20

ENGLISH

Wear earprotection.

Wear eyeprotection.

Carryingpoint.

Keep hands away fromblade.

When using the machine in the thicknessing mode, be aware of the direction

of feed. Never use the machine without shavings collector inposition.

When using the machine in the planing mode, be aware of the direction of

feed. Never use the machine without shavings collector inposition.

Make sure that the cutting blades are properly adjusted. Do not allow

the blades to protrude from the cutterhead by more than 1.1mm.

Date Code Position (Fig. A1)

The date code

36

, which also includes the year of manufacture, is printed into thehousing.

Example:

2019 XX XX

Year of Manufacture

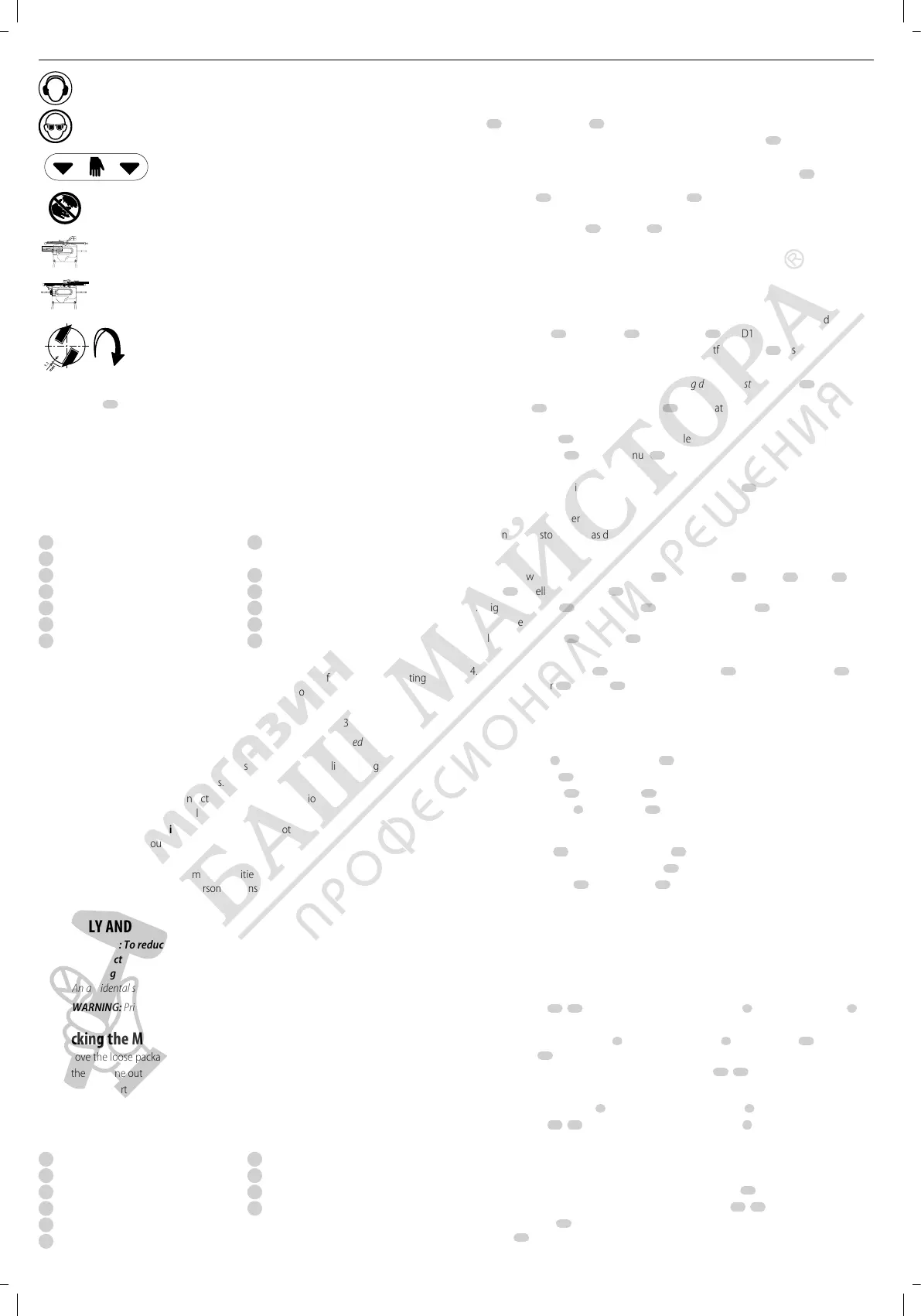

Description (Fig. A1, A2)

WARNING: Never modify the power tool or any part of it. Damage or personal injury

couldresult.

Fig. A1

1

On/off switch

2

Elevating handle

3

Lower table

4

Guard/chip collector

5

Scale lower table

6

Push stick

7

Fence clamp handle

8

Fence

Fig. A2

9

Upper table

10

Planing depth adjustment knob

11

Scale upper table

12

Guard clamp handle

13

Guard

Intended Use

Your DeWALT D27300 Planer and Thicknesser have been designed for professional cutting

of hard and soft wood. It performs planing and thicknessing operations easily, accurately

andsafely.

