Chapter 16 PLC Function Applications│CP2000

16-18

Ladder diagram

structures

Explanation of commands Command Using Device

Coil driven output

commands

OUT

Y、M

Some basic commands,

applications commands

Some basic

commands

Applications

commands

Inverted logic INV N/A

16-4-3 Overview of PLC ladder diagram editing

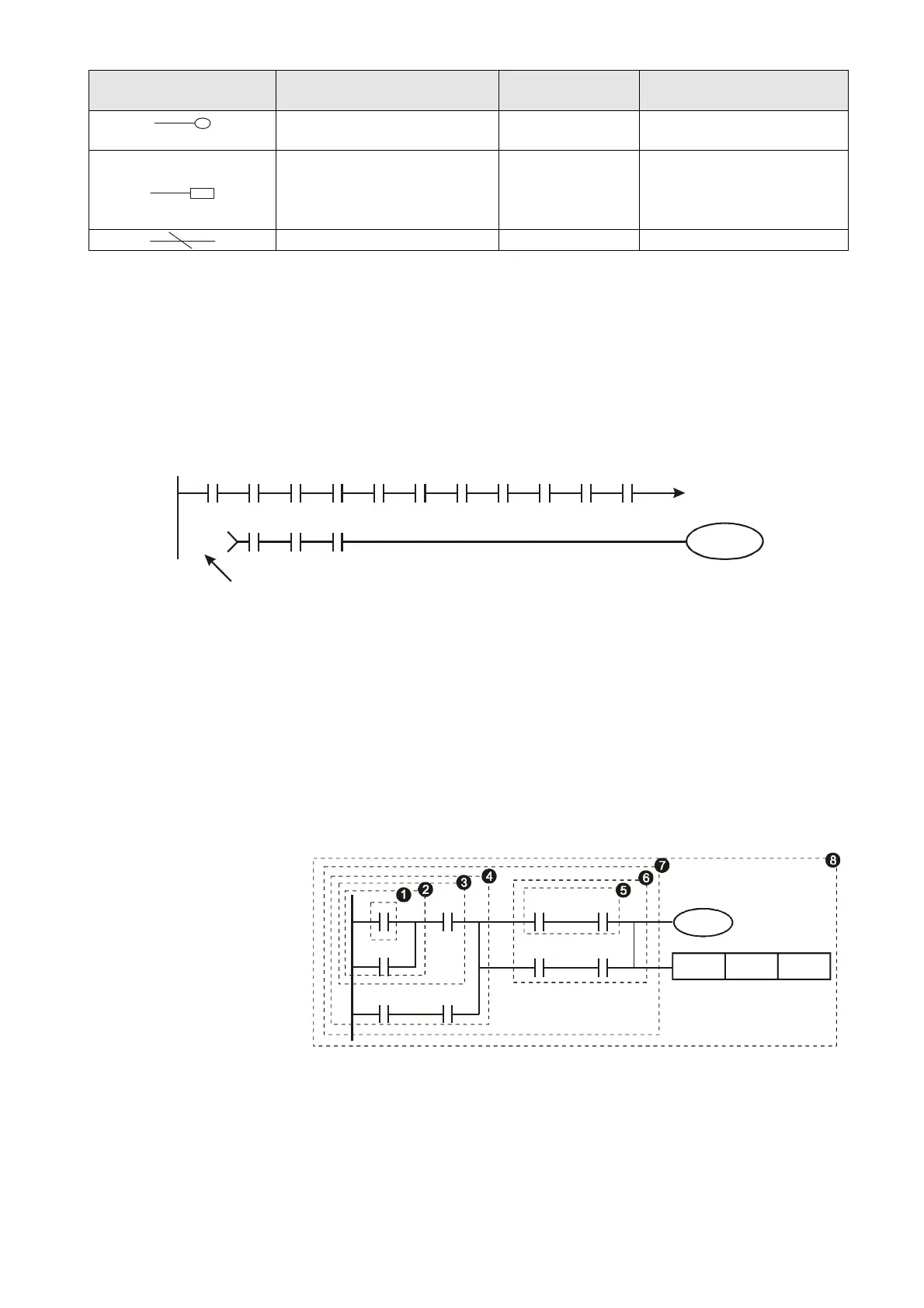

The program editing method begins from the left busbar and proceeds to the right busbar (the

right busbar is omitted when editing using WPLSoft). Continue to the next row after completing each

row; there is a maximum of 11 contacts on each row. If this is not sufficient, a continuous line will be

will be generated to indicate the continued connection and more devices can be added. A continuous

series of numbers will be generated automatically and identical input points can be used repeatedly.

