Commissioning and Maintenance CAIRplus

64 PR-2009-0096-GB • Subject to modifications • R8-10/2015

Carry out the following maintenance and inspection steps:

• Check fan for secure mounting.

• Check fans for dirt, damage and corrosion.

• Check anti-vibration isolators for proper operation

• Check belt protection grille for proper operation, clean if necessary.

• Check impeller for unbalanced condition.

Re-tensioning or replacing V-belt

Initial check:

• Perform the initial check following 50 hours of operation

Regular checks: Subsequent checks depend on the operating load and experience.

• Check every three months, if the unit operates on a regular daily basis (approx. 8

hrs a day).

• With higher operating hours perform more frequent inspections.

Fig. 8-1: High-performance narrow V-belt as per DIN 7753

• Inspect the belt for tension and wear, re-tension or replace if required.

To re-tension the belt using the motor mounting plate or replace:

• Slacken the counter nuts of the set bolts.

• Replace the belt , if required.

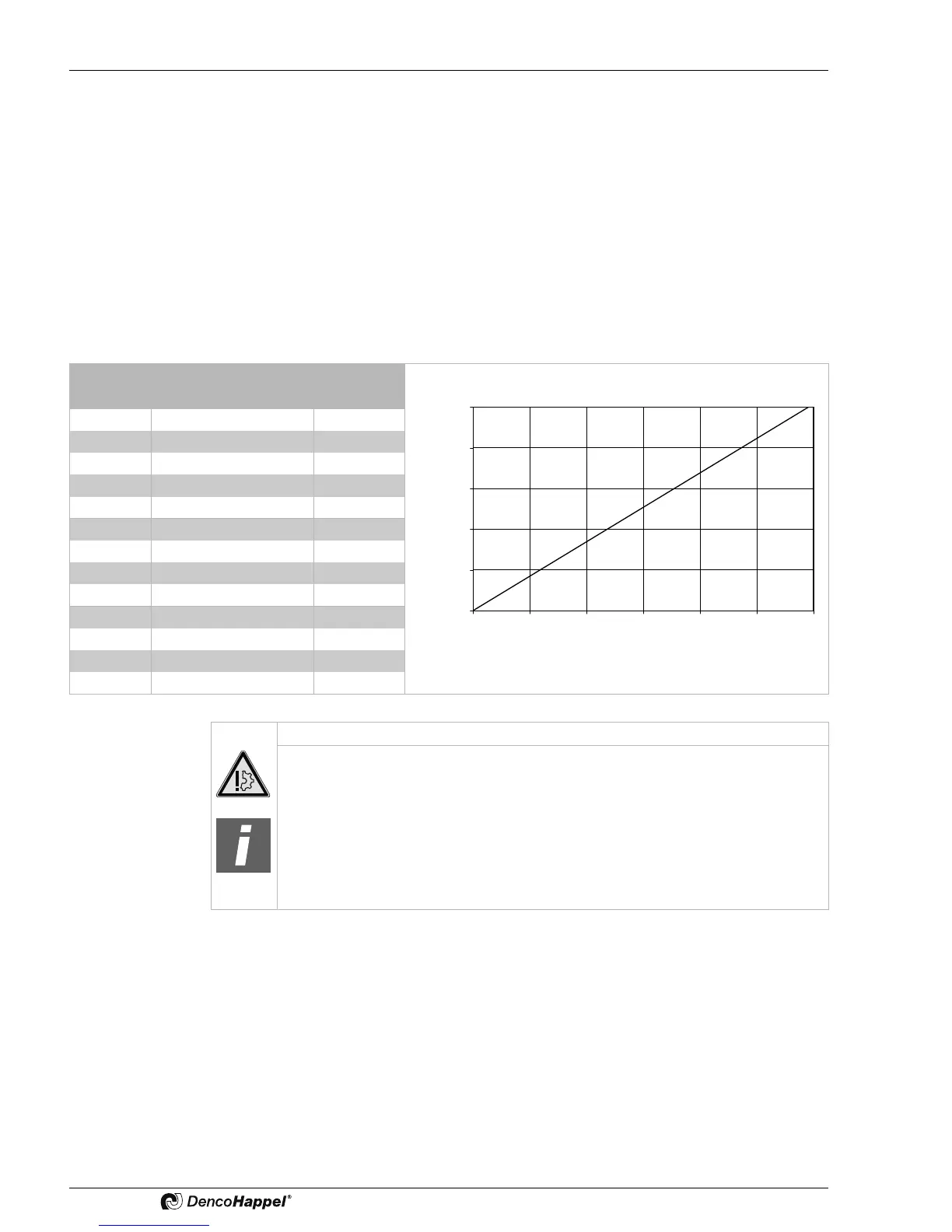

• Check the pulley alignment and adjust, if required (fig. 8-2).

• Tension the fan belt (measure using a belt tensiometer or frequency calculation

method, fig. 8-2).

