12 © 2013 Finishing Brands UK Ltd.

Parts Replacement/

Maintenance

SPRAY HEAD SEAL

REPLACEMENT

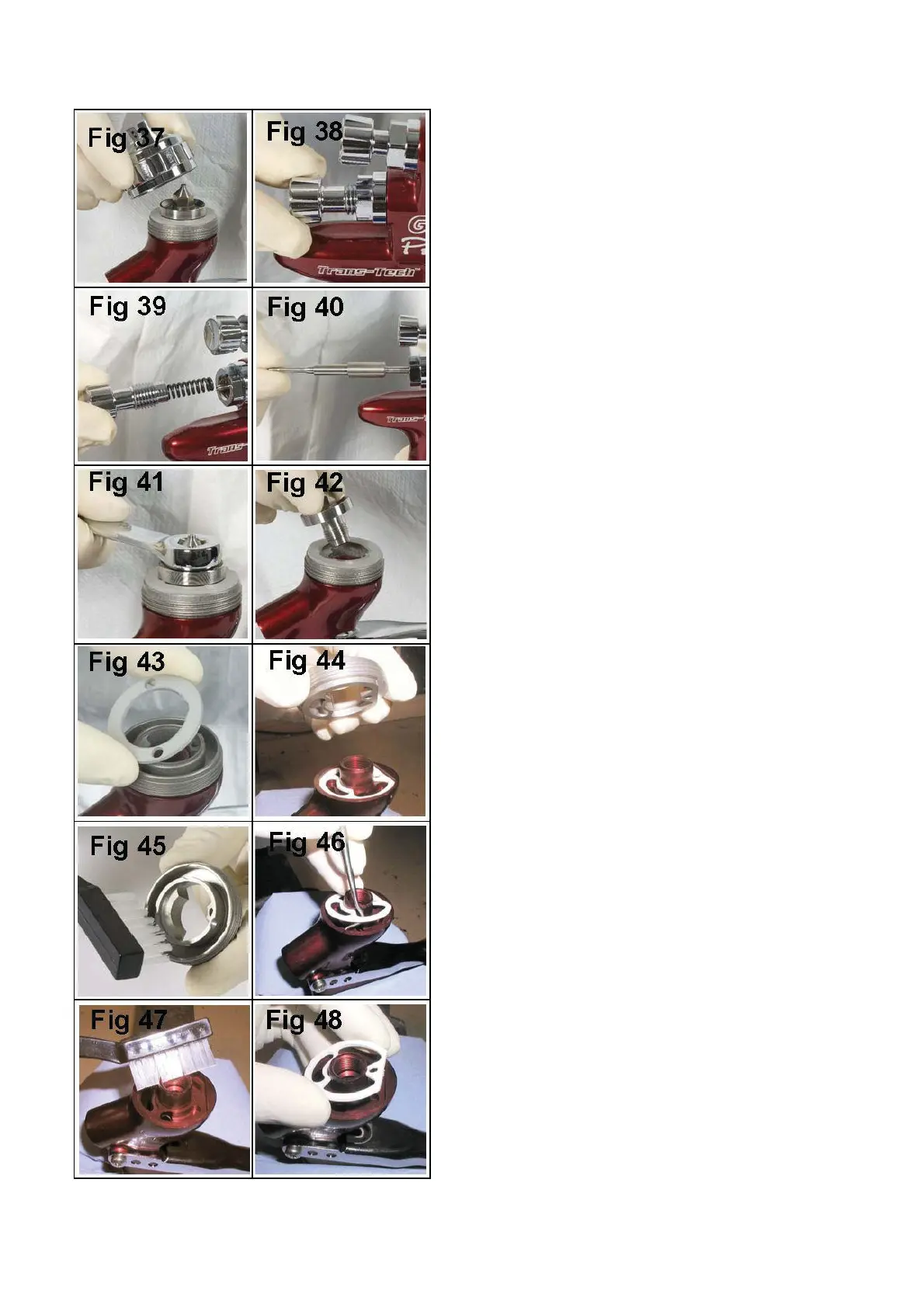

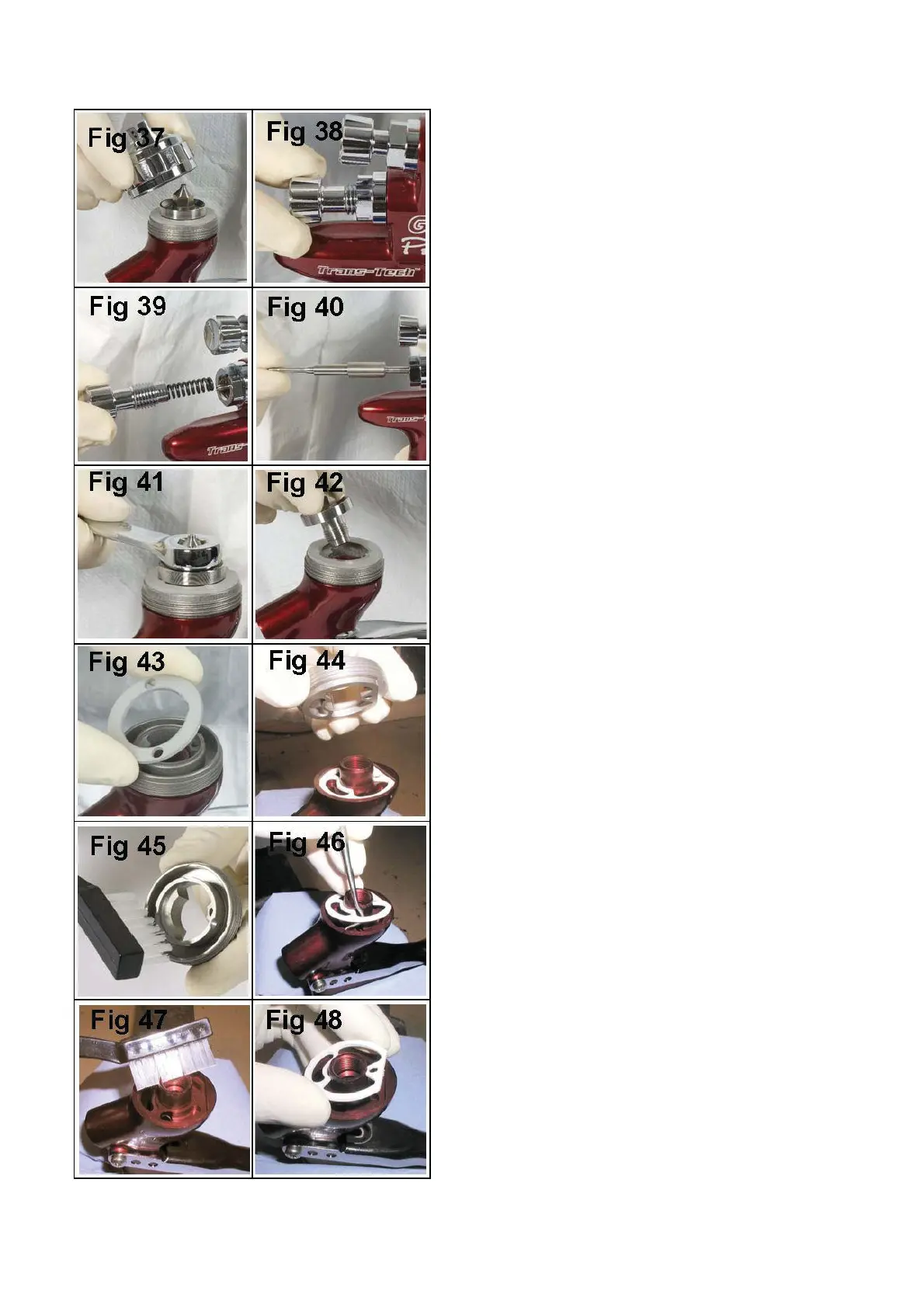

1. Remove air cap and retaining ring. (See fig 37)

2. Remove fluid adjusting knob, spring, and spring pad.

(See figs 38 & 39)

3. Remove fluid needle from gun body. (See fig 40)

4. Remove fluid nozzle using SN-28 (10 mm) ring

Spanner, and then remove the Front Plate. (See figs

41, 42 & 43)

5. Remove Spray Head. (See fig 44).

6. Clean Spray Head with a soft brush (See fig 45).

7. Remove Spray Head seal using a small screwdriver or

pick. (See fig 46)

8. Clean front of gun if required, using a soft brush, as

well as the Spray Head, fluid nozzle, air cap, and

retaining ring. (See fig 47)

9. Place a new Spray Head Seal onto the front of the gun,

making sure the flat on the seal is aligned with the flat in

the gun. (See fig 48).

10. Fit the Front Plate onto the Spray Head, fit Spray Head to

the Gunbody, ensuring the flat on the underside of the

Spray Head locates with the flat in the Gun Body. Fit Fluid

Nozzle, Air Cap, and Retaining Ring. Torque the Fluid

Nozzle to 18–20 nm. Don’t over torque the fluid nozzle.

(See figs 44, 43, 42, 41 and 37)

11. Insert Fluid Needle all the way into the Gun Body,

seating in the Fluid Nozzle. (See fig 40)

12. Reassemble Needle Spring, Spring Pad, and Fluid

adjusting Knob. (See figs 39 & 38)

13. Trigger gun fully and screw in Fluid Adjusting Knob until

it stops. Back it off 1/2 turn and gun will have full needle

travel.

14. Trigger gun several times to verify correct operation.

Loading...

Loading...