IP55 Compliant Connection

Forsomeinstallations,suchaswetareasindairies,thepumpisrequiredtobe

IPX5compliant.TheDynaoHSpumpisIP55compliant.

Pipe Connections

For best performance use P.V.C. or

polythene pipe at least the same

diameter as the pump’s inlet. Larger

diameter pipe may be used to minimise

resistancetoowwhenpumpinglonger

distances.

Use unions at pipe connections to enable easy

removalandservicing.Usesufcienttapeto

ensureairtightsealandhandtightenonly,do

notscrewconnectionsallthewayintosuction

port.Topreventstrainonpumpthreadalways

support heavy inlet and outlet pipes.

Lay suction pipe at a constant gradient to avoid

airpocketswhichmayreducepumpefciency.

Connection to your Water Source

ABOVE GROUND WATER SOURCES

Installationswithoodedsuctionrequireagatevalvesowatersupplycanbe

turned off for pump removal and servicing.

Leavethein-builtone-waycheck

valveinstalledtoavoidwaterdraining

backpastthepumpwhilenotin

operation and causing possible pump

damage.

Connection to your Water Source

BELOW GROUND WATER SOURCES

Prior to using this pump you must ensure that:

• The pump is installed in a safe and dry environment

• The pump enclosure has adequate drainage in the event of leakage

• Any transport plugs are removed

• Thepipe-workiscorrectlysealedandsupported

• The pump is primed correctly

• Thepowersupplyiscorrectlyconnected

• All steps have been taken for safe operation

AppropriatedetailsforalloftheseitemsarecontainedinthefollowingInstallationand

OperatingInstructions.Readtheseintheirentiretybeforeswitchingonthispump.Ifyou

are uncertain as to any of these Installation and Operating Instructions please contact

yourDaveydealerortheappropriateDaveyofceaslistedonthebackofthisdocument.

Choosing a Site

Chooseasitewitharmbaseasclosetothewater

sourceaspossiblewithcorrectpowersupply.Make

sureyourpumpisalwaysconnectedtoanadequate,

reliablesourceofcleanwater.

Housing your Davey Pump

Toprotectyourpumpfromtheweather,make

surethepumphouseisbothwaterproof,frost

free and has adequate ventilation.

Thepumpshouldbemountedonarmbase

allowingfordrainage,toavoiddamageto

ooringetc.,thatovertimemayoccurfrom

leaking pipe joints or pump seals.

Do not mount the pump vertically.

Power Connection

InaccordancewithAS/NZS60335.2.41weareobligedtoinformyouthatthis

pumpisnottobeusedbychildrenorinrmpersonsandmustnotbeusedasa

toy by children.

