10

English

Cleaning

WARNING: Blow dirt and dust out of all air vents with clean, dry air

at least once a week. To minimize the risk of eye injury, always wear

ANSI Z87.1 approved eye protection when performing this.

WARNING: Never use solvents or other harsh chemicals for

cleaning the non-metallic parts of the tool. These chemicals may

weaken the plastic materials used in these parts. Use a cloth

dampened only with water and mild soap. Never let any liquid get

inside the tool; never immerse any part of the tool into a liquid.

Lubrication

Your tool was properly lubricated before leaving the factory. In from

two to six months, depending upon use, take or send your tool to

an authorized service center for a complete cleaning, inspection

and lubrication. Tools used constantly on production jobs will need

relubrication more often. Also, tools “out of service” for long periods

should be relubricated before being put back to work.

Accessories

WARNING: Since accessories, other than those offered by

D

EWALT, have not been tested with this product, use of such

accessories with this tool could be hazardous. To reduce the risk of

injury, only D

EWALT recommended accessories should be used with

this product.

Recommended accessories for use with your tool are available at

extra cost from your local dealer or authorized service center. If you

need assistance in locating any accessory, please contact D

EWALT

Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286, call

1-800-4-D

EWALT (1-800-433-9258) or visit our website: www.dewalt.

com.

Chipping and Chiselling (D25013, D25023)

1. To switch from hammer drilling to chiselling, first insert the SDS

Plus

®

chisel and check if it is properly locked.

2. When switching from hammer drilling mode to chiselling mode,

turn the chisel to the desired position. If you find resistance during

mode change, turn the chisel slightly to engage the spindle lock.

