ENGLISH

26

14

11

8

7

9

10

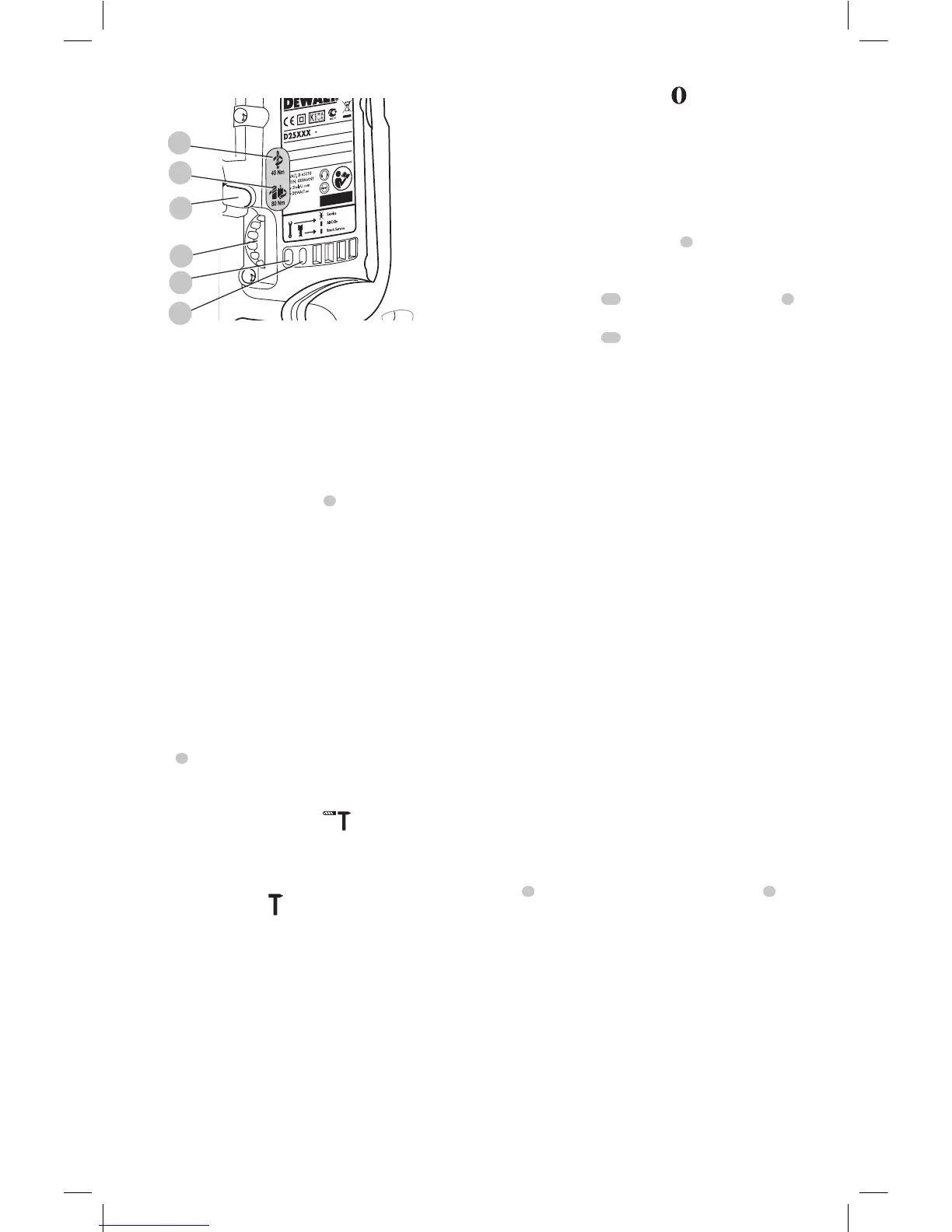

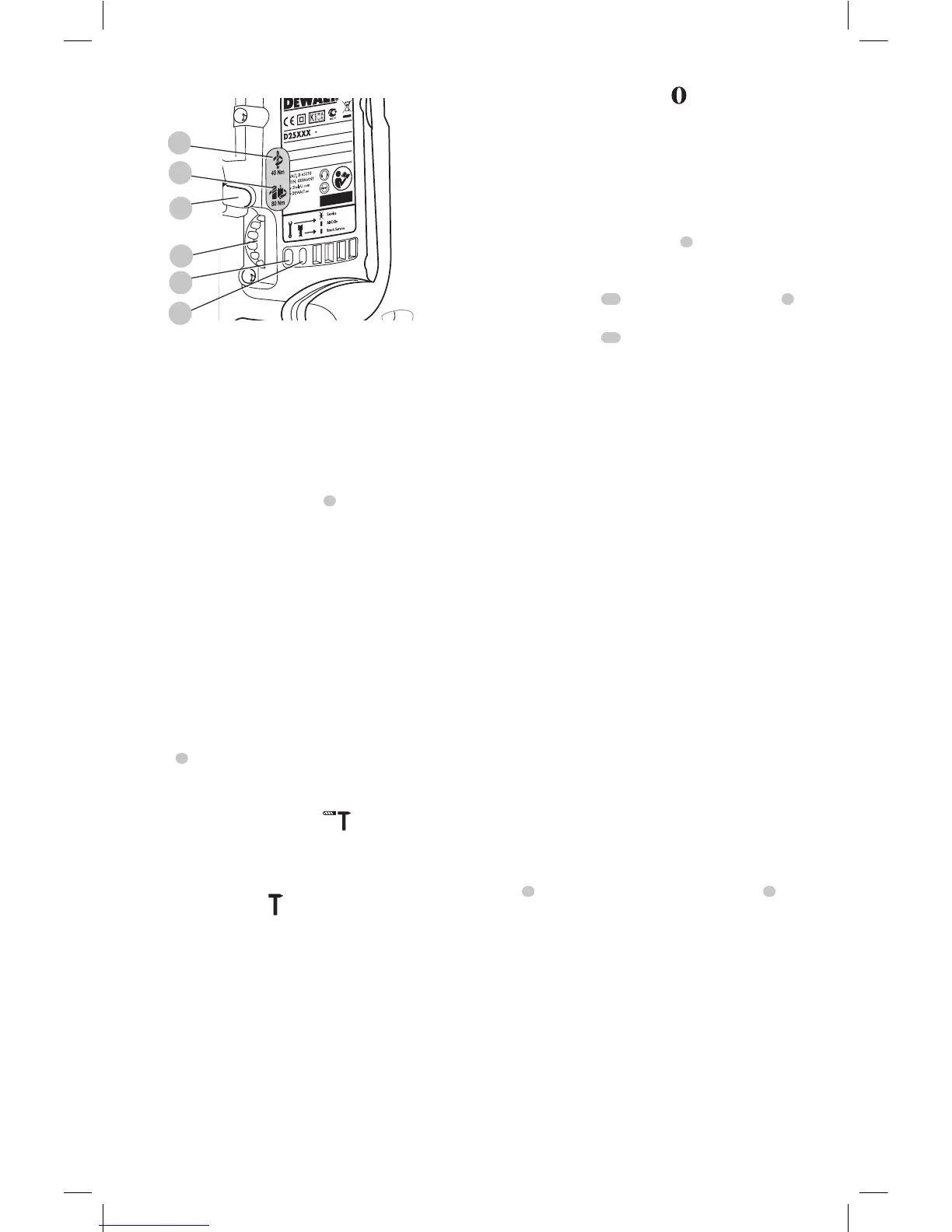

Fig. E

Electronic Speed and Impact Control

(Fig. E)

D25602, D25831, D25851

The electronic speed and impact control allows the

use of smaller drill bits without the risk of bit breakage,

hammerdrilling into light and brittle materials without

shattering and optimal tool control for precisechipping.

To set the control dial, turn the dial

7

to the desired level.

The higher the number, the greater the speed and impact

energy. Dial settings make the tool extremely adaptable for

many different appli cations. The required setting depends

on the bit size and hardness of material beingdrilled.

Mode Selector (Fig. A)

CAUTION: Never change the mode while the unit

isrunning.

CAUTION: Do not change to hammerdrill mode with

chisel bit in tool holder. Personal injury and damage

to tool mayresult.

The D25501, D25601, D25602 uses two operating modes.

To select the required operating mode, rotate the mode

selector

6

until the arrow points to the hammerdrilling

or the chipping icon. The D25820, D25831 uses only the

chippingmode.

Hammerdrilling Mode ( )

The tool simultaneously rotates and impacts the

work. This mode is appropriate for all concrete and

masonryoperations.

Chipping Mode ( )

The spindle lock is engaged during chipping mode

so the tool impacts the work without rotating. This

mode is appropriate for light chipping, chiseling and

demolitionapplications.

NOTE: In chipping mode, the hammerdrill can also be used

as a lever to free a jammed drillbit.

Chisel Bit Adjustment ( )

Turn the mode selector to one of the chisel bit adjustment

icons to adjust the chisel to the desired position. There are

18 possible positions to set the angle of the chisel. After

finding the desired position, slightly maneuver the chisel bit

