ENGLISH

14

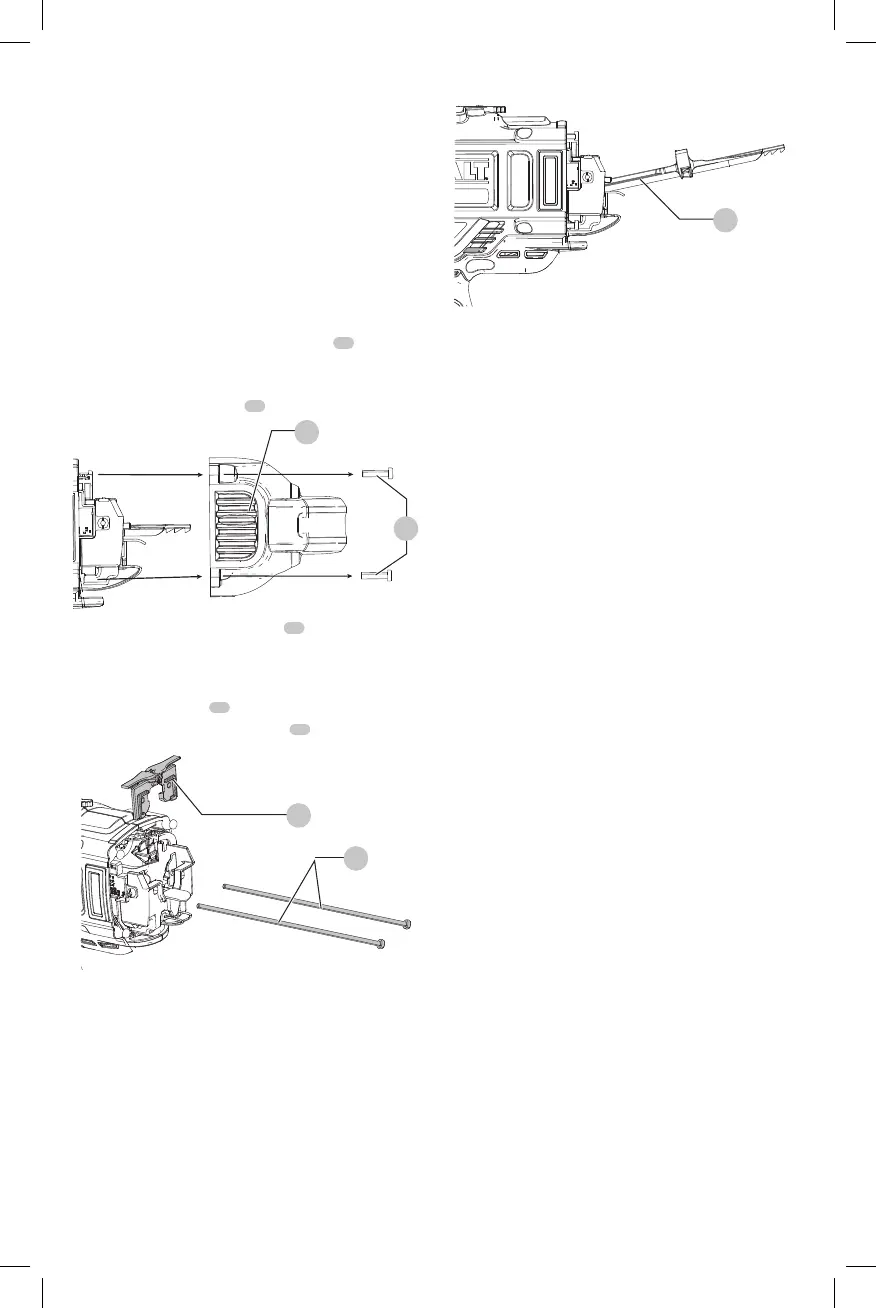

Fig. P

19

10. Return the driver, guide rods, bumpers and housing

end cap back onto the unit. It is important to try

the alignment of the driver and the flywheel before

screwing the housing end cap back on to the unit. This

can be done by connecting a battery and pushing then

releasing the nose of the unit against a bench or hard

surface. This will start the motorspinning.

NOTE: When the driver and the flywheel are correctly

aligned, you will hear the motor coast back down

from full speed. If the driver and the flywheel are not

correctly aligned, the motor may not start up, may

slow down much faster than normal along with a loud

grinding noise from the unit. If this happens remove

and reseat the driver, making sure the bumpers are

seatedcorrectly.

WARNING: Always test the unit by firing 1-1/2"

(38mm) staples in power setting 1 into scrap material,

to ensure that the tool is working properly. If tool does

not operate properly, contact a recognized

service centerimmediately.

Recommended accessories for use with your tool are

available at extra cost from your local dealer or authorized

service center. If you need assistance in locating any

accessory, please contact

Industrial Tool Co., 701

East Joppa Road, Towson, MD 21286, call 1–800–4-

(1–800–433–9258) or visit our website www.

.com.

Repairs

The charger and battery pack are notserviceable.

WARNING: To assure product SAFETY and

RELIABILITY, repairs, maintenance and adjustment

(including brush inspection and replacement) should

be performed by a

factory service center

or a

authorized service center. Always use

identical replacementparts.

