Chapter 13 Warning CodesCP2000

13-12

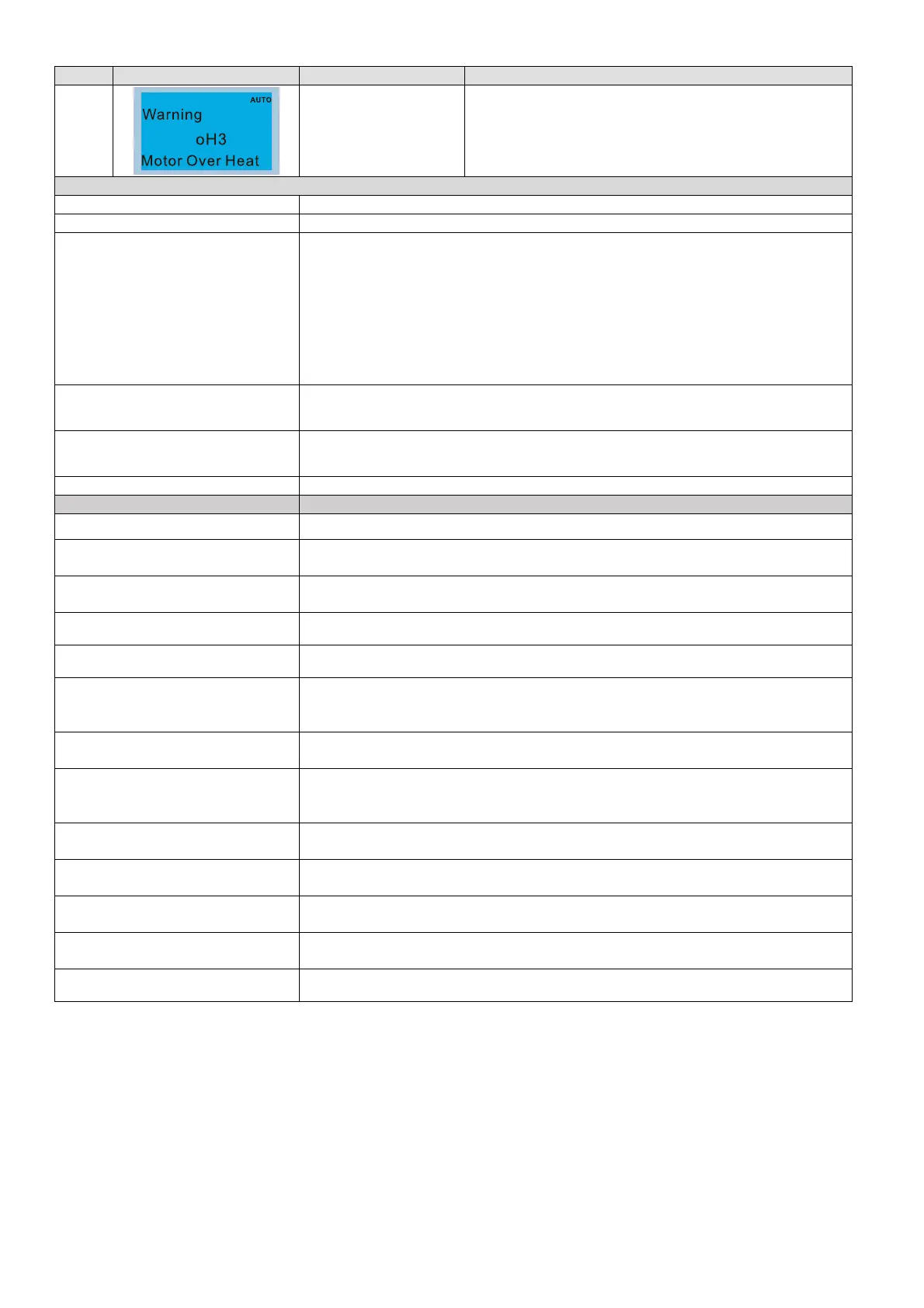

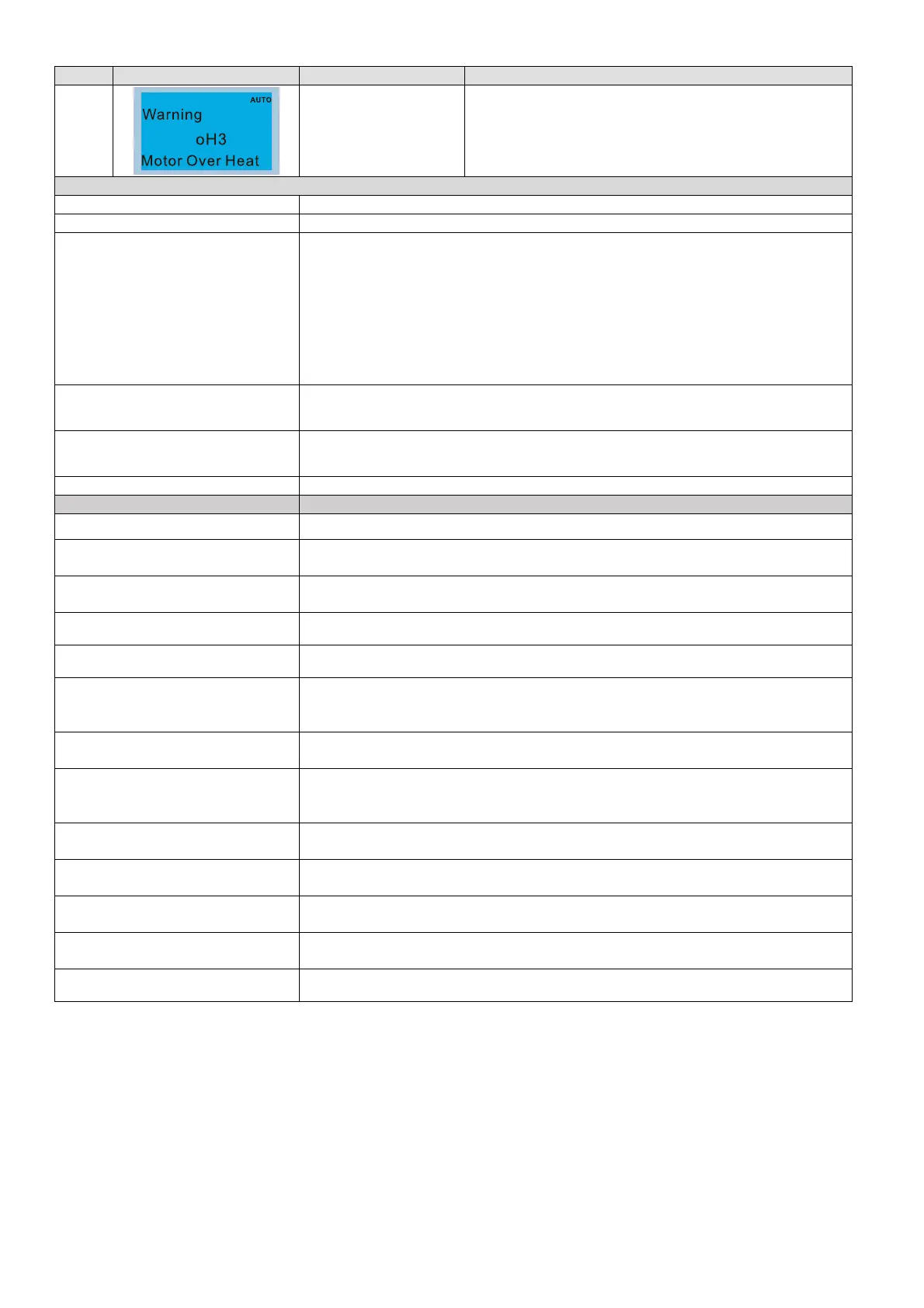

ID No. Display on LCD Keypad Warning Name Description

22_1

Motor over-heating

(oH3) PTC

Motor over-heating warning.

The AC motor drive detects the temperature inside the

motor is too high

Action and Reset

Action level Pr.03-00=6 (PTC), PTC input level > Pr.06-30 (default=50%)

Action time Immediately act

Warning setting parameter

Error treatment: Pr.06-29

0: Warn and keep operating

1: Fault and ramp to stop

2: Fault and coast to stop

3: No warning

When Pr.06-29=0 and when the temperature is ≦ Pr.06-30 level, the oH3

warning automatically clears.

When Pr.06-29=0 (“Warning”), it automatically resets.

Reset method

When Pr.06-29=0, oH3 displays “Warning”. When the temperature is ≦

Pr.06-30 level, the oH3 warning automatically clears.

Reset condition

When the temperature is ≦ Pr.06-30 level, the oH3 warning automatically

clears.

Record N/A

Cause Corrective Actions

Motor locked Clear the motor lock status.

The load is too large

Decrease the loading.

Replace with a motor with larger capacity.

Ambien temperature is too high

Change the installed place if there are heating devices in the surroundings.

Install/ add cooling fan or air conditioner to lower the ambient temperature.

Motor cooling system error Check the cooling system to make it work normally.

Motor fan error Replace the fan.

Operates at low-speed too long

Decrease low-speed operation time.

Change to dedicated motor for the drive.

Increase the motor capacity.

Accel./ Decel. time and working

cycle is too short

Increase setting values for Pr.01-12–01-19 (accel./ decel. time).

V/F voltage is too high

Adjust settings for Pr.01-01–01-08 (V/F curve), especially the setting value for

the mid-point voltage (if the mid-point voltage is set too small, the load capacity

decreases at low-speed).

Check if the motor rated current

matches the motor nameplate

Configure the correct rated current value of the motor again.

Check if the PTC is properly set

and wired

Check the connection between PTC thermistor resistor and the heat protection.

Check if the setting for stall

prevention is correct

Set the stall prevention to the proper value.

Unbalance three-phase

impedance of the motor

Replace the motor.

Harmonics is too high Use remedies to reduce harmonics.

Loading...

Loading...