• Tighten counter nuts.

An acceptable belt deflection at a load of P = 20-30 N is from 5 to 20 mm, depending

on the axis distance (see fig. 8-2).

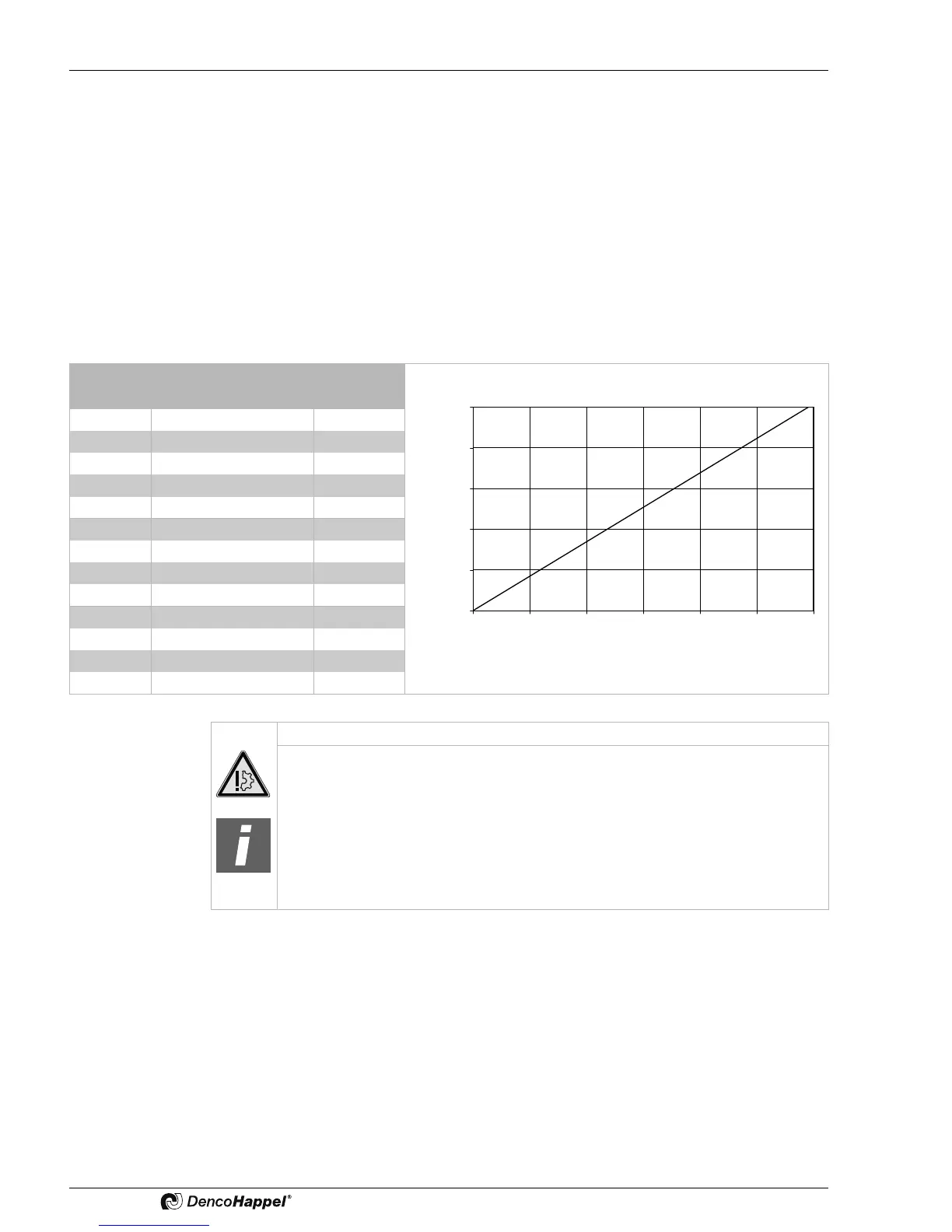

Belt

profiles

Smallest pulley

diameter (mm)

F force

(N/belt)

SPZ 70 – 85 13 – 19

86 – 155 15 – 23

116 – 150 19 – 27

151 – 200 25 – 24

201 – 250 29 – 38

SPA 112 – 150 25 – 34

151 – 200 29 – 38

201 – 250 35 – 44

251 – 300 40 – 50

SPB 180 – 224 40 – 52

225 – 300 46 – 60

301 – 400 55 – 76

401 – 500 67 – 90

ATTENTION

Equipment damage and notice

• Always reduce the distance between the axes to the point where the V-belt

can be placed in grooves without applying force. It is not allowed to use

crow bars, screwdrivers or similar tools for belt mounting.

• If the V-belt pulleys are fitted with several grooves, replace all V-belts.

• Do not use a belt set consisting of belts from different manufacturers.

• Belts do not require any special maintenance. Avoid using belt wax and

belt spray.

Loading...

Loading...