ENGLISH

20

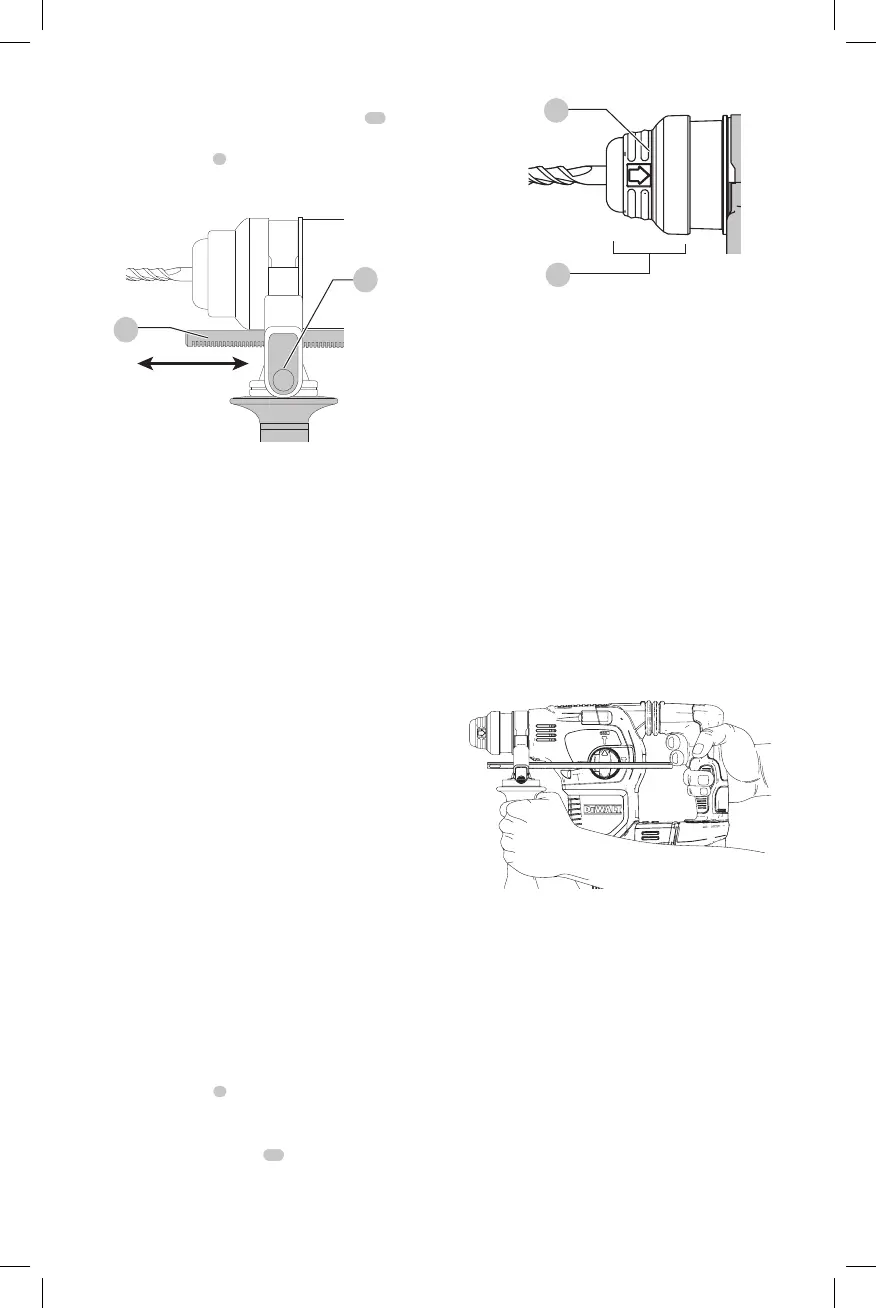

To Adjust the Depth Rod (Fig. C)

1. Push in and hold the depth rod release button

10

on

the sidehandle.

2. Move the depth rod

9

so the distance between the

end of the rod and the end of the bit equals the desired

drillingdepth.

Fig. C

9

10

3. Release the button to lock rod into position. When

drilling with the depth rod, stop when end of rod

reaches surface ofmaterial.

Bit and Bit Holder

WARNING: Burn Hazard. ALWAYS wear gloves when

changing bits. Accessible metal parts on the tool and

bits may get extremely hot during operation. Small

bits of broken material may damage barehands.

WARNING: Do not attempt to tighten or loosen drill

bits (or any other accessory) by gripping the front part

of the chuck and turning the tool on. Damage to the

chuck and personal injury mayoccur.

The rotary hammer can be fitted with various chisel bits

depending on the desired application. Use sharp drill

bitsonly.

Bit Reccomendations

• For wood, use twist bits, spade bits, power auger bits or

holesaws.

• For metal, use high-speed steel twist drill bits or

holesaws. Use a cutting lubricant when drilling metals.

The exceptions are cast iron and brass which should be

drilleddry.

• For masonry, such as brick, cement, cinder block, etc.,

use carbide-tipped bits rated for percussiondrilling.

