Chapter 16 PLC Function ApplicationsC2000-HS

16-138

frequency will also be automatically sent back to the master station (D2009+n*100 and

D2013+n*100). This also illustrates how the master can handle these tasks through read/write

operations in the special D area.

Furthermore, it should be noted that the remote I/O of PDO2 can obtain the slave device's current

DI and AI status, and can also control the slave device's DO and AO status. Nevertheless, after

introducing a fully automatic mapping special D, the C2000-HS CANopen master also provides

additional information refreshes. For instance, while in speed mode, acceleration/deceleration

settings may have been refreshed. The special D therefore also stores some seldom-used

real-time information, and these commands can be refreshed using the CANFLS command. The

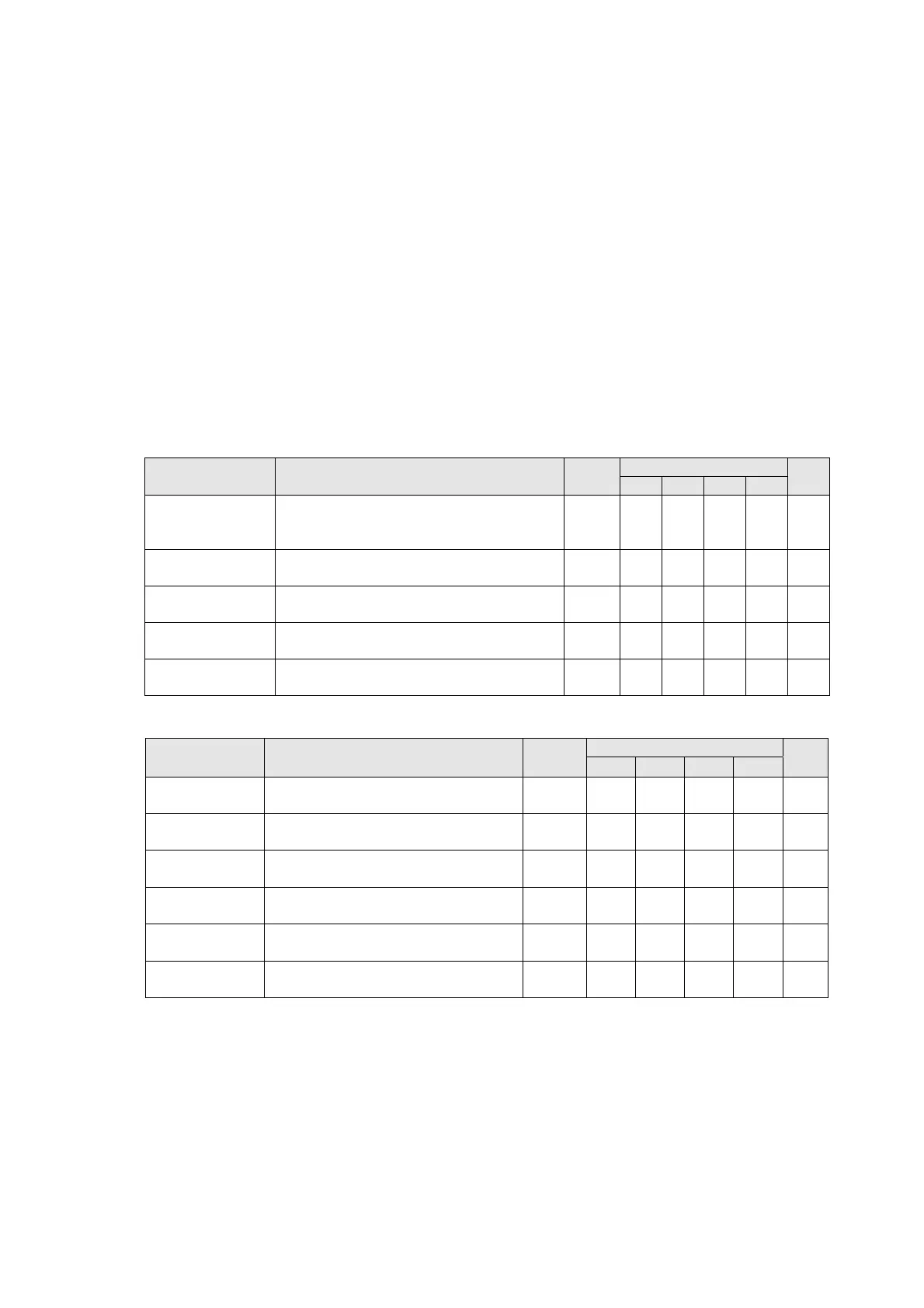

following is the C2000-HS's current CANopen master data conversion area, which has a range of

D2001+100*n–D2033+100*n, as shown below:

1. The range of n is 0–7

2. ●Indicates PDOTX, ▲Indicates PDORX; unmarked special D can be refreshed using the

