Page 2 SB-2-240-C

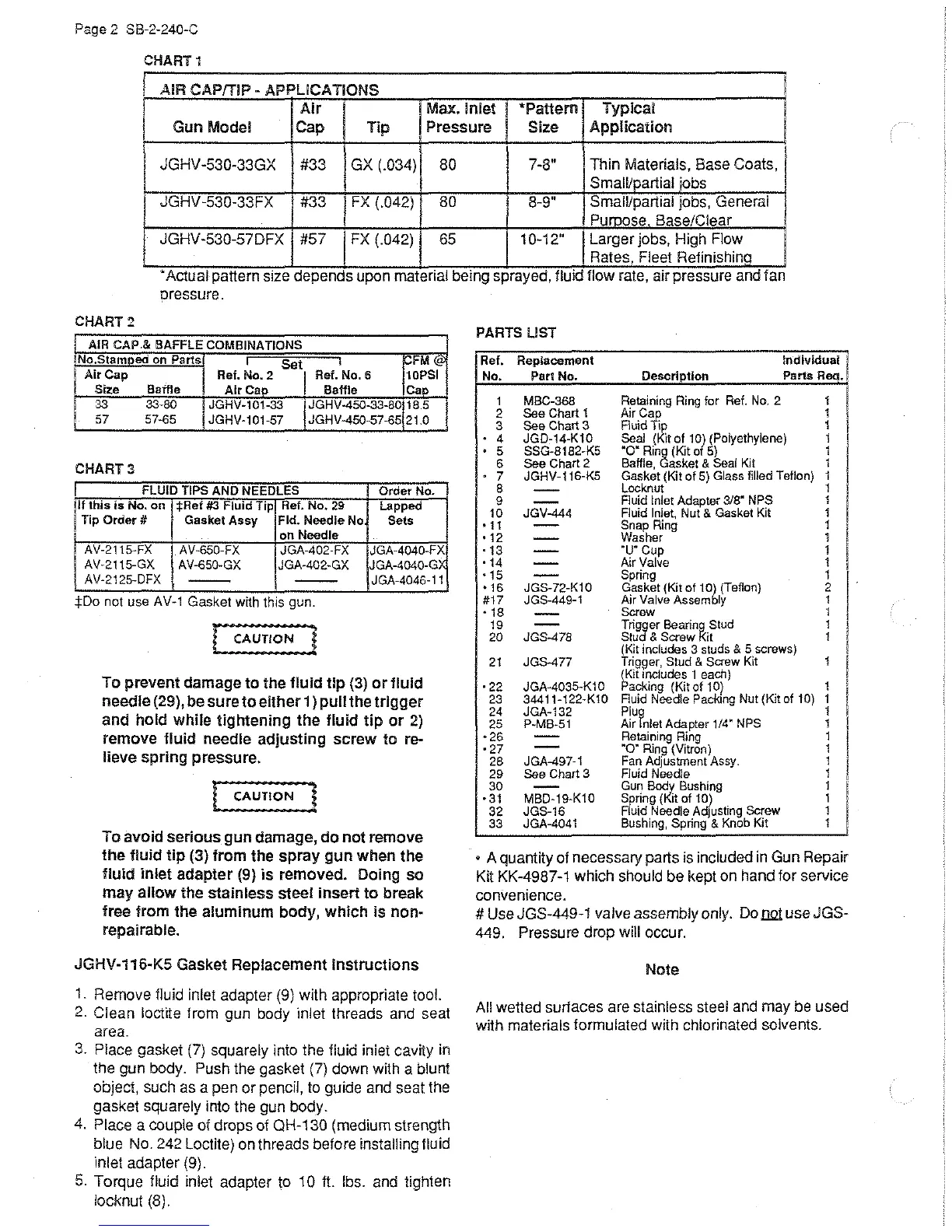

CHART1

1 AIR CAP/TIP APPLICATIONS

-

I

Air

I

Max. Inlet

I

*Pattern I Typical

Gun Model Cap Tip

Pressure

Size

Application

JGHV -530-33GX #33

GX

(.034) 80 7-8" Thin Materials, Base Coats, I

Small/partial

jobs

JGHV -530-33FX

I #33

I

FX

(.042)

80

I

8-9" SmaiVpartial jobs, General

Puroose Base/Clear

JGHV-530-57DFX #57

I

FX

(.042)

65

1 0-12"

Larger jobs, High Flow

Rates. Fleet Refinishino

.