Register Online

Thank you for your purchase. Register your product nowfor:

• WARRANTY SERVICE: Registering your product will

help you obtain more efficient warranty service in case

there is a problem with yourproduct.

• CONFIRMATION OF OWNERSHIP: In case of

an insurance loss, such as fire, flood or theft, your

registration of ownership will serve as your proof

ofpurchase.

DCFS9501 Driver Blade Replacement Kit

(Fig. N–P)

WARNING: For your own safety, read the tool

instruction manual before using any accessory.

Failure to heed these warnings may result in serious

personal injury and damage to the tool and the

accessory. When servicing this tool, use only identical

replacementparts.

NOTICE: All the mechanical parts of the driver

replacment kit are shown for convenience and

verification ofinclusion.

To change a worn driver:

1. Using a T-20 Torx, loosen the four screws

17

on either

side of the unit. Refer to FigureN.

2. Remove the four screws. Refer to FigureN.

3. Remove housing end cap

18

. Refer to FigureN.

Fig. N

18

17

4. Push up on the rear of the driver

19

until you hear a

click, then push the driver forward while holding it in

this position until it passes the upper bumper assembly.

Refer to FigureP.

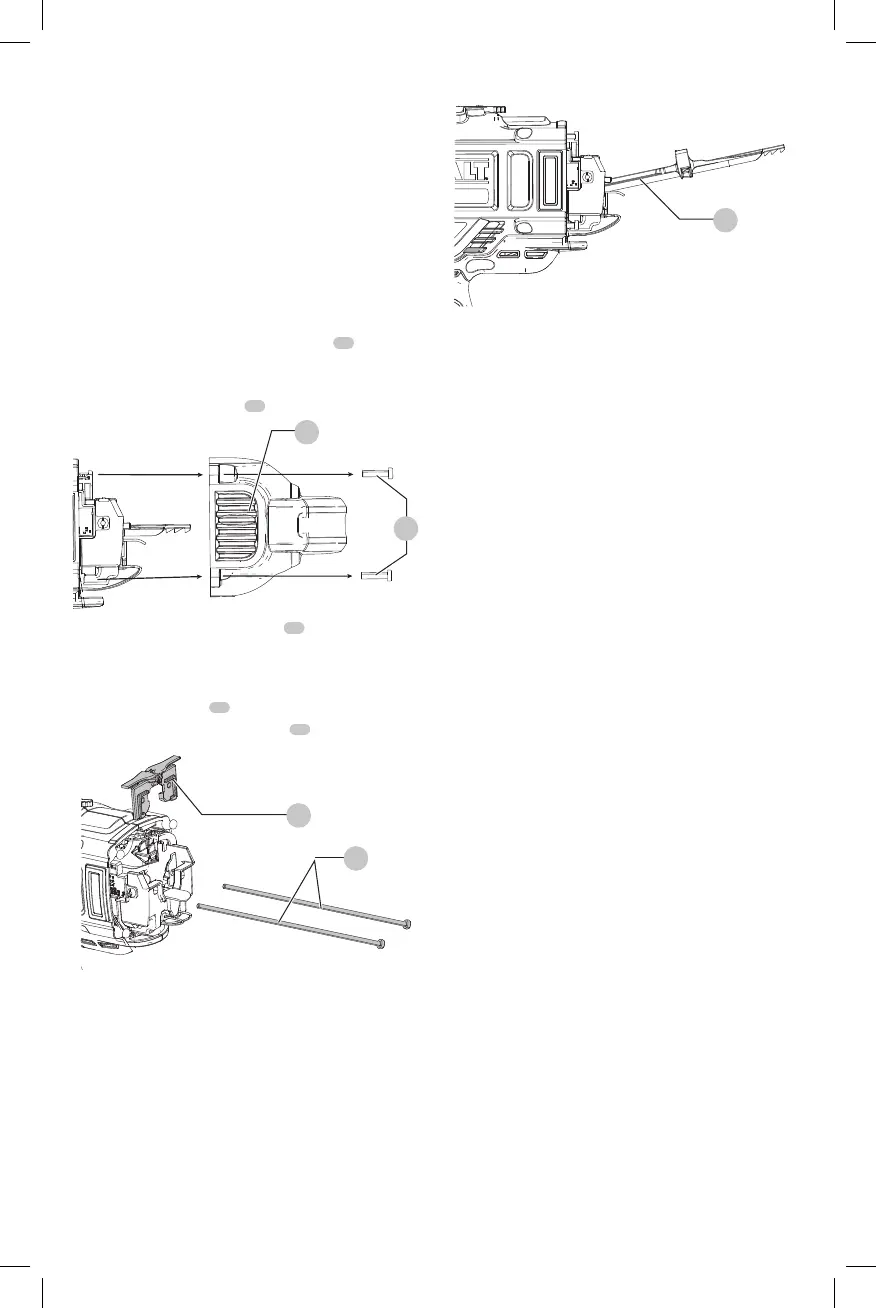

5. Remove guide rods

20

. Refer to FigureO.

6. Remove upper bumper assembly

21

. Refer to FigureO.

Fig. O

20

21

7. Lift the rear of driver until at an angle and pull the driver

out. Refer to FigureP.

8. Replace driver and follow steps in reverse to reassemble

9. Ensure new driver slides smoothly through the gun

before fullreassembly.

Loading...

Loading...