See figure below:

X0 X1 X2 X3 X4 X5

Y0

X11 X12 X13

X6 X7 X10 C0 C1

00000

00000

Row Number

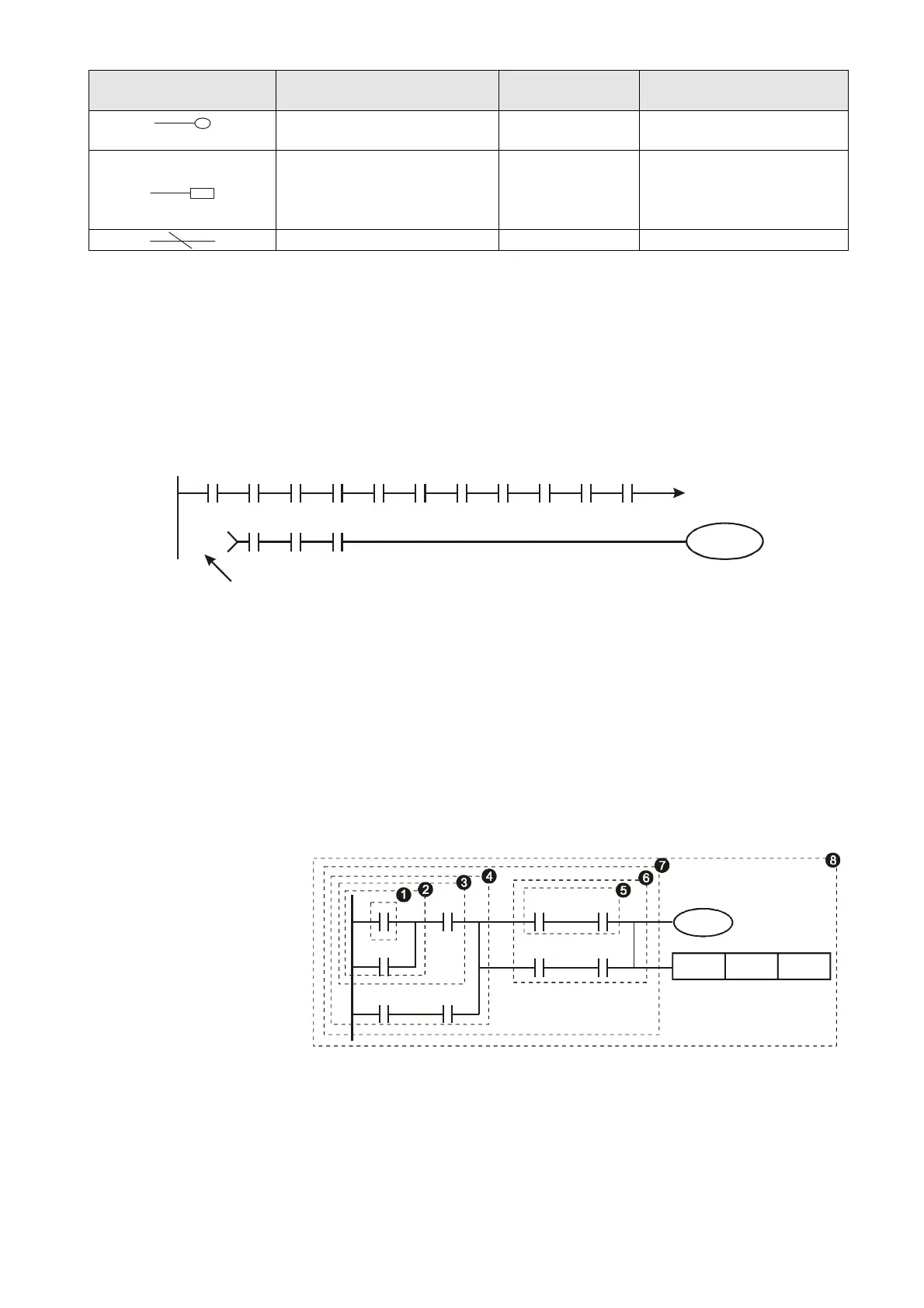

The ladder diagram programming method involves scanning from the upper left corner to the

lower right corner. The coils and applications command computing box are handled in the output, and

the ladder diagram is placed on the farthest right. Taking the figure below as an example, we can

gradually analyze the procedural sequence of the ladder diagram. The number in the upper right

corner gives the sequential order.

Explanation of command sequence

X0 X1 Y1 X4

M0

X3

M1

T0

M3

Y1

TMR

T0

K10

1 LD X0

2 OR M0

3 AND X1

4 LD X3

AND M1

ORB

5 LD Y1

AND X4

6 LD T0

AND M3

ORB

7 ANB

8 OUT Y1

TMR T0 K10

Loading...

Loading...