Actual pattern

SIZe

depends upon matenal bemg sprayed,

flUid

flow rate,

a1r

pressure

and

fan

oressure.

CHART2

AIR CAP.& BAFFLE COMBINATIONS

No.Stamped

on Parts

I

Set

I

Air Cap

Ref.

No.2

I

Ref.

No.6

c;FM_';9'

10PSI

Size Baffle

Air

Cap Baffle Cap

33

33-80

JGHV-t01-33

I :GHV-450-33-80

18.5

57 57-65

JGHV-101-57 JGHV-450-57-65

21.0

CHART3

I FLUID TIPS AND NEEDLES

If this

is

No.

on

*Ret

#3

Fluid

Tip

Ref. No. 29

Tip

Order#

Gasket

Assy

Fld. Needle No

on

Needle

AV-2115-FX AV-650-FX JGA-402-FX

AV-2115-GX

AV-650-GX

JGA-402-GX

AV-2125-DFX

--

--

:j:Do

not

use

AV-1

Gasket

w1th

this

gun.

!

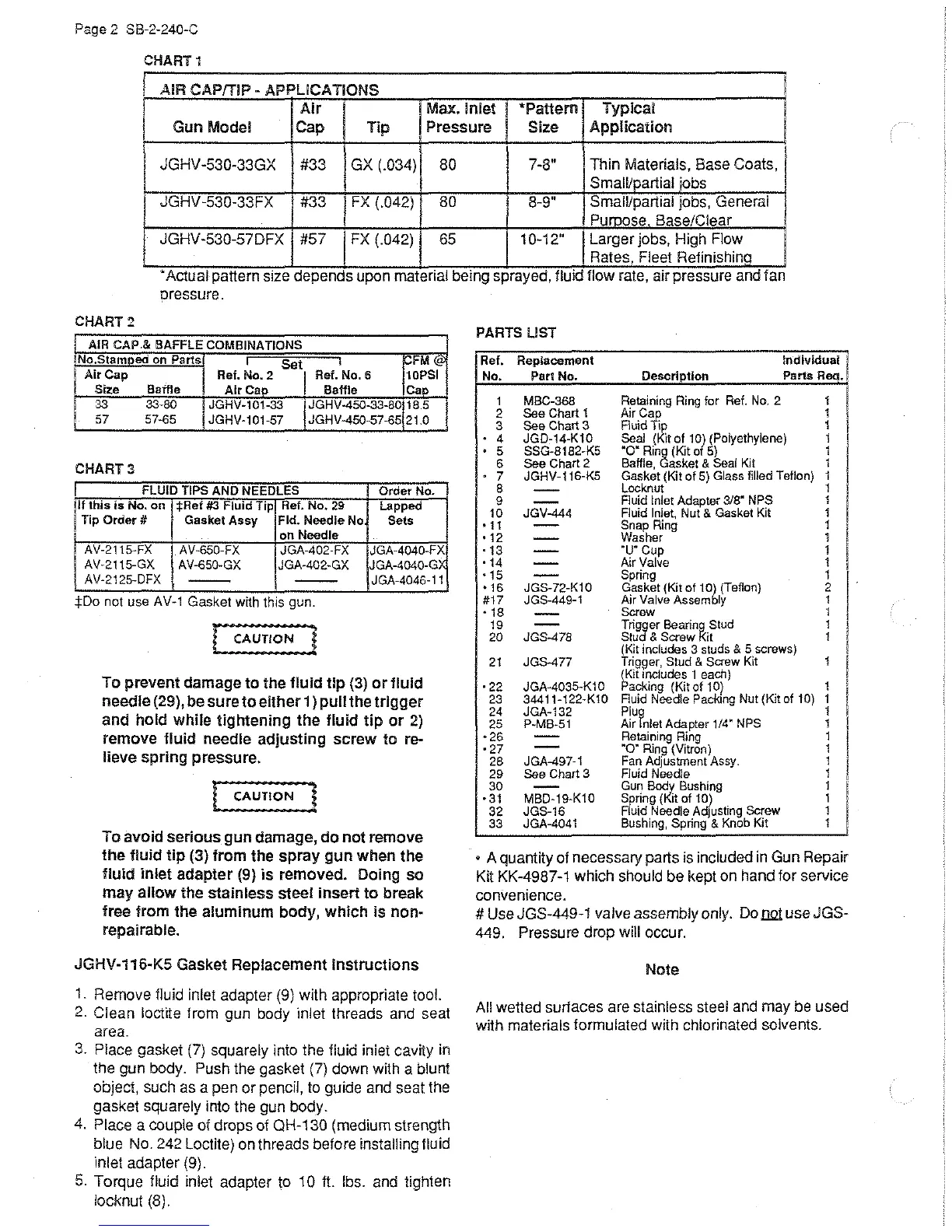

CAUTION

J

Order

No

Lapped

Sets

JGA-4040-FX

JGA-4040-GX

JGA-4046-t1

To prevent damage

to

the

fluid

tip

(3)

