ENGLISH

11

Power

Setting

Application Typical Staple Length

1

Shorter staple length / minimal

staple drive desired

1-1/2" (38 mm) typical

2

Increased staple drive desired for

medium to large staple lengths

1-3/4"–2"

(44.4 mm–51.1 mm) typical

3 Maximum staple drive desired

1-3/4"–2"

(44.14 mm–51.1 mm) typical

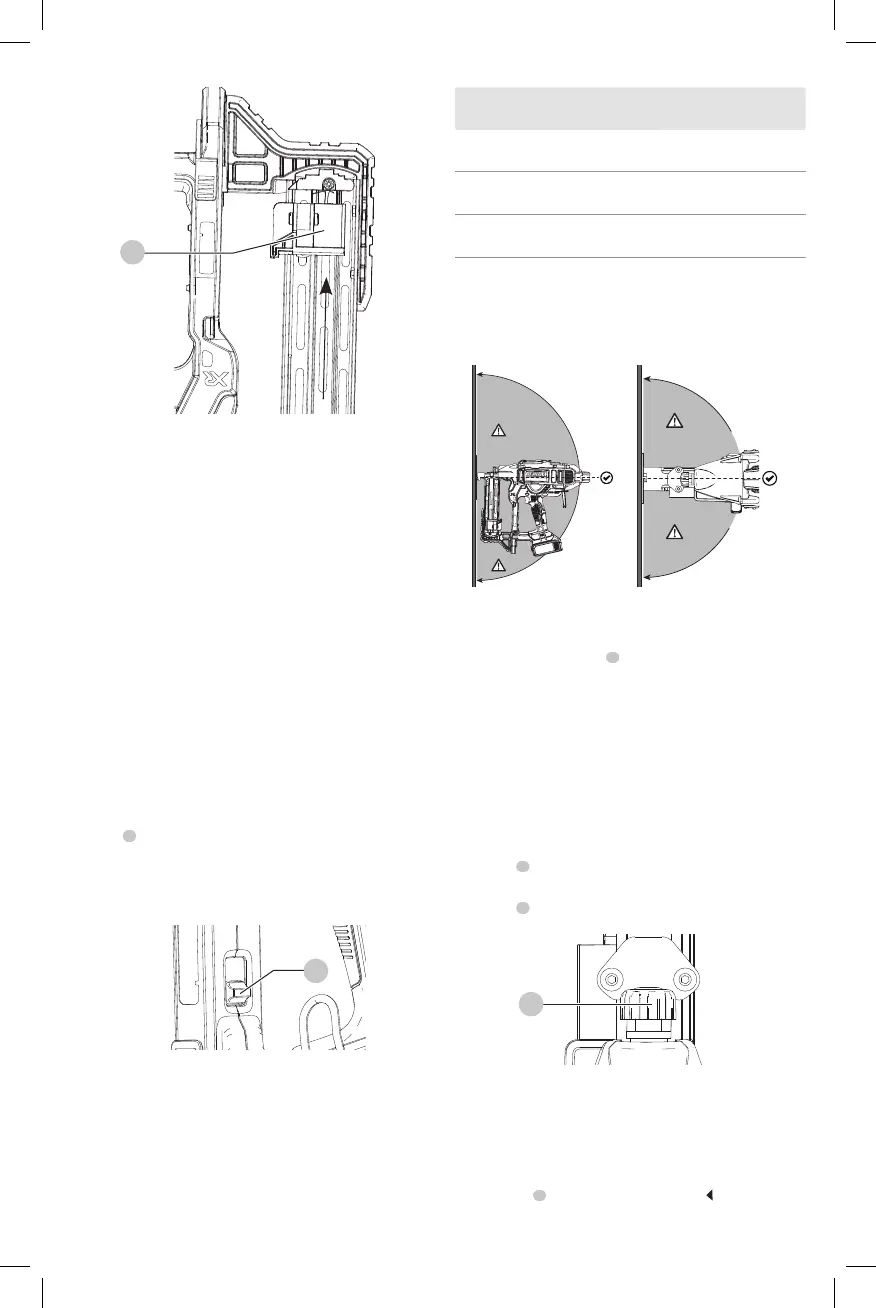

WARNING: Staples must be driven straight into the

material. Do not tilt stapler while driving fasteners.

Refer to Fig.J. Staple retention values improve when

the tool is fired perpendicular to thematerial.

