21

Data Device Corporation

www.ddc-web.com

RDC-19220 SERIES

P-05/05-0

ORDERING INFORMATION

RDC-1922X_-XXXX (Ceramic Package)

Supplemental Process Requirements:

T = Tape and Reel (Not available in 40-pin DDIP package)

S = Pre-Cap Source Inspection

L = 100% Pull Test

Q = Pre-Cap Source and 100% Pull Test

K = One Lot Date Code

W = One Lot Date Code and Pre-Cap Source Inspection

Y = One Lot Date Code and 100% Pull Test

Z = One Lot Date Code, Pre-Cap Source Inspection and 100% Pull Test

Blank = None of the Above

Accuracy:

2= 4 minutes + 1 LSB

3 = 2 minutes + 1 LSB

Process Requirements:

0 = Standard DDC Processing, without Burn-In

1 = MIL-PRF-38534 Compliant

2 = Standard DDC Processing, with Burn-In

3 = MIL-PRF-38534 Compliant, with PIND testing

4 = MIL-PRF-38534 Compliant, with Solder Dip

5 = MIL-PRF-38534 Compliant, with PIND testing, and Solder Dip

6 = Standard DDC Processing, with PIND testing, and Burn-In

7 = Standard DDC Processing, with Solder Dip, and Burn-In

9 = Standard DDC Processing, with Solder Dip, without Burn-In

Temperature Grade / Data Requirements:

1 = -55 to +125°C

4 = -55 to +125°C, with Variables Test Data

Package Options:

Blank = Standard

G = Lead free

Package:

0 = 40-Pin DDIP, (“+5 volt only” power supply feature - not available)

2 = 44-Pin J-Lead

External Component Selection Software (refer to General Setup

Conditions section) can be downloaded from DDC’s web site:

www.ddc-web.com.

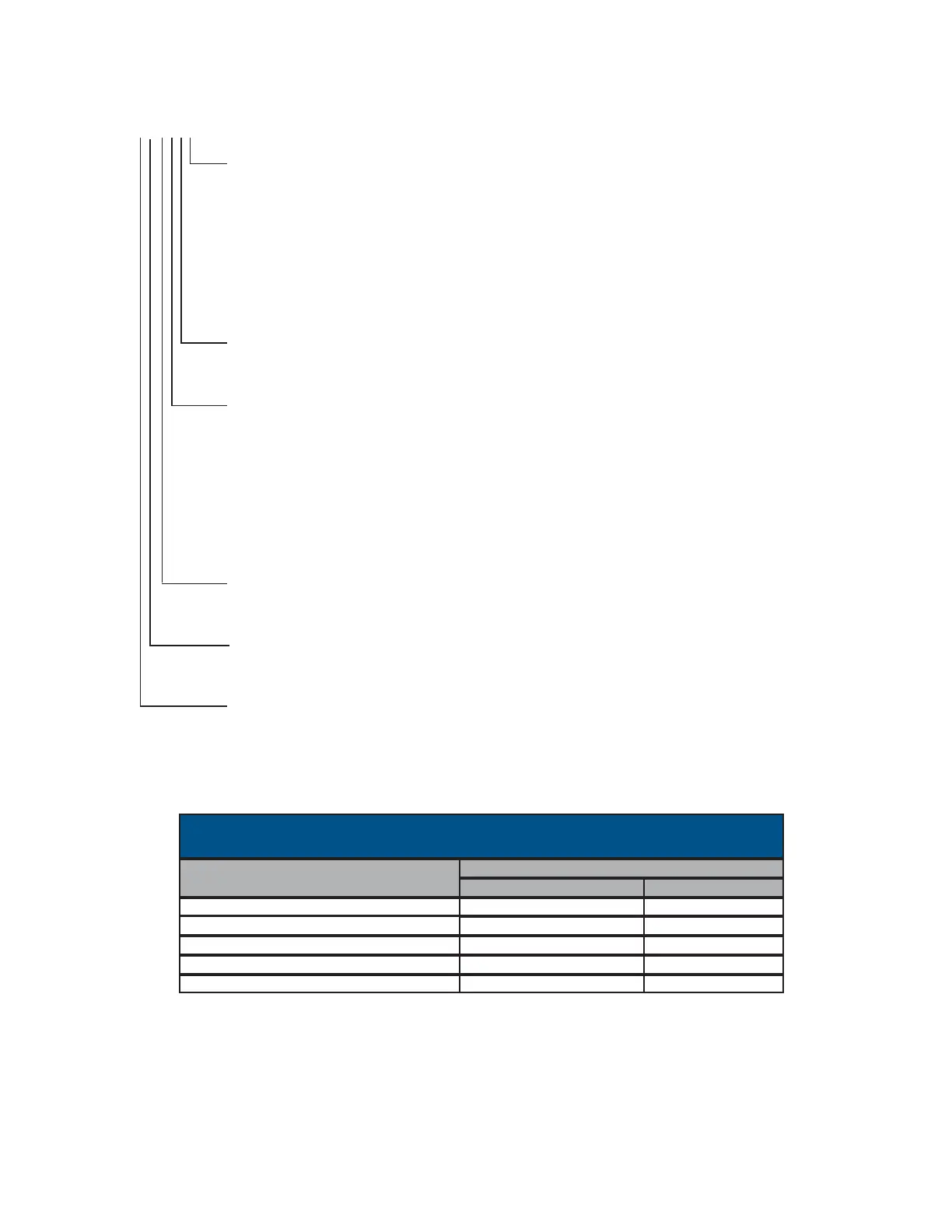

TABLE 11015

(note 1)

, 1030

(note 2)

BURN-IN

Notes:

1. For Process Requirement "B*" (refer to ordering information), devices may be non-compliant with MIL-

STD-883, Test Method 1015, Paragraph 3.2. Contact factory for details.

2. When applicable.

3000g

2001CONSTANT ACCELERATION

C1010TEMPERATURE CYCLE

A and C1014

SEAL

—2009, 2010, 2017, and 2032INSPECTION

CONDITION(S)METHOD(S)

MIL-STD-883

TEST

STANDARD DDC PROCESSING

FOR HYBRID AND MONOLITHIC HERMETIC PRODUCTS

Loading...

Loading...