Example of calculation for charger with 150kW DC charge capacity, 22kW AC and 43kW AC charge capacity:

𝐼𝑛𝑜𝑚 = 12 × 19,29 + 32 + 63 + 1 = 327 𝐴

𝐼𝑚𝑎𝑥 = 12 × 21,43 + 32 + 63 + 2 = 354 𝐴

Note! Charger controller will limit I

max

current to 336A.

The recommended minimal cable cross section accepted by charger terminals is 95mm

2

. The maximal cable

cross section accepted by terminals is 300mm

2

. Site planning needs to check if the cable diameter and

bending radius is suitable for cable glands and plinth dimensions.

Use of aluminium cable is prohibited. The charger is cyclic load resulting to cycling thermal expansion and

contraction of cables. This increase risk of hotspots. During annual maintenance, check the cable connection

in charger and also in distribution board.

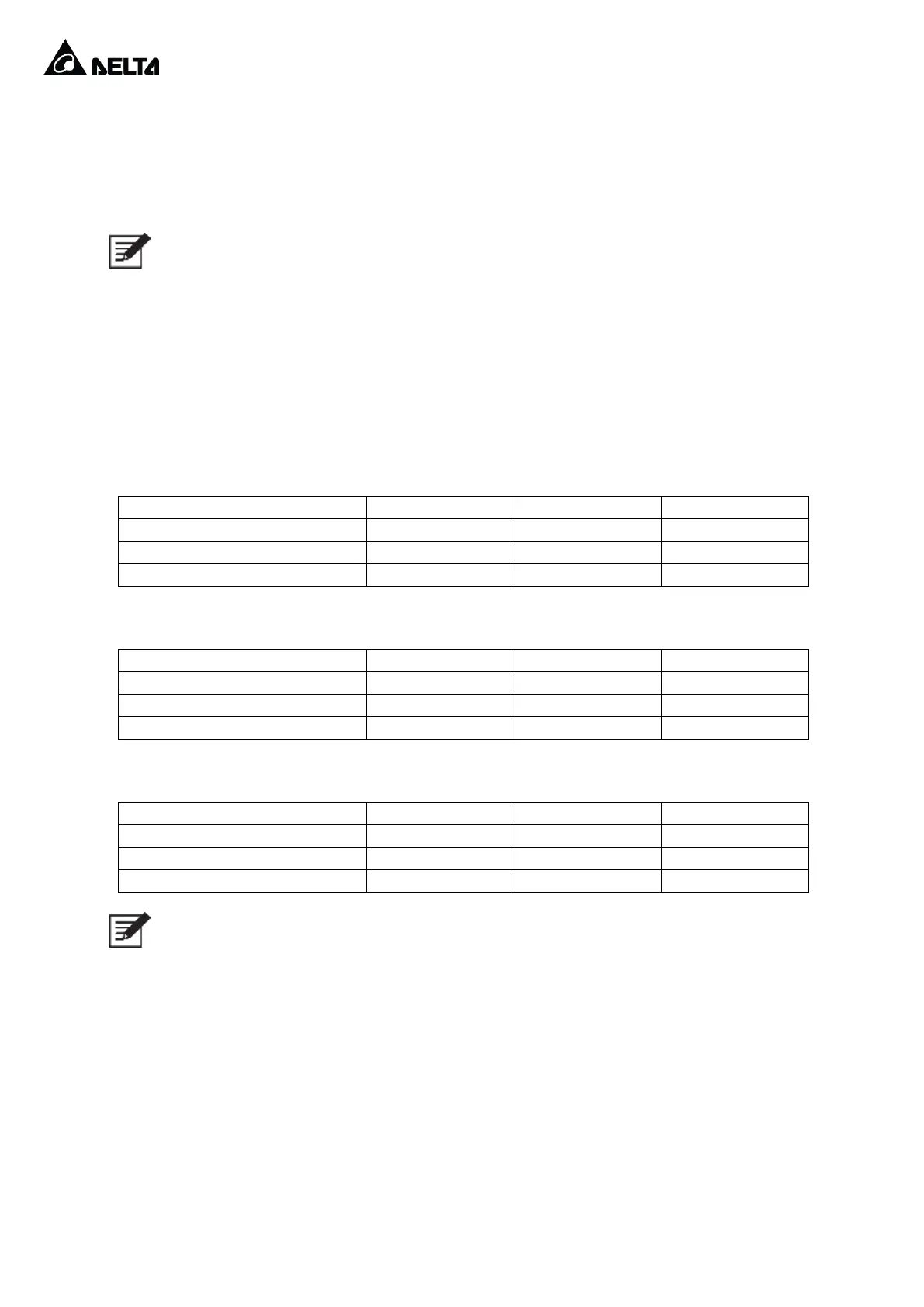

Available AC connection – current rating for EV QC with DC plugs, AC 22kW.

Available AC connection – current rating for EV QC with DC plugs, AC 43kW.

Available AC connection – current rating for EV QC with DC plugs, AC 43kW and AC 22 kW.

Note! Cable cross section is based on IEC 60364-5-52:2011 standard (Cu conductor, multi-core

cable, 3 live cores, PVC insulation, in the earth – D2 case). Site specific conditions must be taken

into account for proper dimensioning. For different types of cables and installation conditions please

refer to cable fact sheet or consult with Delta customer service.

4.1.2 Required cable length

Installation site should be prepared with AC cabling to supply L1, L2, L3, N, PE. Cable length should be at

least 1,5 meter long from base. Cable should be prepared inside the footprint of the EV quick Charger. Check

exact cable location in chapter 4.5.3

Loading...

Loading...