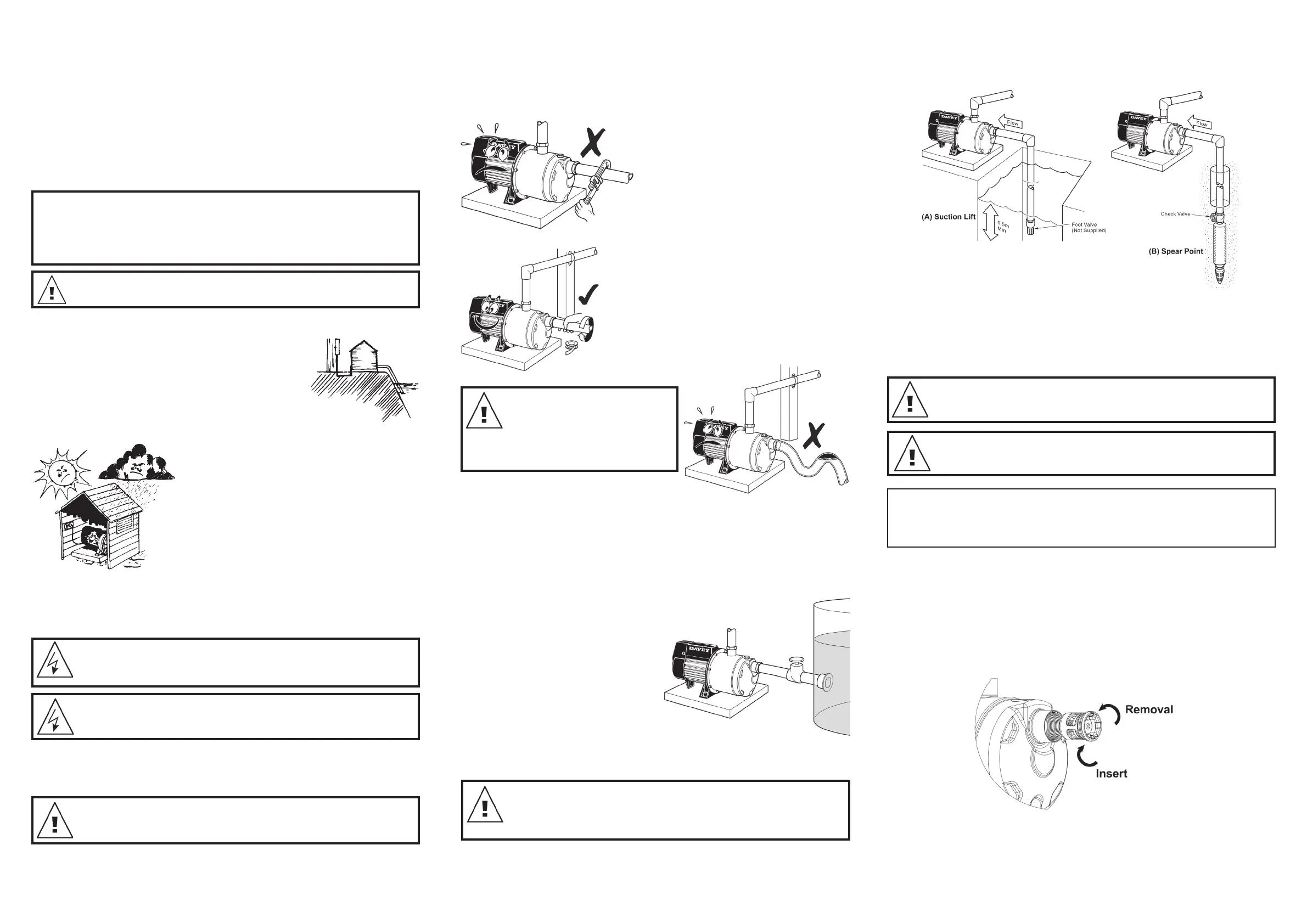

Whenevertheinstallationpositionofthepumpishigherthanthelowestwater

level,afootvalvettedtotheendofthesuctionpipeasillustratedin(A)below

is required. Ensure that the foot valve is at least

1

/

2

metrebelowminimum

waterlevel.

SPEAR POINT INSTALLATIONS

WhenaDynaoHSisinstalledonaspearorwellpoint,thein-builtcheckvalve

MUSTberemovedandacheckvalvettedimmediatelyontopofthespear

pointitself,asshownin(B)above.

