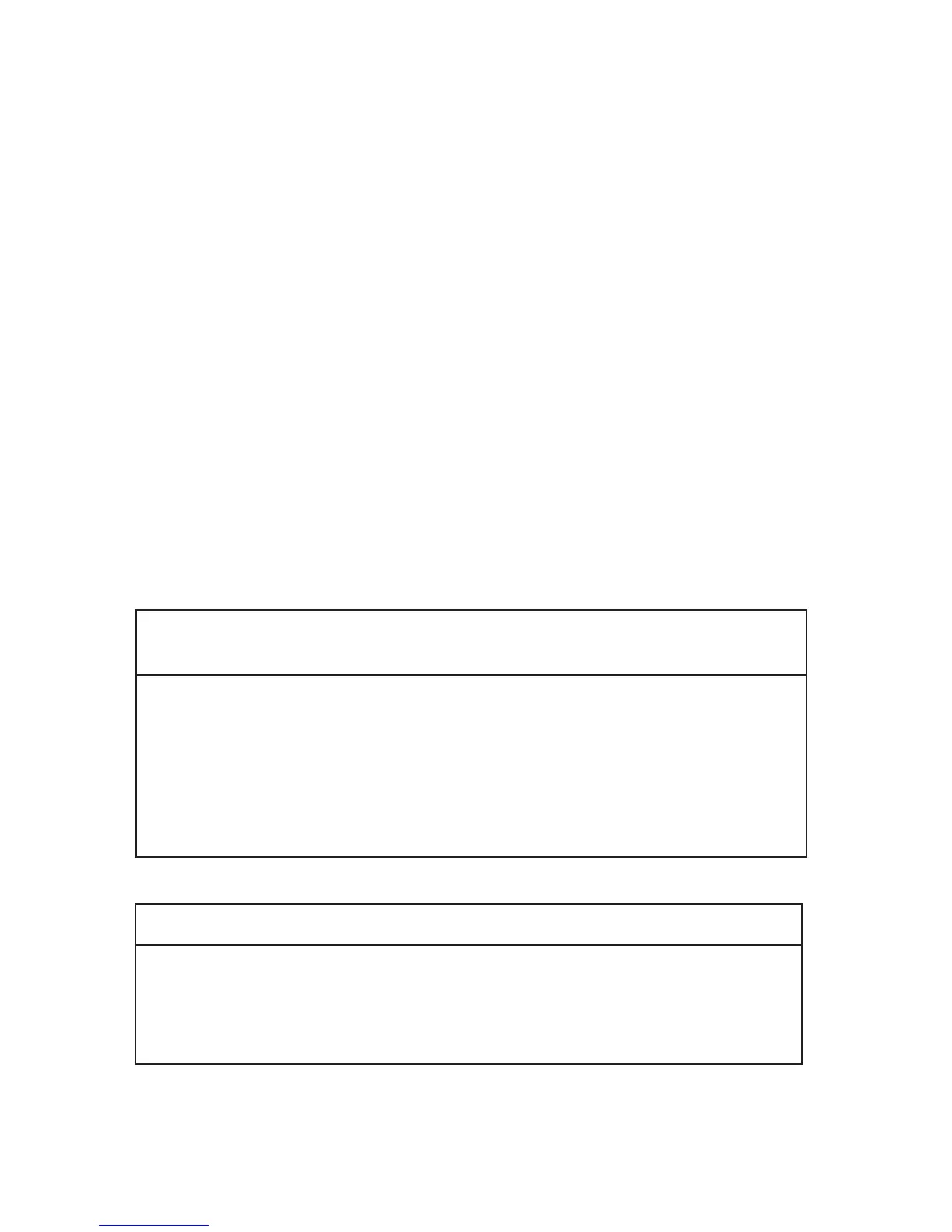

6.2 Internal (Fluid) Volume

Evaporator Without With

Internal Volume Energy Saver Coil Energy Saver Coil*

Model Volume, Gallons Volume, Gallons

DALG 06, single circuit 3.0 11.5

DALG 08, single circuit 3.0 11.5

DALG 10, single circuit 4.0 10.5

DALG 13, single circuit 4.0 10.5

DALG 06, dual circuit 4.0 12.5

DALG 08, dual circuit 4.0 12.5

DALG 10, dual circuit 5.0 11.5

