ENGLISH

32

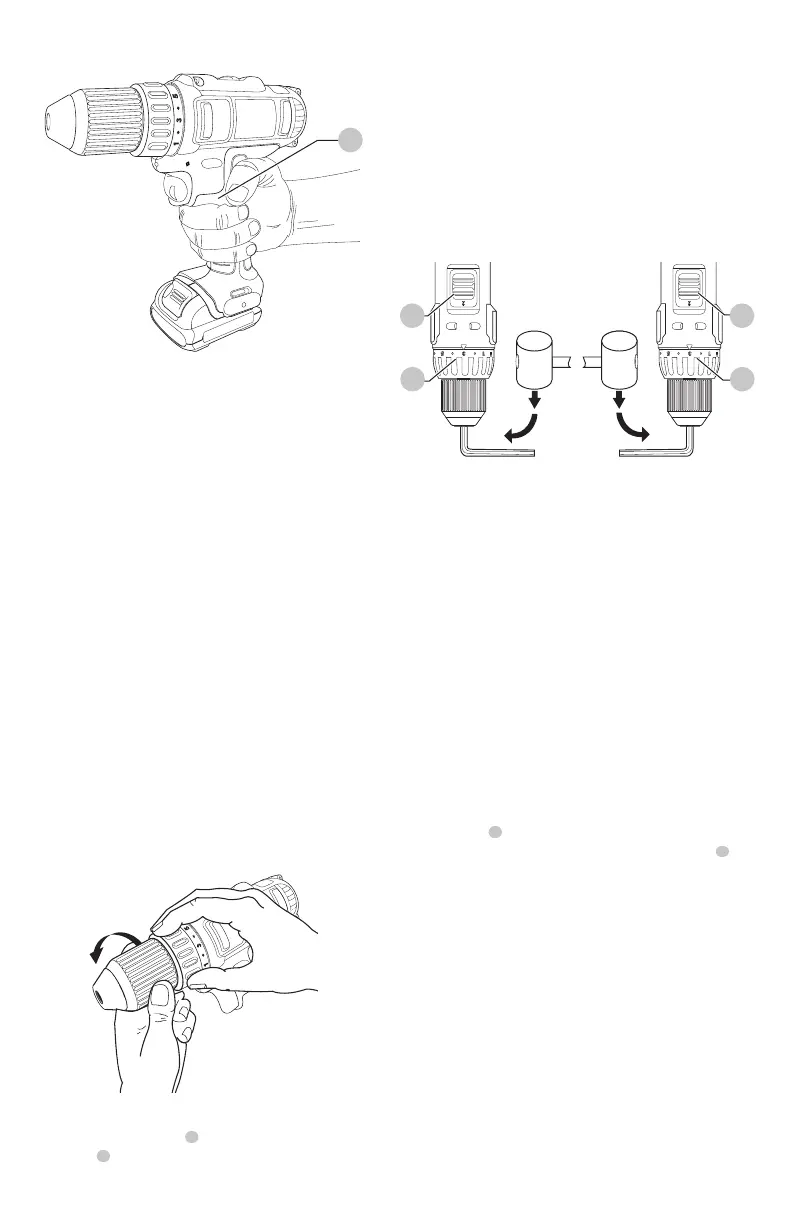

Fig. E

11

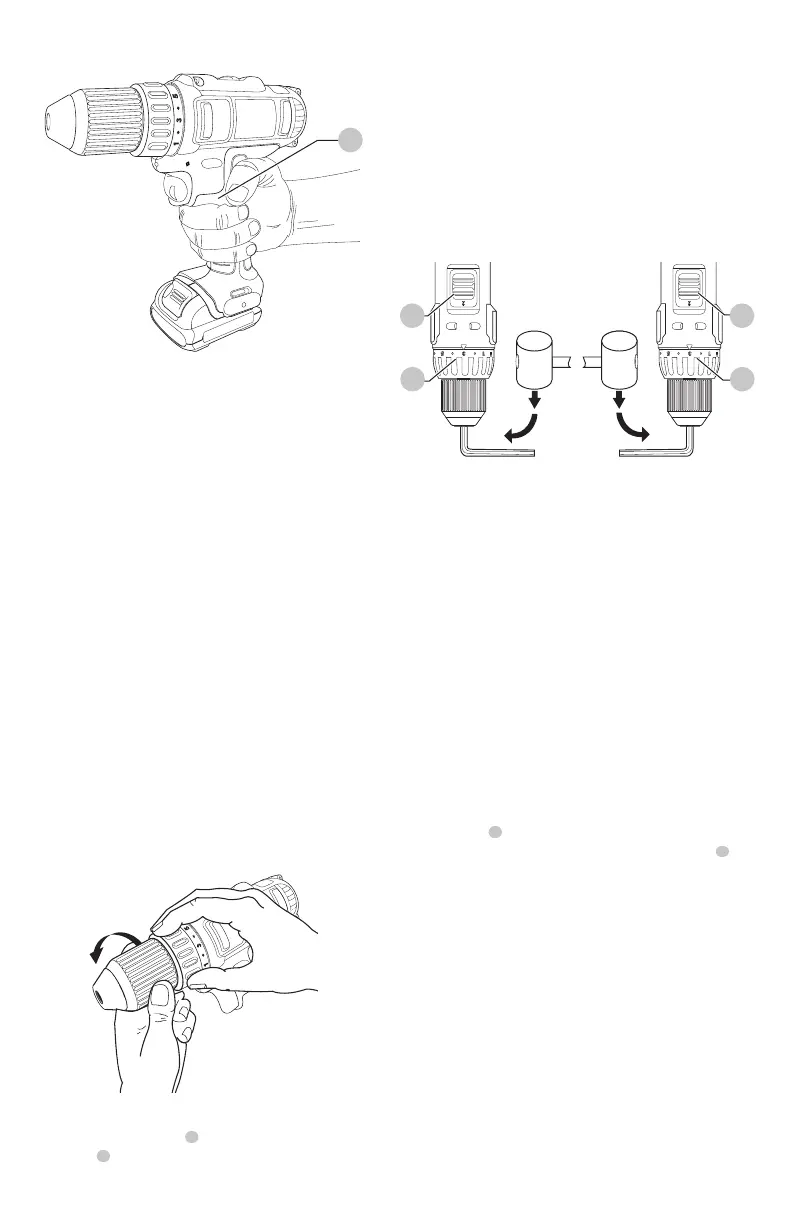

Keyless Single Sleeve Chuck (Fig. F)

Your tool features a keyless chuck with one rotating sleeve

for one-handed operation of the chuck. To insert a drill bit or

other accessory, follow thesesteps.

1. Lock the trigger in the OFF position as

previouslydescribed.

2. Grasp the black sleeve of the chuck with one hand

and use the other hand to secure the tool. Rotate the

sleeve counterclockwise far enough to accept the

desiredaccessory.

3. Insert the accessory about 3/4" (19 mm) into the chuck

and tighten securely by rotating the chuck sleeve

clockwise with one hand while holding the tool with the

other. Your tool is equipped with an automatic spindle

lock mechanism. This allows you to open and close the

chuck with onehand.

4. To release the accessory, repeat step 2above.

WARNING: Do not attempt to tighten drill bits (or

any other accessory) by gripping the front part of the

chuck and turning the tool on. Damage to the chuck

and personal injury may result. Always lock off trigger

switch when changingacces sories.

5. Be sure to tighten chuck with one hand on the

chuck sleeve and one hand holding the tool for

maximumtightness.

Fig. F

Chuck Removal (Fig. G)

Turn the adjustment collar

4

to the “drill” position and

gear shifter

5

to position 1 (low speed). Tighten the chuck

around the shorter end of a hex key (not supplied) of 1/4"

(6mm) or greater size. Using a wooden mallet or similar

object, strike the longer end in the clockwise direction, as

shown. This will loosen the screw inside thechuck.

Open chuck jaws fully, insert screwdriver (or Torx tool if

required) into front of chuck between jaws to engage

screw head. Remove screw by turning clockwise (left-hand-

thread). Place hex key in chuck and tighten, as shown in