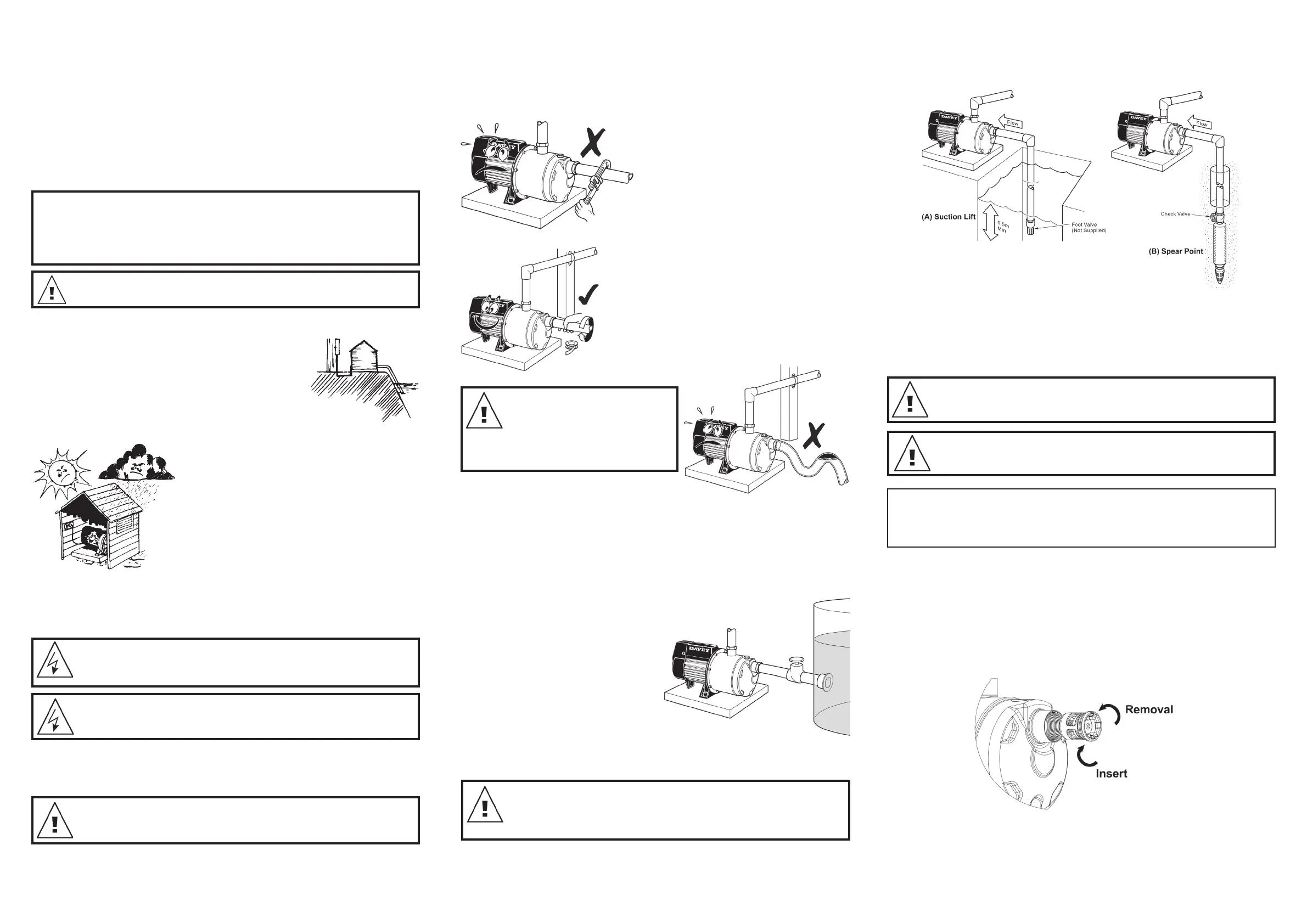

Removal of in-built check valve (wheretted)

If your installation requires the removal of the in-built check valve or the in-

builtcheckvalverequiresremovalforservicing,thiscanbeachievedwithout

difculty.

Thein-builtcheckvalveisacassettedesign,whichisscrewedinthroughthe

suction inlet.

Removal of the check valve cassette is achieved by inserting any suitable tool

(eg:apairofpliersorthehandlefromanadjustingspanner)intotheinlet.

Thecheckvalvecassettehasvariousribsandrecessestoallowavarietyof

nonspecictoolstobeusedintheremovalorinsertionprocess.

Spear Size Mesh Approx. Max. Capacity of Spear Point

1

1

/

4

” (32mm) 60 15-23l/min or 200-300gal/hr

1

1

/

2

” (38mm) 60 23-38l/min or 300-500gal/hr

2” (50mm) 60 38-75l/min or 500-1000gal/hr

Before installing your new pump, please read all instructions carefully as failures

caused by incorrect installation or operation are not covered by the guarantee.

Your Dynao HS Electric Pump is designed to handle clean water. The pump

should not be used for any other purpose without specic referral to Davey.

The use of the pump to pump ammable, corrosive and other materials of a

hazardous nature is specically excluded.

Connect lead to power supply designated on pump label, do not

use long extension leads as they cause substantial voltage drop,

poor pump performance and may cause motor overload.

The electrical connections and checks must be made by a

qualied electrician and comply with applicable local standards.

DO NOT USE THREAD SEALING COMPOUNDS, HEMP OR PIPE

DOPE!

NOTE: Suction leaks are the largest

cause of poor pump performance

and are difcult to detect. Ensure

all connections are completely

sealed using thread tape only.

DO NOT USE SEALING COM-

POUNDS OR PIPE DOPE.

NOTE: DO NOT install the check valve at the pump or at the top of

the well. DO NOT run the pump without water.

NOTE: Be certain to select the spear point to suit the well conditions

and regulate the ow rate from the pump accordingly.

NOTE: Prior to installation remove the red transport plugs & associated seals from

the suction and/or discharge ports.

NOTE: HS models are tted with an in-built suction check valve

which should be removed on all suction lift applications and a

foot valve or check valve installed in the suction pipework as

appropriate.

Loading...

Loading...