6

ADJUSTING GUIDE BAR

TO TABLE SLOT

CAUTION: DISCONNECT MACHINE FROM POWER

SOURCE.

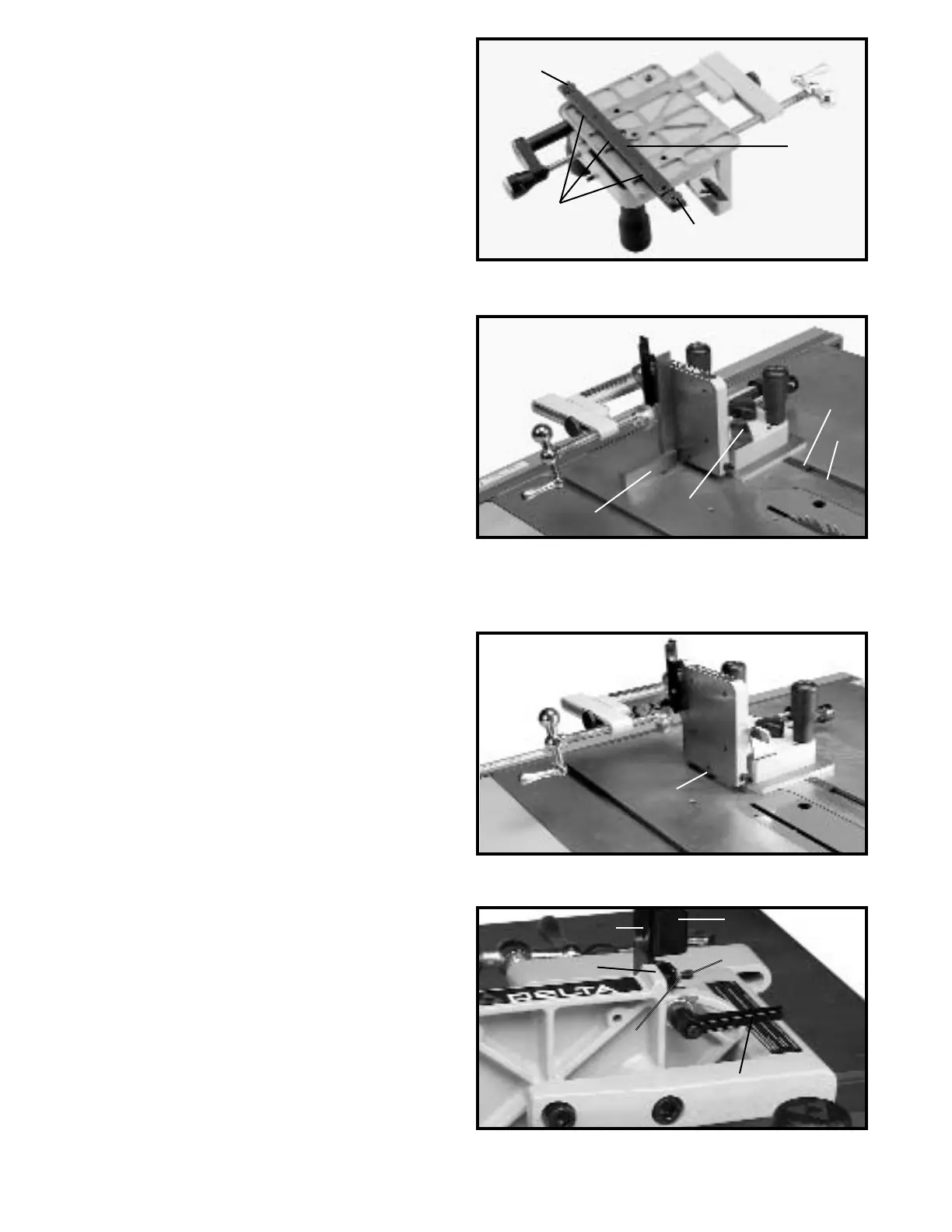

1. The tenoning jig is furnished with an adjustable guide

bar (A) Fig. 12, which allows the jig to be custom-fit to

your saw, eliminating any side-to-side play. Also, there is

a T-slot washer (B) on each end of the guide bar (A) to

keep the tenoning jig from lifting during operation.

NOTE: T-slot washers (B) need to be removed if your

table saw is not equipped with T-slotted miter gage slots.

