LT-1929

12

TROUBLESHOOTING

NOTE–After completing any repairs, ensure Hour Meter on the right cover is connected to the DC wire harness and the Control

Panel ribbon connector is connected to the main PC Board prior to installing the left cover. Also ensure magnet has been removed if

used to troubleshoot.

NOTE–Before returning to service, the iFill Station should undergo a Performance Test to ensure it is operating properly (refer to

page 9).

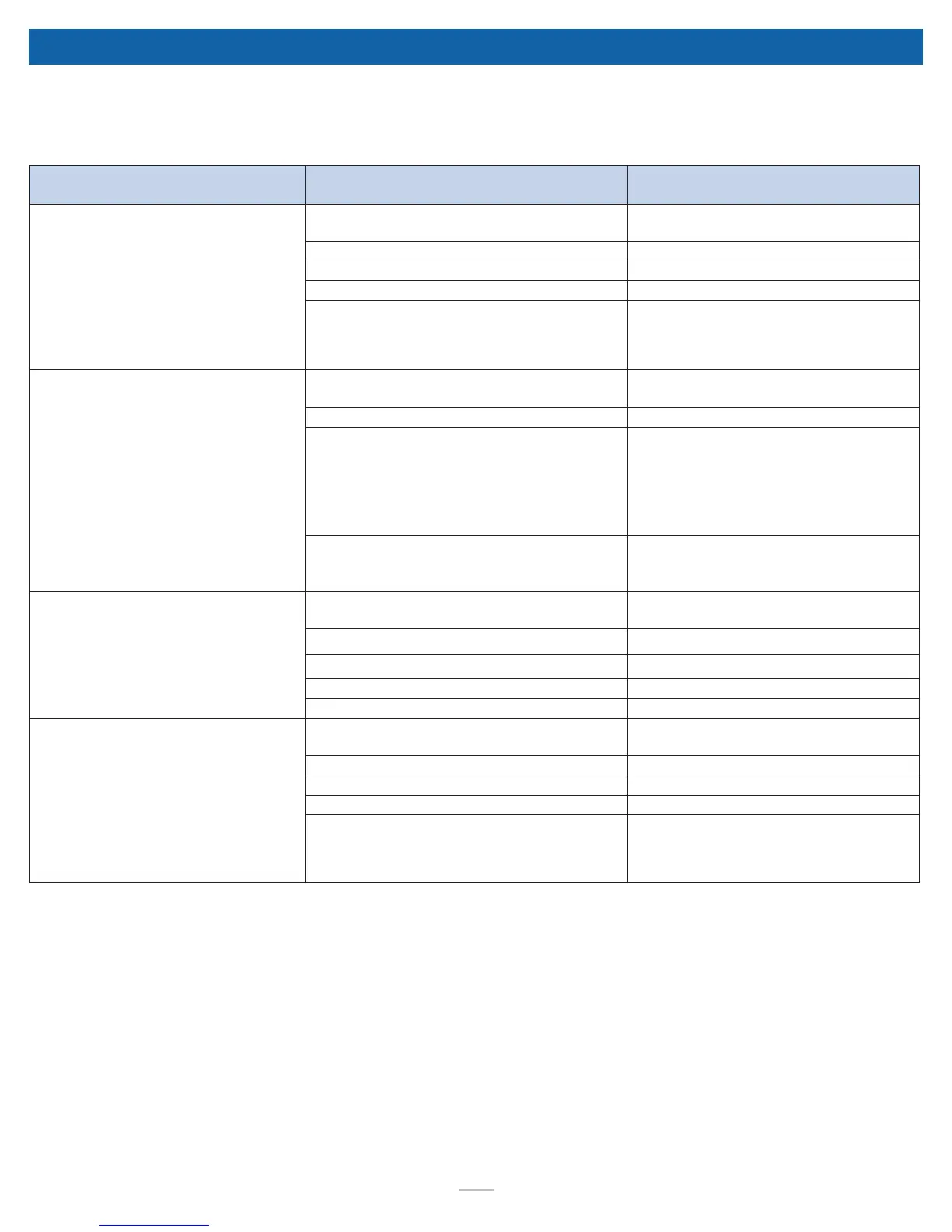

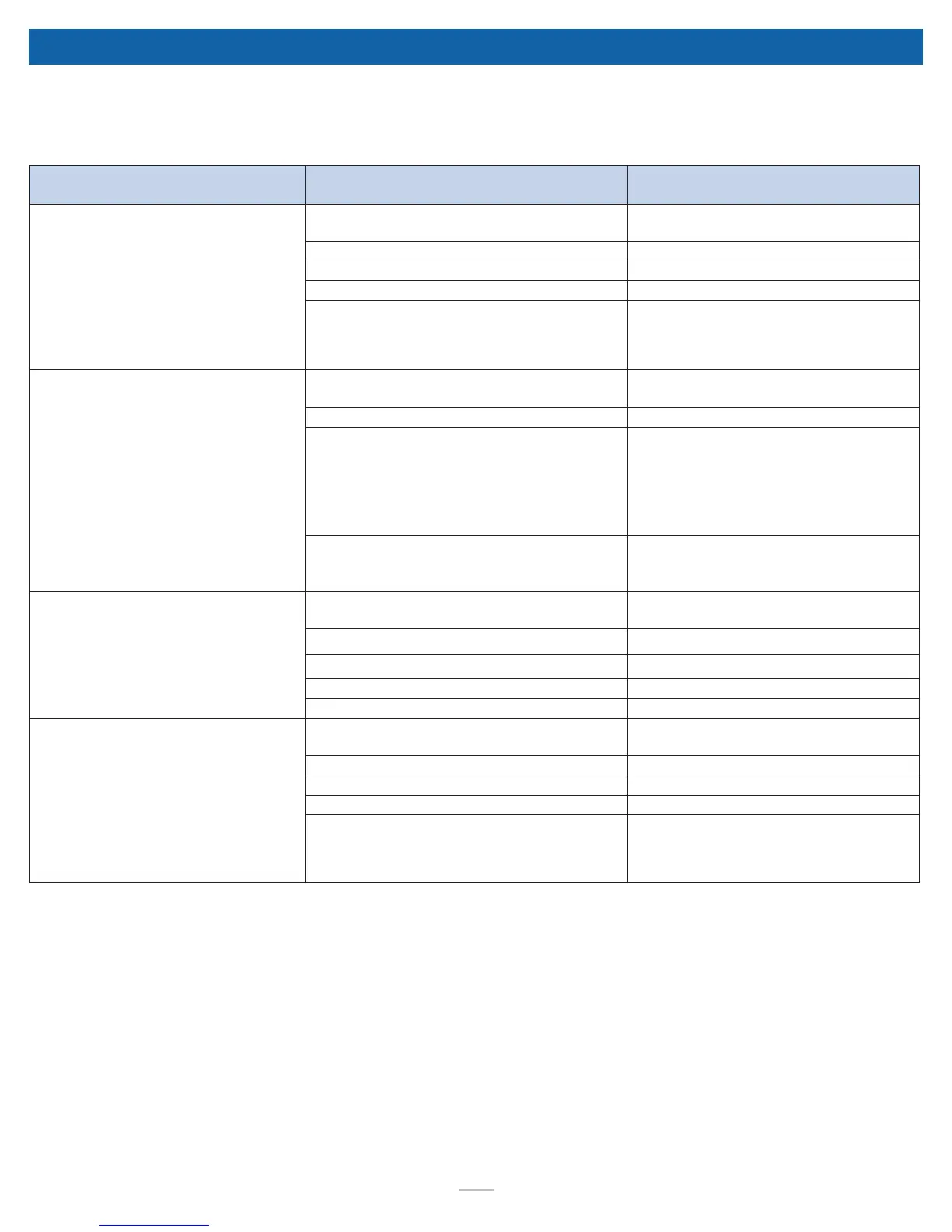

TROUBLESHOOTING CHART B

Problems during fill cycle

(After unit running longer than approximately 4 minutes run time.)

Symptom

(during ll - after 4 minutes) Possible Cause Remedy

(A) The unit runs for 11 minutes after

start up then shuts off and alarms.

- Note that if the OSD does not see

91% oxygen after 11 consecutive

minutes the unit shuts off and

alarms.

- (If unit is in warm up mode the

three-way click sound will not be

heard every 24 seconds)

1. System air leak (compressor tubing, sieve

beds, accumulator tank, bacteria lter, etc.).

1. Repair or replace as necessary.

2. Faulty OSD on main PC board. 2. Replace main PC board.

3. Faulty sieve beds. 3. Replace sieve beds.

4. Faulty rotary valve. 4. Replace rotary valve.

5. Faulty compressor (low output ow). 5. Replace compressor.

(B) The unit shuts off and alarms prior

to lling a cylinder to 2,000 PSIG.

- Verify unit did not go back into

warm up mode for 11 consecutive

minutes per (A) above.

- The intensier drive piston travels

slowly and or does not travel fully

as veried visually with magnet.

- (Similar to start up

Troubleshooting A, #9 but this

usually occurs during cylinder

