ENGLISH

25

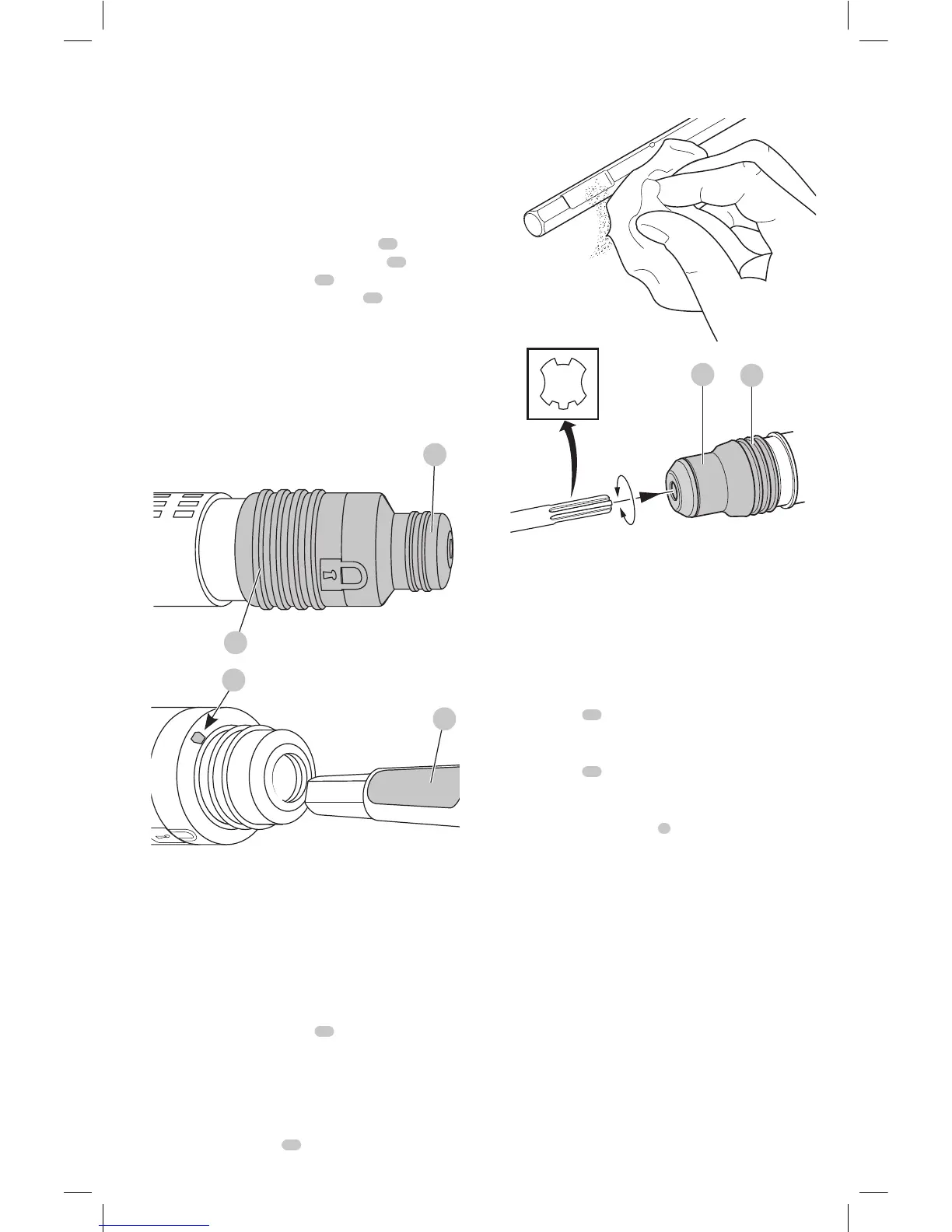

Inserting and Removing Spline Drive

Accessories (Fig. C)

D25851

WARNING: To reduce the risk of serious personal

injury, turn tool off and disconnect tool from

power source before making any adjustments or

removing/installing attachments oraccessories.

1. Insert the bit shank into the tool holder

13

as far as

it will go. The groove on the chisel shank

17

must

be aligned with the symbol

15

on the toolholder. If

inserted correctly, the locking sleeve

16

moves back to

the end position and shows a closed locksymbol.

2. Pull on the bit to be sure that it is properlylocked.

3. If the chisel groove is not aligned with the symbol, or

is not inserted to the complete depth the lock symbol

remainsopen.

4. To remove the bit, pull back the locking sleeve and pull

the bitout.