FigureH. Using a wooden mallet or similar object, strike key

sharply in the counterclockwise direction. This will loosen

the chuck so that it can be unscrewed byhand.

Fig. G

Fig. H

4

5

4

5

Chuck Installation (Fig. H)

Screw the chuck on by hand as far as it will go and insert

screw (left-hand thread). Tighten screw securely. Tighten

the chuck around the shorter end of a 1/4" (6mm) or larger

hex key (not supplied) strike the longer end in the clockwise

direction with a wooden mallet, as shown. Tighten the

screw once again by turning in a counterclockwisedirection.

Drill Operation (Fig. A)

WARNING: To reduce the risk of serious personal

injury, turn tool off and disconnect tool from

power source before making any adjustments or

removing/installing attachments or accessories.

An accidental start-up can causeinjury.

WARNING: TO REDUCE THE RISK OF PERSONAL

INJURY, ALWAYS ensure workpiece is anchored or

clamped firmly. If drilling thin material, use a wood

“back-up” block to prevent damage to thematerial.

Turn the collar

4

to the drill bit symbol for drilling. Select

the desired speed/torque range using the gear shifter

5

to

match the speed and torque to the plannedoperation.

1. Use sharp drill bits only. For WOOD, use twist drill bits,

spade bits, or hole saws. For METAL, use high-speed

steel (HSS) twist drill bits or holesaws.

2. Always apply pressure in a straight line with the bit. Use

enough pressure to keep drill biting, but do not push

hard enough to stall the motor or deflect thebit.

3. Hold tool firmly with both hands to control the twisting

action of thedrill.

WARNING: The drill may stall if overloaded causing

a sudden twist. Always expect the stall. Grip the drill

firmly with both hands to control the twisting action

and avoidinjury.

4. IF DRILL STALLS, it is usually because it is being

overloaded or improperly used. RELEASE TRIGGER

Loading...

Loading...