lling at higher pressures)

1. System air leak (compressor or four-way

valve tubing connections)

1. Repair or replace as necessary.

2. Faulty four-way valve (internal leakage) 2. Replace four-way valve.

3. Faulty compressor (verify faulty compressor

by using duck bill pliers to pinch the tubing

closed that comes from the compressor just

below the small DC power supply board. If

the compressor PR valve does not pop off

immediately, replace the compressor)

3. Replace compressor.

4. Faulty intensier. 4. Replace intensier.

(C) The unit shuts off and alarms prior

to lling a cylinder to 2,000 PSIG.

- The intensier drive piston travels

to the end and sits there until unit

alarms. (See Troubleshooting A,

#7)

1. DC wire harness not properly connected to

Intensier hall effect board.

1. Reconnect DC wire harness to

intensier hall effect board.

2. Faulty or intermittent four-way valve. 2. Replace four-way valve.

3. Faulty main PC board. 3. Replace main PC board.

4. Faulty DC wire harness. 4. Replace DC wire harness.

5. Faulty intensier. 5. Replace intensier.

(D) The unit runs for an extended

period of time and does not ll a

cylinder or complete a normal ll

cycle. The unit does not alarm.

- Verify unit does not constantly go

in and out of warm up mode for

several minutes at a time, but not

for 11 consecutive minutes as in

(A) above.

1. System air leak (compressor tubing, sieve

beds, accumulator tank, bacteria lter, etc.).

1. Repair or replace as necessary.

2. Faulty sieve beds. 2. Replace sieve beds.

3. Faulty rotary valve. 3. Replace rotary valve.

4. Faulty compressor (low output ow). 4. Replace compressor.

5. Faulty intensier. 5. Replace intensier.

Loading...

Loading...