The cutter block is designed to accept nominal 260 mm blades (DE7333).

WARNING: Do not use the machine for other purposes thanintended.

DO NOT use under wet conditions or in the presence of flammable liquids orgases.

These planers are professional powertools.

DO NOT let children come into contact with the tool. Supervision is required when

inexperienced operators use thistool.

• Young children and the infirm. This appliance is not intended for use by young children

or infirm persons withoutsupervision.

• This product is not intended for use by persons (including children) suffering from

diminished physical, sensory or mental abilities; lack of experience, knowledge or skills

unless they are supervised by a person responsible for their safety. Children should never

be left alone with thisproduct.

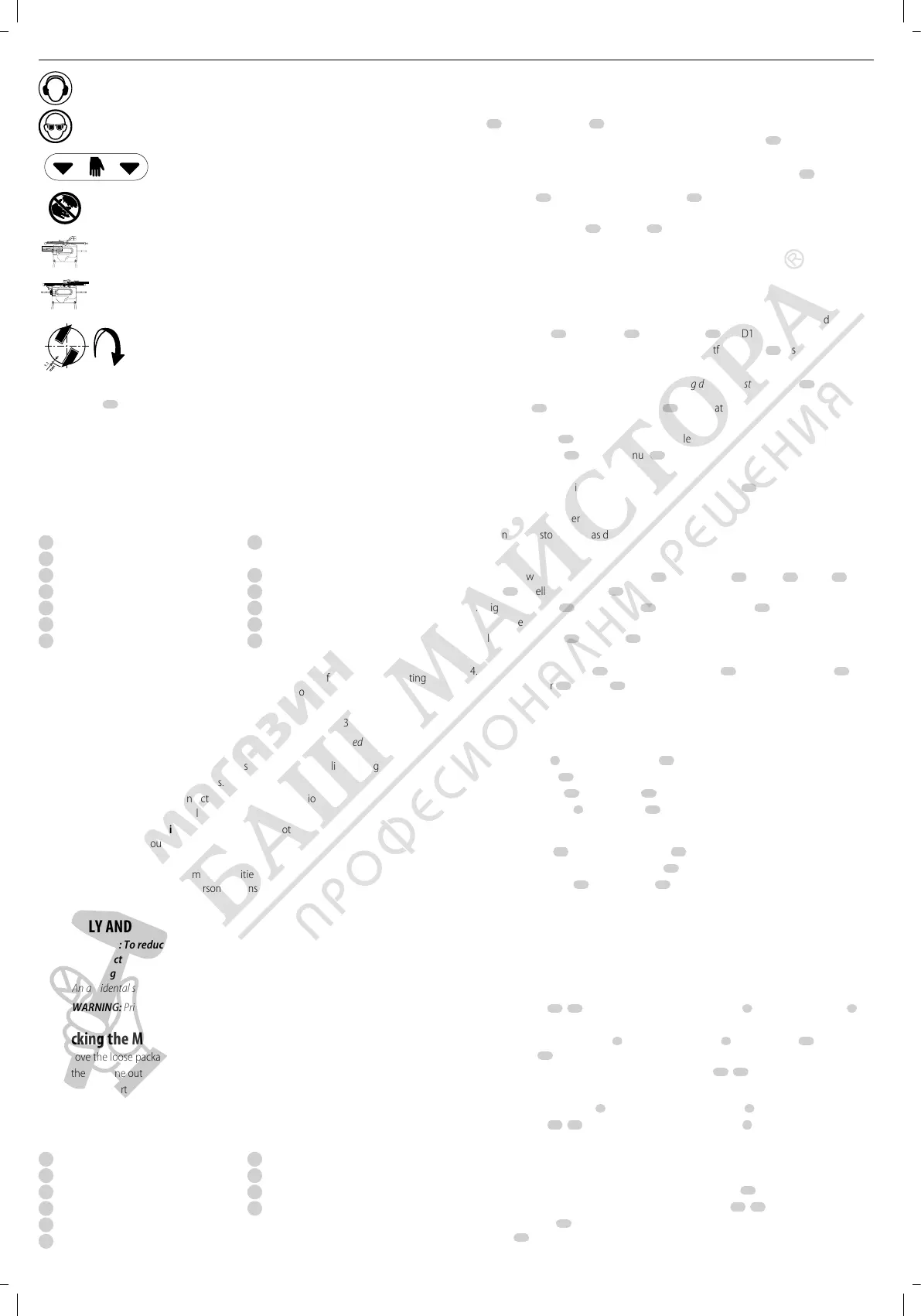

ASSEMBLY AND ADJUSTMENTS

WARNING: To reduce the risk of serious personal injury, turn tool off and

disconnect tool from power source before making any adjustments or removing/

installing attachments or accessories. Be sure the trigger switch is in the OFF position.

An accidental start-up can causeinjury.