back and forth to ensure the chisel is properlyengaged.

Power Indicator Lights (Fig. A, E)

The yellow brushwear indicator LED

9

lights up when the

carbon brushes are nearly worn out indicating that the tool

needs servicing within the next 8 hours ofuse.

The red indicator LED

10

lights up if the lock-on slider

2

is

used in any mode except the chippingmode.

The red indicator LED

10

flashes if there is a fault with the

tool or if the brushes are completely worn.

OPERATION

WARNING: Always observe the safety instructions

and applicableregulations.

WARNING: To reduce the risk of serious personal

injury, turn unit off and disconnect it from

power source before making any adjustments or

removing/installing attachments or accessories.

An accidental start-up can causeinjury.

WARNING: To reduce the risk of personal injury,

ALWAYS ensure workpiece is anchored or

clamped firmly. If hammerdrilling thin material,

use a wood “back-up” block to prevent damage to

thematerial.

WARNING: To reduce the risk of personal injury,

ALWAYS operate the tool with the side handle

properly installed and securely tightened. Failure

to do so may result in the side handle slipping during

tool operation and subsequent loss of control. Hold

tool with both hands to maximizecontrol.

Proper Hand Position (Fig. F)

WARNING: To reduce the risk of serious personal injury,

ALWAYS use proper hand position as shown.

WARNING: To reduce the risk of serious personal

injury, ALWAYS hold securely in anticipation of a

suddenreaction.

Proper hand position requires one hand on the side

handle

3

, with the other hand on the main handle

4

.

NOTE: Operating temperature of this tool is 19˚ F to

104˚ F (-7˚C to +40˚C). Using the tool outside of this

temperature range will decrease the life of the tool.

Loading...

Loading...