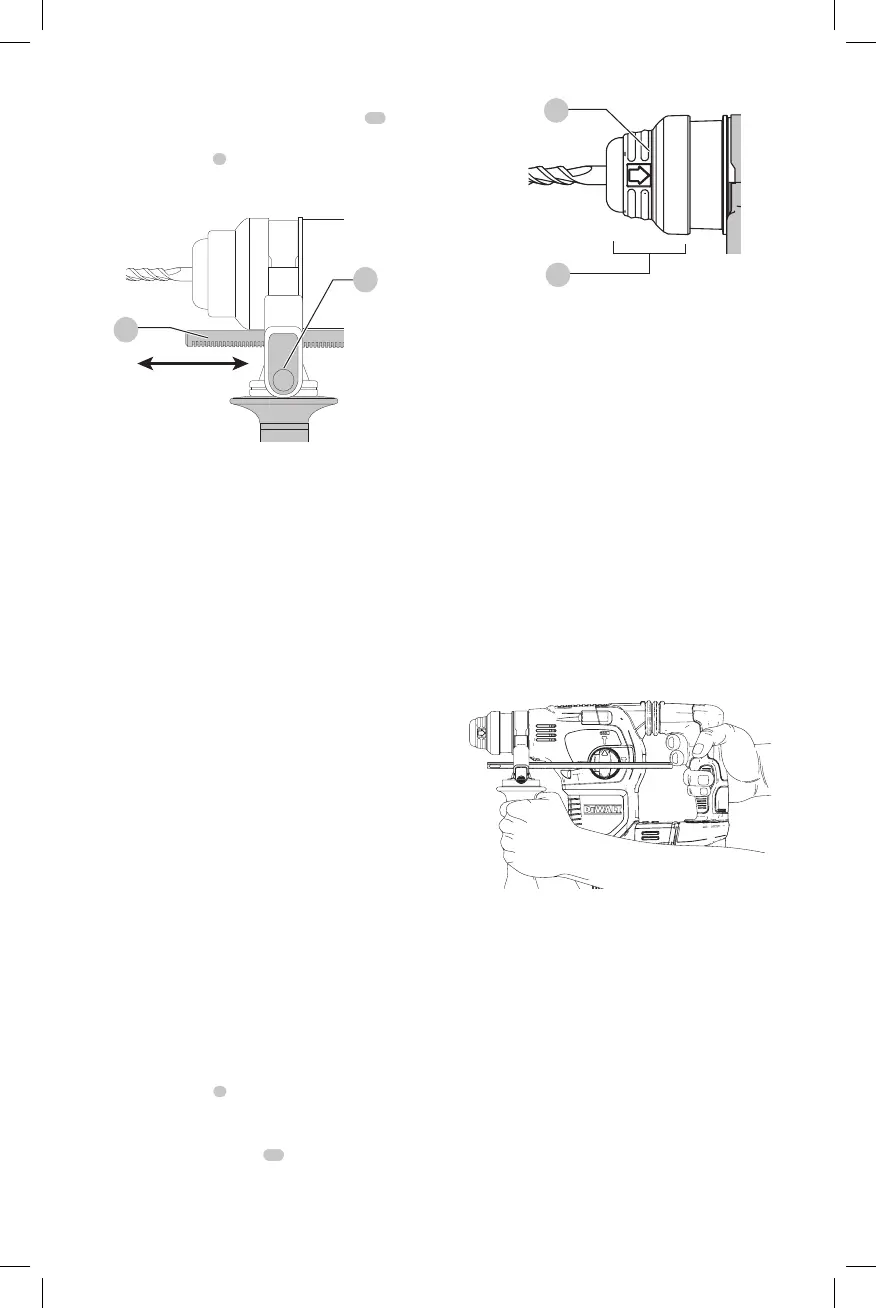

SDS Plus Bit Holder (Fig. D)

NOTE: Special adapters are needed to use the SDS

Plus bit holder with straight shank bits and hexagonal

screwdriverbits.

To insert a drill bit or other accessory:

1. Insert the shank of the bit about 3/4" (19mm) into

SDSPlus tool holder

7

.

2. Push and rotate bit until it locks in place. The bit will be

securelyheld.

3. To release bit, pull the sleeve

13

back and remove

thebit.

Fig. D

7

13

To remove the bit, pull back the locking sleeve and pull the

bitout.

OPERATION

WARNING: Always observe the safety instructions

and applicableregulations.

WARNING: To reduce the risk of serious personal

injury, turn unit off and disconnect it from

power source before making any adjustments or

removing/installing attachments or accessories.

An accidental start-up can causeinjury.

Proper Hand Position (Fig. E)

WARNING: To reduce the risk of serious personal injury,

ALWAYS use proper hand position as shown.

WARNING: To reduce the risk of serious personal

injury, ALWAYS hold securely in anticipation of a

suddenreaction.

Proper hand position requires one hand on the mounted

side handle, with the other hand on the mainhandle.

Fig. E

SHOCKS Active Vibration Control®

System

For best vibration control, hold the tool as described in

Proper Hand Position and apply just enough pressure so

the damping device on the main handle is approximately

mid stroke. The hammer only needs enough pressure to

engage the active vibration control. Applying too much

pressure will not make the tool actuate faster and active

vibration control will notengage.

Overload Clutch

In case of jamming of a drill bit, the drive to the drill spindle

is interrupted by the overload clutch. Due to the resulting

forces, always hold the tool with both hands and take a

firmstance. After the overload, release and depress the

trigger to re-engagedrive.

Loading...

Loading...