or

fluid

needle (29), be

sure

to

either

1)

pull

the

trigger

and

hold

while

tightening

the

fluid

lip

or

2)

remove

fluid

needle

adjusting

screw

to

re-

lieve

spring

pressure.

l

CAUTION

]

To avoid

serious

gun

damage,

do

not

remove

the

fluid

tip

(3) from the

spray

gun

when

the

fluid

inlet

adapter

(9)

is

removed. Doing

so

may

allow

the

stainless

steel

insert

to

break

tree

from

the

aluminum

body,

which

is

non-

repairable.

JGHV-116-KS Gasket Replacement

Instructions

1.

Remove fluid inlet adapter

(9)

with appropriate tool.

2. Clean loctite from gun body inlet threads and seat

area.

3.

Place gasket

(7)

squarely into the fluid inlet cavity in

the gun body. Push the gasket

(7)

down with a blunt

object, such

as

a pen or pencil,

to

guide and seat the

gasket squarely into the gun body.

4.

Place a couple of drops of QH-130 (medium strength

blue No. 242 Loctite)

on

threads before installing fluid

inlet adapter (9).

5.

Torque fluid inlet adapter to 10 II. lbs.

and

tighten

locknut (8).

PARTS UST

Ref.

Replacement

Individual

No. Part No. Descriotion

Parts ReQ.

t

MBC-368

Retaining

Ring

for

Ref.

No.

2 t

2

See Chart 1

Air

c¥;

1

3 See

Chart3

Fluid ip

1

4

JGD-14-K10

Seal (Kit of 10( (Polyethylene)

1

5

SSG-8182-K5

·o· Ring (l<it o 5)

1

6

See Chart 2 Baffle, asket & Seal Kit

1

7

JGHV-t16-K5 Gasket (Kit

of

5) Glass filled Teflon) 1

B

-

Locknut

1

9

-

Fluid Inlet Adapter 3/8" NPS

1

10 JGV-444

Fluid Inlet, Nut & Gasket

Kit

1

•1t

-

Snap Ring 1

•12

-

Washer

1

·13

-

·u·

Cup 1

•14

-

Air

Valve

t

•15

-

Spring

1

•t6

JGS-72-K10 Gasket (Kit of

tO~

(Teflon)

2

#t7

JGS-449-1

Air

Valve

Assem

ly

1

•18

-

Screw

1

19

-

T

rig3er

BearinR-

Stud

1

I

20 JGS-478

Stu

& Screw

it

1

(Kit

includes

3

studs

& 5

screws}

21

JGS-477 Trigger, Stud & Screw Kit

1

I

~Kit

mcludes

1

each)

• 22

JGA-4035-KtO acking (Kit of 10) 1

I

23

344tt-122-K10

Fluid Needle Packing Nut (Kit of

tO)

t

24 JGA-132

Plu~

t

I

25

P-MB-St

Air nlet Adapter 1/4" NPS 1

I

•26

-

Retaining

Ring

1

• 27

-

·o·

Ring

(Vitron)

1

28

JGA-497-1

Fan

Adjustment

Assy.

1

I

29

See

Chart 3 Fluid Needle

t

I

30

-

Gun

Bod~

Bushing

t

·31

MBD-19-K10 Spring ( it of 10)

t

32

JGS-16

Fluid

Needle

Adjusting

Screw

1

33

JGA-4041

Bushing,

Spring

&

Knob

Kit

1

• A quantny of necessary parts

is

included

in

Gun Repair

Ktt

KK-4987-1 which should be kept on hand for service

convenience.

# Use JGS-449-1 valve assembly only.

Do

LlQt

use JGS-

449. Pressure drop will occur.

Note

All

wetted suriaces are stainless steel

and

may

be

used

with materials

formulated with chlorinated solvents.

Loading...

Loading...