Fig. J

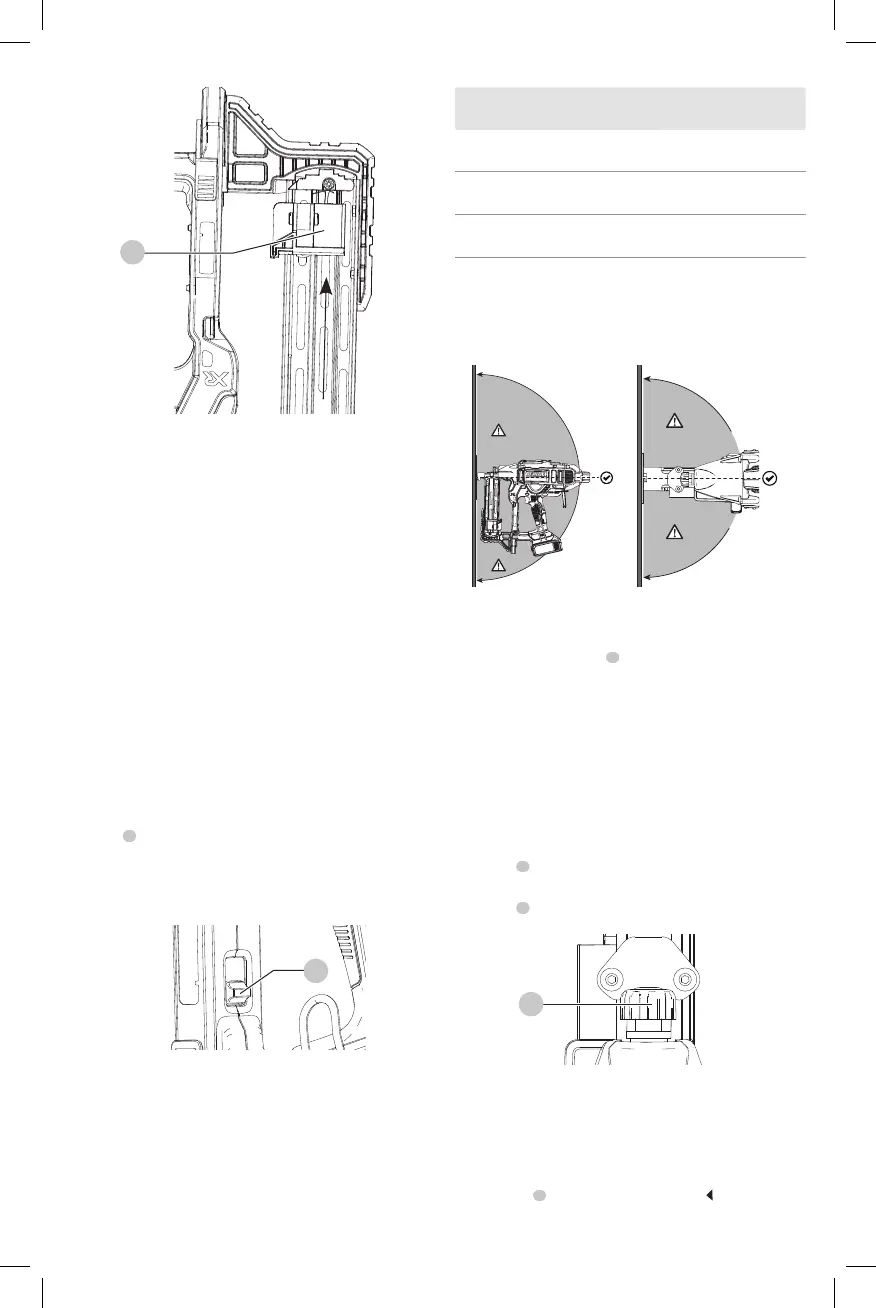

Adjusting Depth (Fig. K)

The depth that the staple is driven can be adjusted using

the tool free depth adjust

6

on the nose of thetool.

WARNING: To reduce risk of serious injury from

accidental actuation when attempting to adjust

depth, ALWAYS:

• Remove battery pack

• Engage trigger lock-off.

• Always point the nose of the stapler away

fromyou.

• Avoid contact with trigger duringadjustments.

1. To drive the staple shallower, rotate the tool free depth

adjust

6

to the left.

2. To drive a staple deeper, rotate the tool free depth

adjust

6

to the right.

Fig. K

6

Selecting the Mode (Fig. A)

WARNING: Always wear proper eye [ANSI Z87.1

(CAN/CSA Z94.3)] and ANSI S12.6 (S3.19) hearing

protection when operatingtool.

To select standard sequential mode, slide the tool free mode

select switch

4

to display the single arrow icon.

Fig. H

12

3. Drop staple strips into the loading slot of the magazine,

making sure the staple heads align correctly with

the slot opening. (Refer to Staple Specifications to

determine compatible size.)

4. Keeping fingers clear of the track, close the magazine by

releasing the pusher latch. Carefully allow the latch to

slide forward and engage the staplestrip.

Unloading the Tool

WARNING: The trigger lock-off should always be

locked off whenever any adjustments are made or

when tool is not inuse.

1. Slide the spring-loaded pusher to the base of the

magazine to lock it intoplace.

2. Tip the tool up until the fastener strip slides freely out of

themagazine.

3. With battery removed, check the nosepiece to verify

there are no staplesremaining.

Power Setting Summary (Fig. I, J)

This stapler is equipped with a tool free power select

switch

3

to adjust the tool for differentapplications.

In the event staples are not driving to depth in power

setting1, you may have to switch to power 2 or 3 for

additional drivingpower.

Fig. I

3

NOTICE: Driving staples into soft materials at

high power settings will cause excessive wear to

your tool and may result in earlyfailures.

Loading...

Loading...