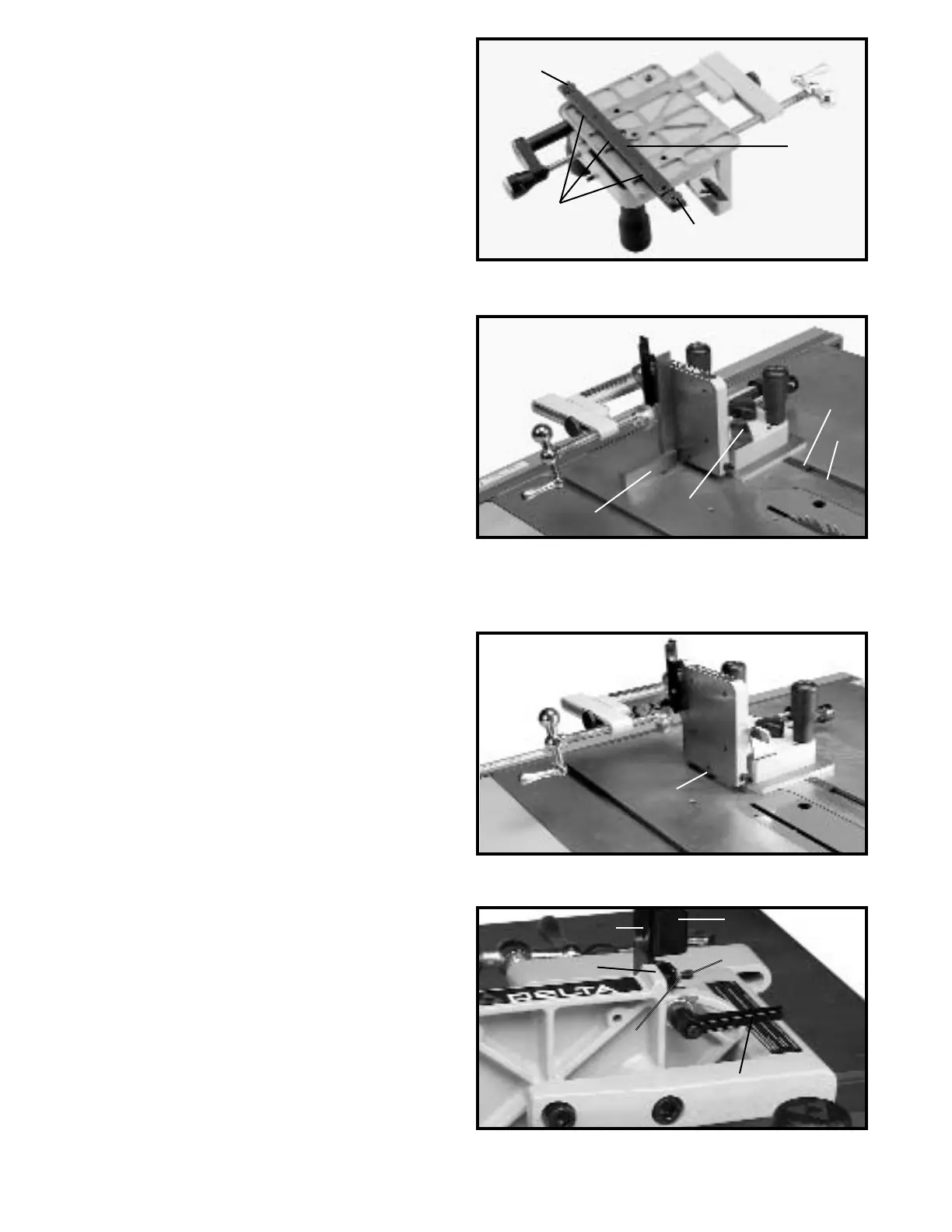

2. Place tenoning jig guide bar (A) Fig. 13, into left miter

slot (D) of machine as shown and slide miter gage back

and forth to determine if there is any side-to-side play. If

there is no side-to-side play and the tenoning jig slides

easily through the miter slot of the machine, no

adjustment is necessary; however, if the tenoning jig fits

too snugly, or if there is excessive play between the

guide bar (A), and miter slot (D) of the machine, proceed

as follows:

3. Remove tenoning jig from machine and place it

upside down as shown in Fig. 12.

4. Using the 2.5mm allen wrench (not shown) adjust

screws (C) Fig. 12, clockwise to eliminate play, or

counter-clockwise to provide a looser fit between the

guide bar (A) Fig. 13, and miter slot (D). Then insert the

tenoning jig back into the miter slot of the machine and

determine that fit is suitable, or if further adjustments are

required.

Fig. 12

Fig. 13

ALIGNING TENONING JIG

CAUTION: DISCONNECT MACHINE FROM POWER

SOURCE.

1. Place the tenoning jig guide bar (A) Fig. 13, into the

left miter gage slot.

2. Using a square (E) Fig. 13, check to see if the vertical

work support plate (F) is 90 degrees to the saw table. If

an adjustment is necessary, loosen lock handle (G),

move vertical work support plate (F) until it is 90 degrees

to the table and tighten lock handle (G).

3. With the vertical work support plate (F) Fig. 14,

adjusted at 90 degrees to the table, tighten set screw (H)

until it bottoms. This positive stop set screw (H) enables

you to rapidly position the vertical work support (F) 90

degrees to the table after it has been tilted.

4. The tenoning jig features a positive stop to ensure

fast and accurate positioning of the backstop (G) Fig. 15,

at 90 degrees to the saw table. To check and adjust the

positive stop at 90 degrees, loosen lock knob (H) Fig. 15,

and place one end of a combination square (J) on the

saw table and the other end against backstop (G). Check

to see if the backstop is at 90 degrees to the saw table.

If an adjustment is necessary, loosen locknut (K) Fig. 15,

and adjust screw (L) until head of screw contacts the

casting on vertical plate (M) at 90 degrees. Tighten

locknut (K) and lock knob (H) after adjustment is made.

Fig. 14

Fig. 15

A

B

B

C

D

A

G

E

F

F

H

H

K

L

M

J

G

Loading...

Loading...