ENGLISH

15

Fig. R

Place the work with its “good” side – the one on which

appearance is most important – down. The saw cuts

upward, so any splintering will be on the work face that is

up when you cutit.

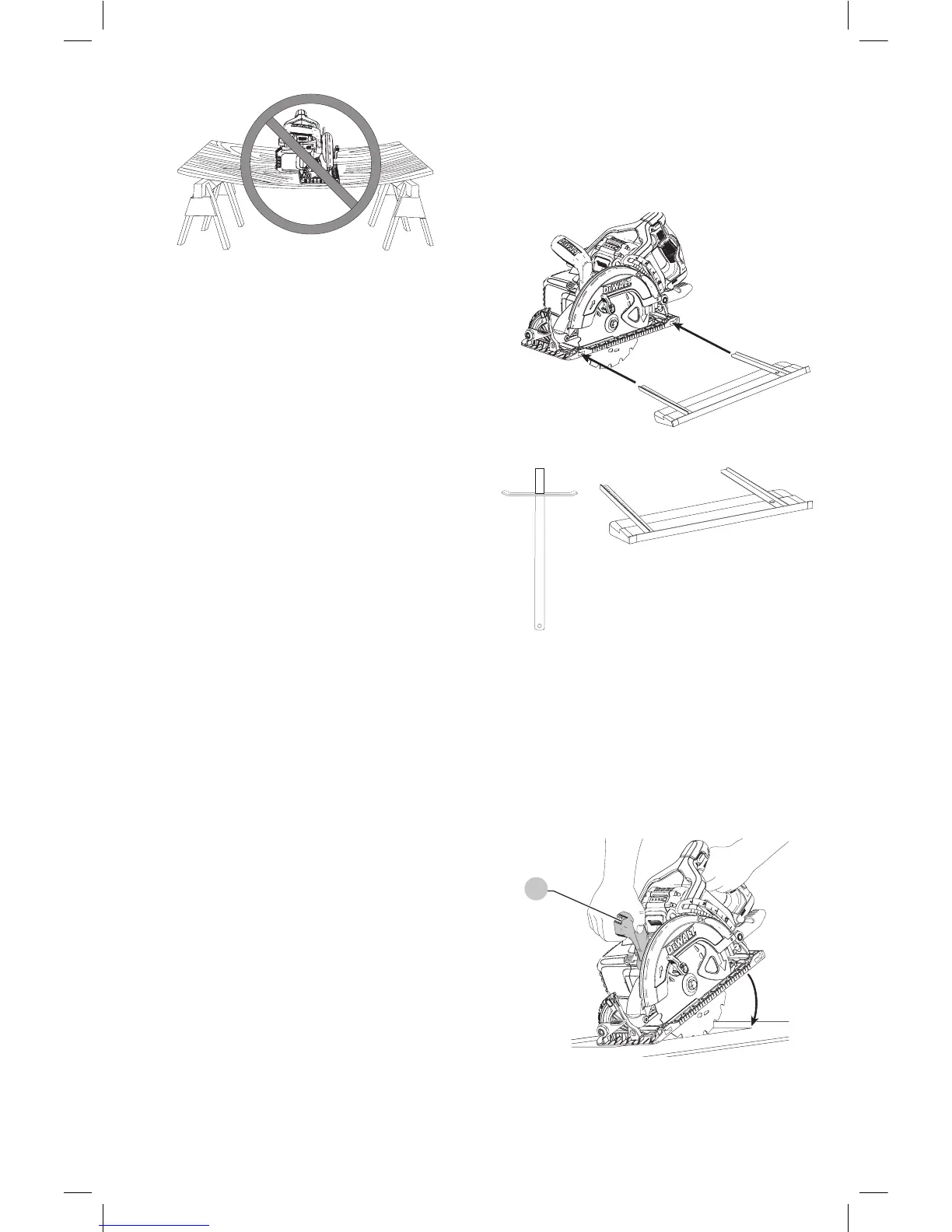

Cutting (Fig. P)

WARNING: Never attempt to use this tool by resting

it upside down on a work surface and bringing

the material to the tool. Always securely clamp

the workpiece and bring the tool to the workpiece,

securely holding the tool with two hands as shown

in FigureP.

Place the wider portion of the saw foot plate on that part

of the work piece which is solidly supported, not on the

section that will fall off when the cut is made. As examples,

FigureP illustrates the RIGHT way to cut off the end of a

board. Always clamp work. Don’t try to hold short pieces by

hand! Remember to support cantilevered and overhanging

material. Use caution when sawing material frombelow.

Be sure saw is up to full speed before blade contacts

material to be cut. Starting saw with blade against material

to be cut or pushed forward into kerf can result in kickback.

Push the saw forward at a speed which allows the blade

to cut without laboring. Hardness and toughness can vary

even in the same piece of material, and knotty or damp

sections can put a heavy load on the saw. When this

happens, push the saw more slowly, but hard enough to

keep working without much decrease in speed. