Dectron, Inc. March 2012

DECTRON

DSH/DSV/RSH/DBH/RBH Series Dehumidifier Owner’s Manual

Data subject to change without notice.

310

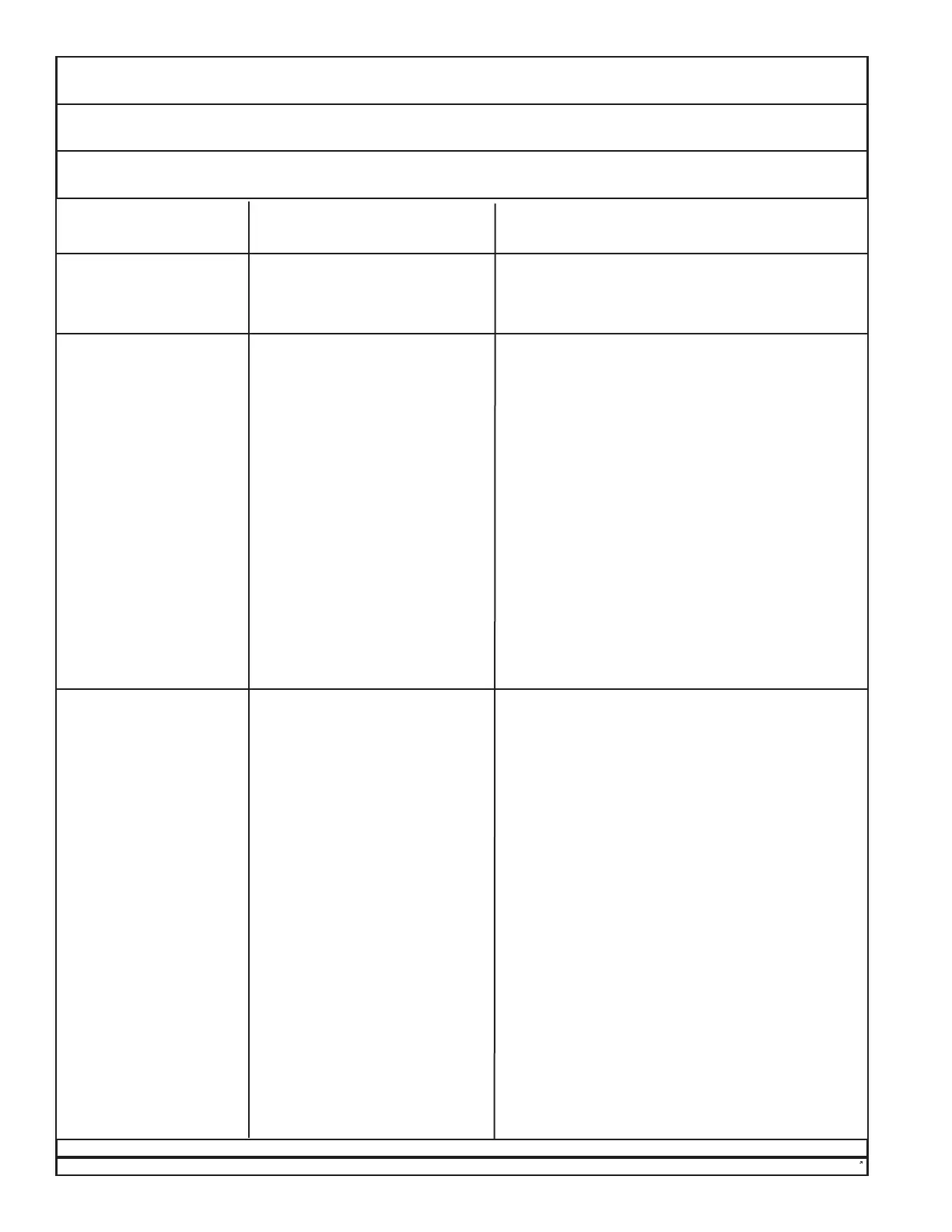

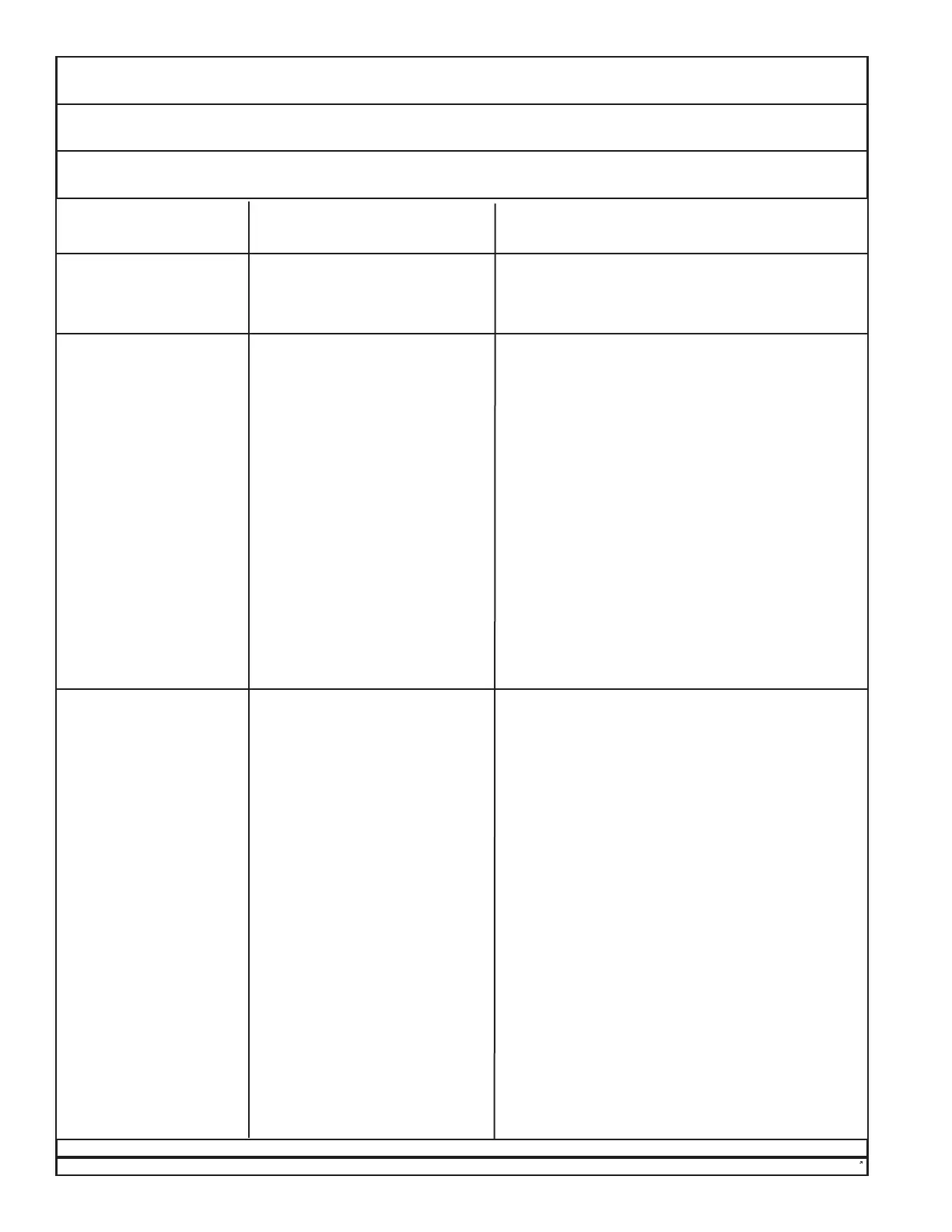

Service Diagnostics - Mechanical

High suction pressure

(continued)

A worn or damaged compressor

may produce less refrigerant

pumping.

• Compare compressor current to value

shown on value shown on unit nameplate.

Excessive noise

Lack of unit support isolators

allows vibration to be transmitted

to floors, etc.

• See the Installation section of this manual

for proper design.

Lack of duct isolators allows

vibration to be transmitted to the

ducts.

• See the Installation section of this manual

for proper design.

Loose blower belts and/or pulleys

can produce unexpected noise.

• Check blower belts and pulleys for proper

tension and alignment.

Improperly closed access panels

can produce a whistling noise as

air leaks into the cabinet.

• Be sure that all panels are closed tightly

and that all gaskets are in place.

An incorrectly set expansion

valve can cause liquid refrigerant

flood back to the compressor

with accompanying noise.

• Adjust the expansion valve to produce at

least 160°F compressor discharge gas

temperature.

Evaporator icing

Dirty air filters reduce airflow

• Replace dirty filters.

Low room temperature

• Adjust set points to value shown on unit

nameplate.

• Close evaporator-bypass damper when air

is below 78°F.

Low airflow

• Assure blower turns proper direction (three-

phase units only).

Low refrigerant charge

• Add refrigerant to eliminate bubbles in the

sight glass in all modes.

Improper duct design

• See the Installation section of this manual

for proper design.

• Assure blower belt tension is right.

SYMPTOM POSSIBLE CAUSES CHECKS & CORRECTIONS

Problems not indicated by Supervisaire

®

Controller

Loading...

Loading...