CANFLS command

Special D Description of Function Default

PDO Default

R/W

1 2 3 4

D2000+100*n

Station number n of slave station

Setting range: 0–127

0: No CANopen function

0 RW

D2002+100*n

Manufacturer code of slave station

number n (L)

0 R

D2003+100*n

Manufacturer code of slave station

number n (H)

0 R

D2004+100*n

Manufacturer's product code of slave

station number n (L)

0 R

D2005+100*n

Manufacturer's product code of slave

station number n (H)

0 R

Basic definitions

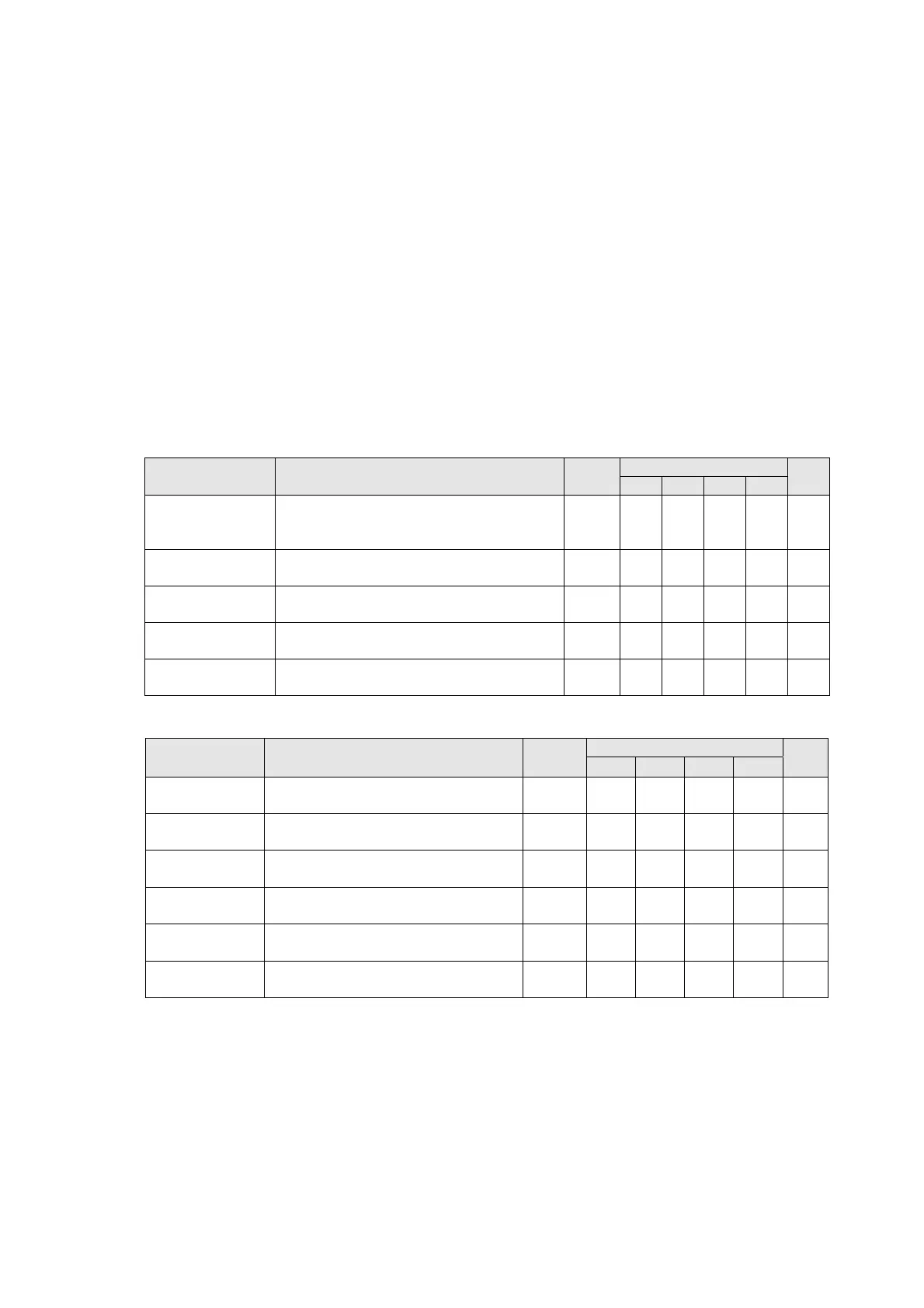

Special D Description of Function Default

PDO Default

R/W

1 2 3 4

D2006+100*n

Communications break handling

method of slave station number n

0 RW

D2007+100*n

Error code of slave station number n

error

0 R

D2008+100*n

Control word of slave station number

n

0 ● ● ● RW

D2009+100*n

Status word of slave station number

n

0 ▲ ▲ ▲ R

D2010+100*n

Control mode of slave station

number n

2 RW

D2011+100*n

Actual mode of slave station number

n

2 R

Loading...

Loading...