Fig. C

13

17

15

16

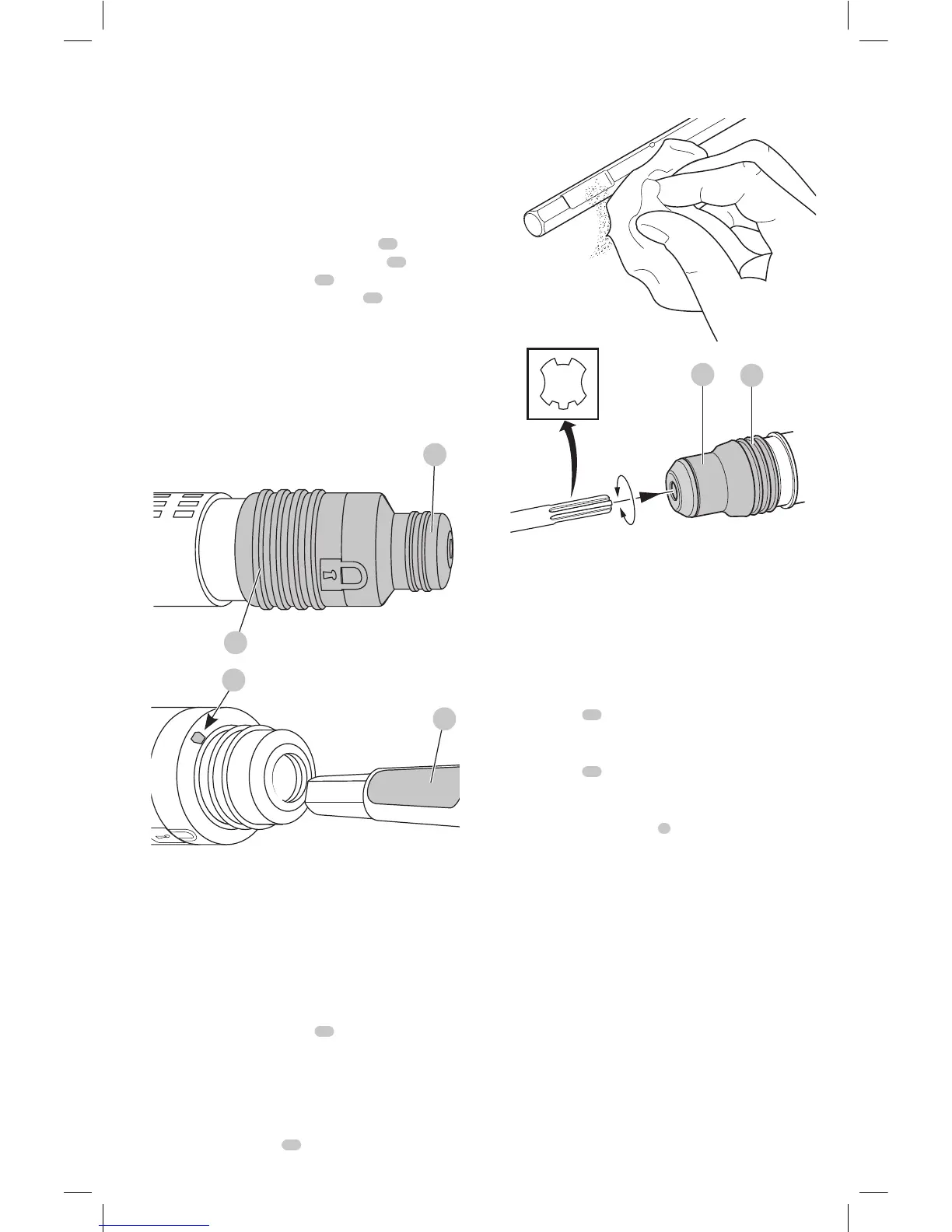

Inserting and Removing SDS Max®

Accessories (Fig. D)

D25501, D25602, D25820, D25831

WARNING: To reduce the risk of serious personal

injury, turn tool off and disconnect tool from

power source before making any adjustments or

removing/installing attachments oraccessories.

1. Pull back the locking sleeve

16

and insert the bit shank.

The bit shank must beclean.

2. Turn the bit slightly until the sleeve snaps back

intoposition.

3. Ensure the bit is properlyengaged.

NOTE: The bit needs to move several centimeters in and

out of the tool holder

13

when properlyengaged.

4. To remove the bit, pull back the locking sleeve and pull

the bitout.

Fig. D

13

16

Complete Torque Control (Fig. E)

D25602

NOTICE: Always turn the tool off before changing

torque control settings or damage to tool mayresult.

The Complete Torque Control (CTC) feature of this tool is

designed to provide additional control with a two-stage

clutchmechanism.

Clutch Setting 1

14

is designed for most hammerdrilling

applications and is designed to easily clutch out when the

drill bit encounters re-bar or other foreignsubstances.

Clutch Setting 2

11

is designed for higher torque

applications such as core-bits and deep hole hammerdrilling

and is designed to clutch out at a higher torquethreshold.

Move the torque control lever

8

to setting 1 or 2 as needed

forapplication.

NOTE: Allow the motor housing to rotate a little while

changingtorque.

Each time the tool is plugged in, it will automatically default

to clutch setting 1, the most sensitivesetting.

Loading...

Loading...