WARNING: Prior to assembly always unplug thetool.

Unpacking the Machine (Fig. B1)

1. Remove the loose packaging material from thebox.

2. Lift the machine out of thebox.

3. Remove the parts box from the interior of themachine.

4. Remove any remaining packing material from themachine.

Identifying the Hardware Parts (Fig. B2)

We recommend that you unpack and sort all hardwareparts.

14

Wheel bracket

15

Wheel axle

16

M8 coach bolt

17

M8 hex head bolt

18

M8 nut

19

Wing nut

20

D8 toothed washer

21

D8 flat washer

22

D8 flat washer

23

D8 Belleville washer

Mounting the Feet (Fig. C1, C2)

With the feet mounted, the machine is suitable for placement on a workbench. To ensure a

safe operation, the machine has to be fixed to the workbench. Required hardware parts: 4

nuts

18

, 4 toothed washers

20

(Fig. C1).

1. Turn the machine on its side with the thicknessing outfeed frame

24

resting on the floor

(Fig. C2).

WARNING: Take care to avoid that the planing depth adjustment knob

10

hits thefloor.

2. Insert a foot

25

into each of the outer notches

26

located in the bottom of the

machinehousing.

3. Place a toothed washer

20

and a nut

18

onto the threaded end of thefeet.

4. Tighten thenuts.

5. Turn the machine straightup.

6. Fix the machine to theworkbench.

Mounting the Legs (Fig. D1–D3)

With the legs mounted, the machine is suitable for stand-alone placement. Required hardware

parts: 4 coach bolts

16

, 4 wing nuts

19

, 4 flat washers

21

(Fig D1).

1. Turn the machine on its side with the thicknessing outfeed frame

24

resting on the floor

(Fig. D2).

WARNING: Take care to avoid that the planing depth adjustment knob

10

hits thefloor.

2. Insert a leg

27

into each of the top holes

28

located at the edges in the bottom of the

machinehousing.

3. Pass a coach bolt

16

through the holes in the legs and the machinehousing.

4. Place a flat washer

21

and a wing nut

19

onto thebolts.

5. Tighten the wingnuts.

6. Turn the machine on its side with the planing outfeed table

29

resting on the floor

(Fig.D3).

7. Repeat as for the otherfeet.

8. Mount the castor wheels as describedbelow.

Mounting the Castor Wheels (Fig. E1–E3)

Required hardware parts: 2 wheel brackets

14

, 2 wheel axles

15

, 2 bolts

17

, 4 nuts

18

, 2 flat

washers

21

, 2 Belleville washers

23

(Fig. E1).

1. Align each wheel

30

with a bracket

14

and pass a wheel axle

15

through the holes of

each assembly (Fig. E2).

2. Place a flat washer

21

and a nut

18

onto the threaded end of theaxles.

3. Tighten thenuts.

4. Mount a wheel assembly

31

to each of the upper legs

32

using a hex head bolt

17

,

Belleville washer

23

and nut

18

(Fig. E3).

5. Tighten thenuts.

6. Turn the machine straightup.

Mounting the Fence (Fig. F1, F2)

1. Place the fence

8

onto the fence holder

33

(Fig. F1).

2. Pass a coach bolt

16

from underneath through the holder and thefence.

3. Place a flat washer

22

onto the bolt

16

(Fig. F2).

4. Fit the clamp handle

7

onto the bolt

16

.

Mounting the Bridge Guard (Fig. G1, G2)

1. Insert the guard

13

into the guard column

34

(Fig. G1).

2. Locate the guard by fitting the lock screw

35

.

3. Fit the clamp handle

12

to the column

34

(Fig. G2).

Mounting the Guard/Chip Collector

When using the machine in planing mode, the guard/chip collector has to be mounted

underneath the upper table. When using the machine in thicknessing mode, the guard/chip

collector has to be mounted on top of the uppertable.

Thicknessing Mode (Fig. A1, H1, H2)

NOTE: The guard/chip collector is in planingmode.

1. Loosen knobs (

68

,

69

) to remove the guard/chip collector

4

from the upper table

9

.

2. Turn the guard/chip collector over 180˚.

3. Slide the guard/chip collector

4

along the upper table

9

, until the knob

67

aligns with

microswitch

66

.

4. Fix the guard/chip collector by tightening the knobs (

68

,

69

).

Planing Mode (Fig. G1, G2, H3, H4)

1. Turn the elevating handle

2

to totally lower the under table

9

.

2. Loosen knobs (

68

,

69

) to remove the guard/chip collector

4

from the uppertable.

3. Slide guard/chip collector off of uppertable.

4. Turn the guard/chip collector over 180˚.

5. Align the 2 external dust port ribs of the guard/chip collector with the 2 side panelslots.

6. Slide the guard/chip collector forward into the microswitch

66

.

7. Secure the guard/chip collector by tightening the knobs (

68

,

69

).

8. Lower the guard

13

untill it contacts the chip collector and lock it using the guard

clamp

12

).

Loading...

Loading...