DALG 13, dual circuit 5.0 11.5

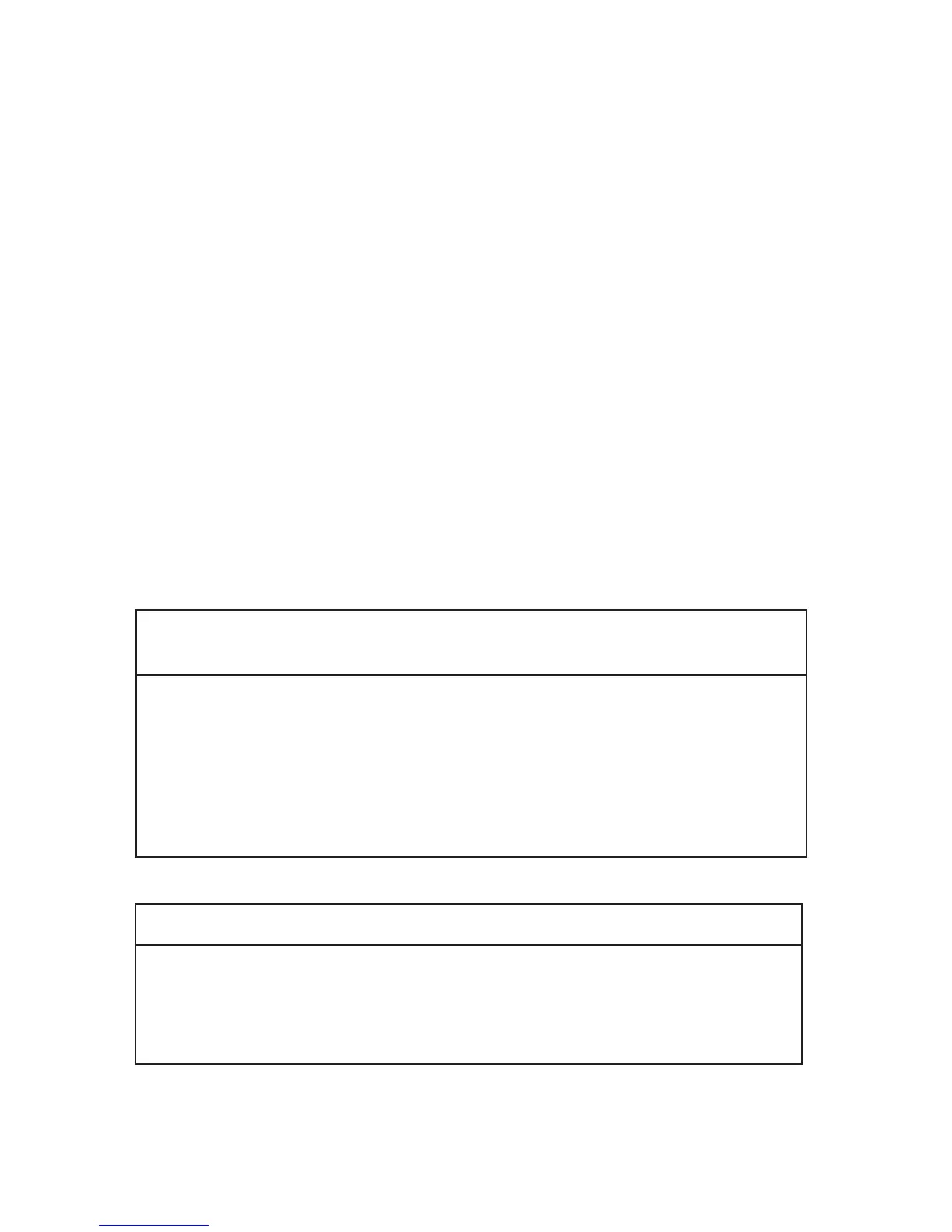

6.3 Fluid Cooler Internal Volume

Fluid Cooler Internal Fluid Cooler Internal

Model Volume, Gallons Model Volume, Gallons

DAFC 06 2.5 DAFC 17 6.6

DAFC 07 3.4 DAFC 21 7.4

DAFC 09 4.2 DAFC 24 9.8

DAFC 11 3.3 DAFC 28 12.3

DAFC 15 4.9 DAFC 30 9.8

* 6 and 8 ton units use a 4 row energy save coil

10 and 13 ton units use a 3 row energy saver coil.

Loading...

Loading...