Dectron, Inc. March 2012

DECTRON

DSH/DSV/RSH/DBH/RBH Series Dehumidifier Owner’s Manual

Operation Maintenance Motor Lubrication

Data subject to change without notice.

258

Some smaller motors may be permanently lubricated. Other electric

motors may have grease fittings and grease outlet plugs. Use the

lubricating instructions provided on the motor nameplate or in

accompanying documents. If no instructions are available, then until

the proper instructions can be obtained

a) use Shell Dolium R or Chevron SRI grease, and

b) once per year use the following instructions:

1. Be sure the electric power to the unit is OFF, locked out, and

tagged out.

2. Clean all grease fittings or plugs to remove any paint, dirt, or dust.

3. Clean any dirt or old grease from around a grease outlet plug.

4. Remove and retain the grease outlet plug. Do not allow it to

become dirty.

5. Use a small clean round brush to clean out any hardened grease

that may have accumulated in the grease outlet.

6. Does the motor have a grease fitting or a screw-plug for adding grease?

Grease Fitting Screw Plug

7. Repeat steps 1-9 for the bearing at the other end of the shaft.

8. Close all doors and access panels and, if safe to do so, allow the motor to run at full load for

about 30 minutes.

9. Again be sure the electric power to the unit is OFF, locked out, and tagged out.

10. Wipe off any excess grease that has appeared on the outside of the motor or shaft.

11. Clean and re-install the grease outlet plug.

12. If safe and practical to do so, return the motor to operation.

Risk of contact with moving parts. Can cause injury or death.

This product contains rotating parts and V-belt drives. Some procedures could

expose personnel to the risk of injury or death from contact with these parts.

Using only approved devices (e.g. locking safety switch), disconnect, lockout, and

tagout all sources of electrical energy before working inside the unit cabinet. Allow

adequate time for rotating parts to stop. Follow all applicable safety regulations.

Do not operate the unit until ductwork or a screen is installed at each blower outlet.

WARNING

grease outlet plug

grease fitting

or screw plug

6a. NEMA 215 Frame and smaller - add 1 or 2

gun strokes

NEMA 254 -365 Frame - add 2 or 3

gun strokes

NEMA 404 Frame and larger - add 3 or 4

gun strokes

Stop if grease begins to come out of the

grease outlet or around the shaft. Do not

over-grease. Do not get grease on belts.

6b. Wipe off any excess grease.

6c. If possible, put a plastic cap over the

grease fitting to keep it clean.

6a. Remove grease plug.

6b. NEMA 215 Frame and smaller - add a 2 or 3-

inch string of grease

NEMA 254 Frame and larger - add a 3 to 5-

inch string of grease

6c. Wipe off any excess grease. Do not

get

grease on belts.

6d. Re-install grease plug.

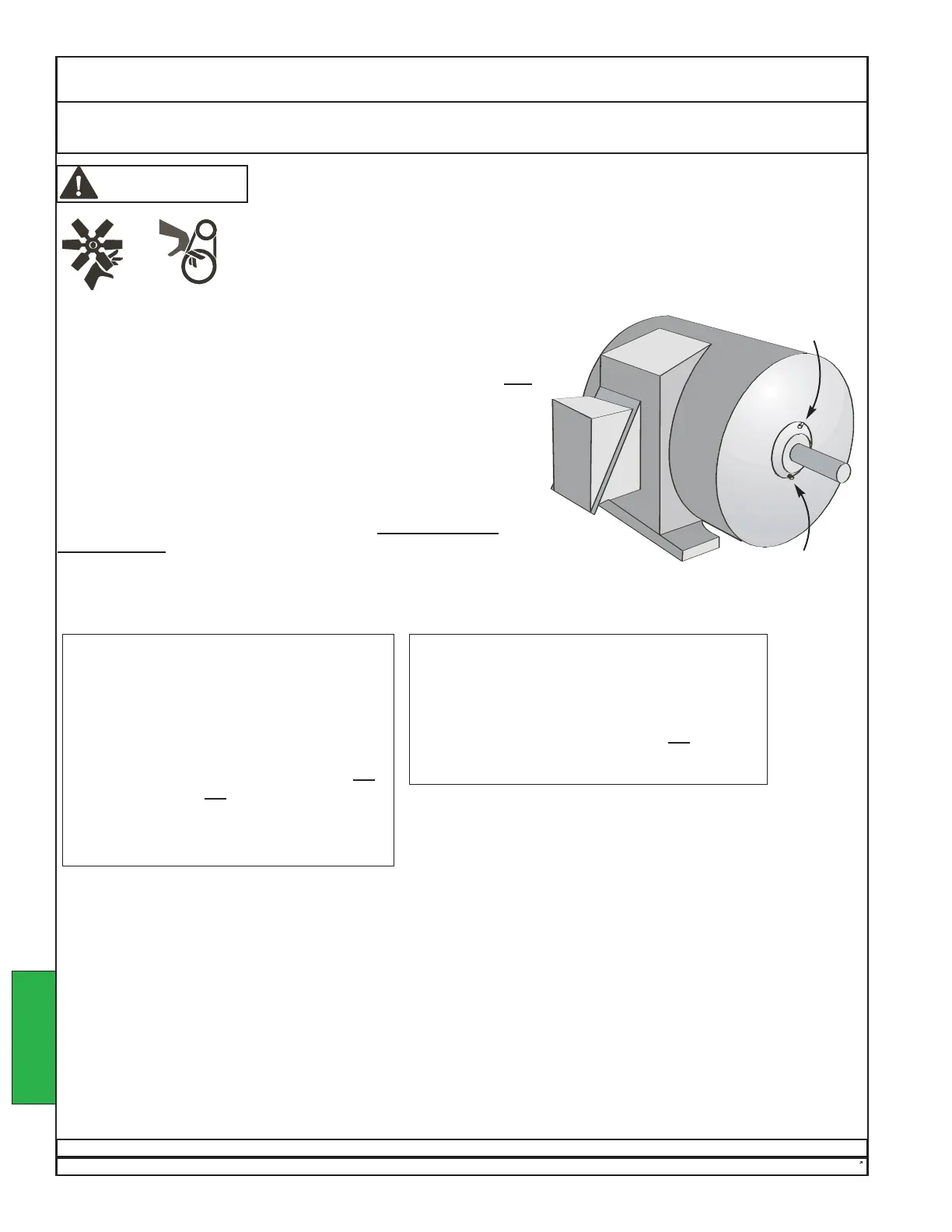

Sample

Appearance

may vary.

OPERATION

Loading...

Loading...