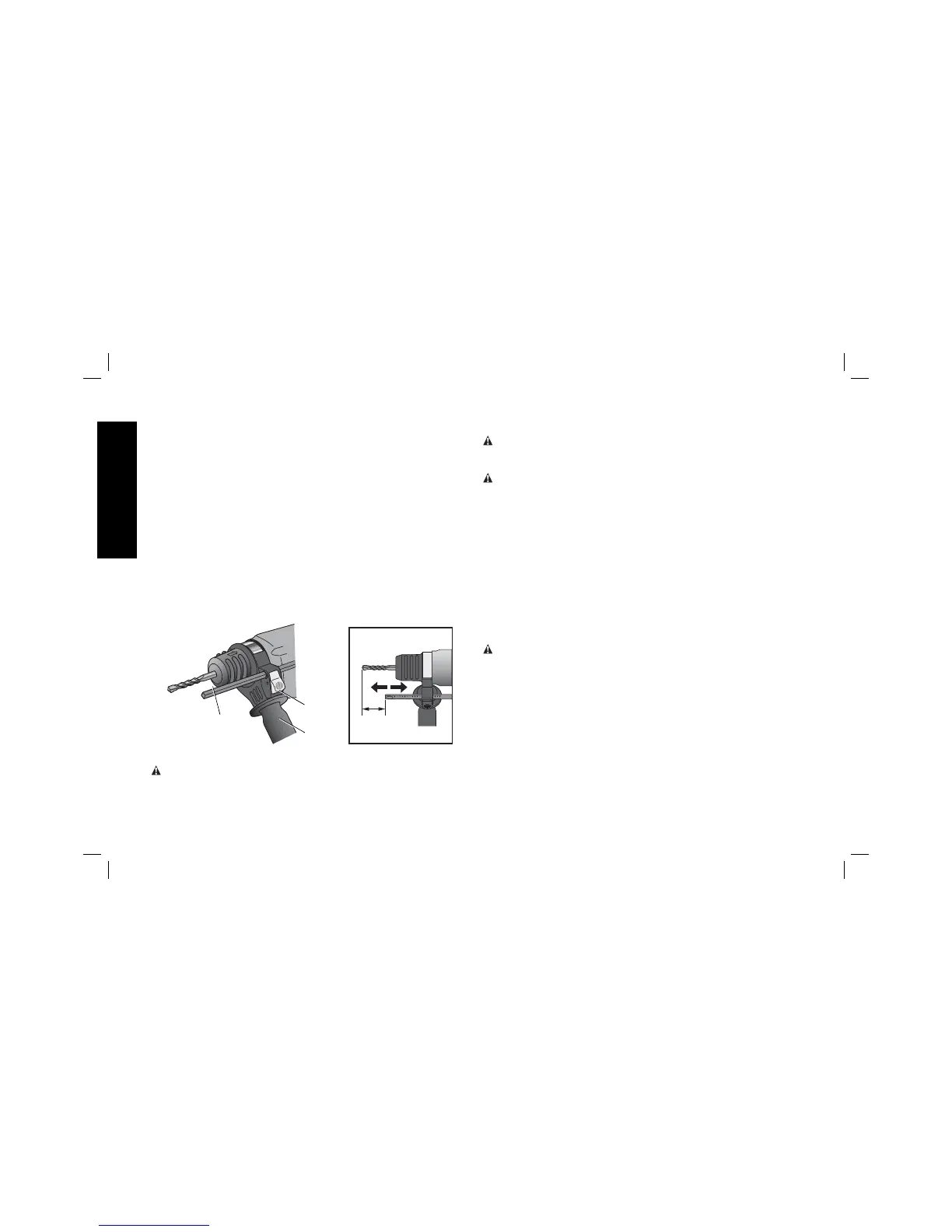

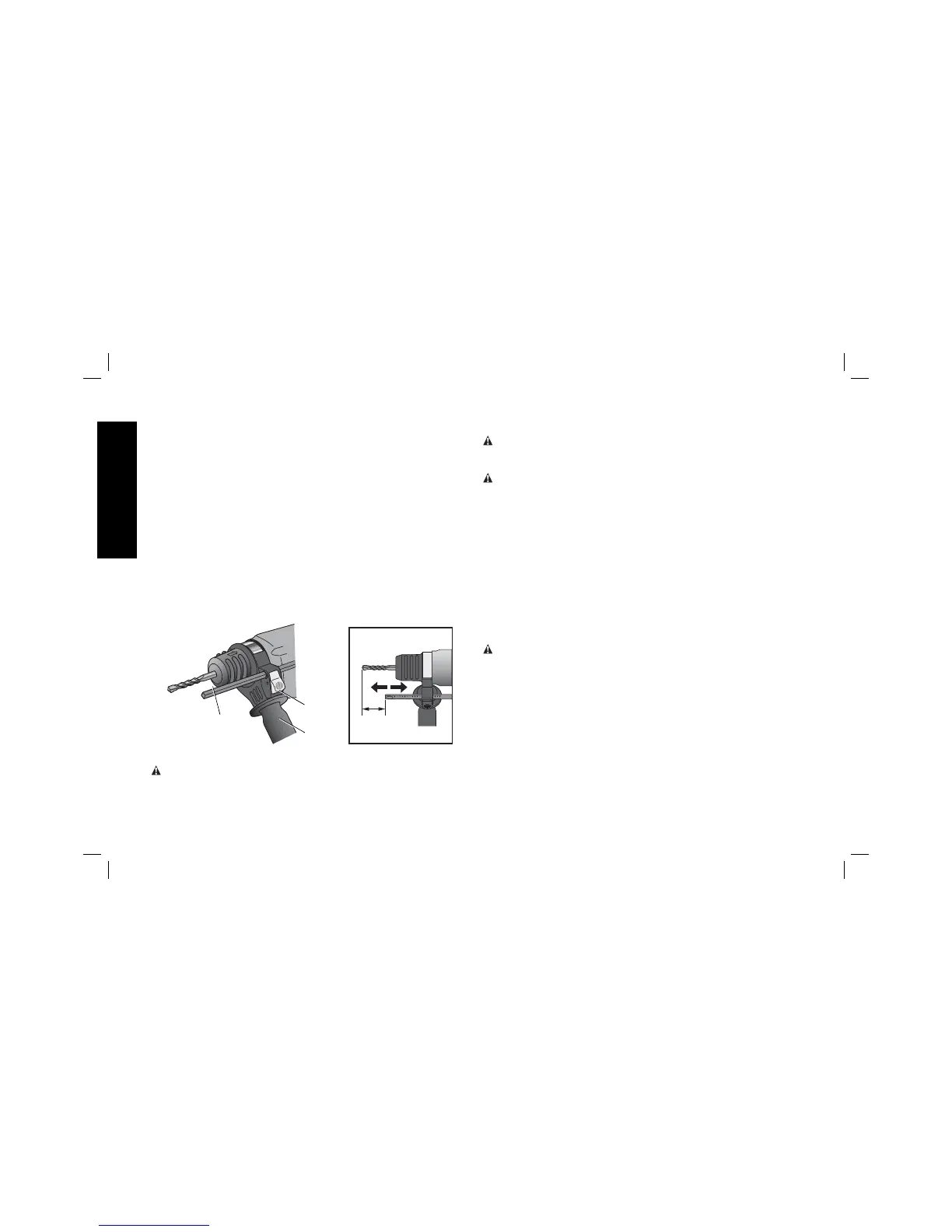

Depth Rod (Fig. 5)

TO ADJUST THE DEPTH ROD

1. Push in and hold the depth rod release button (J) on the side

handle.

2. Move the depth rod (D) so the distance between the end of the

rod and the end of the bit equals the desired drilling depth.

3. Release the button to lock rod into position. When drilling with the

depth rod, stop when end of rod reaches surface of material.

FIG. 5

J

D

C

MAINTENANCE

WARNING: To reduce the risk of injury, turn unit off

and disconnect it from power source before installing and

removing accessories, before adjusting or when making

repairs. An accidental start-up can cause injury.

Loading...

Loading...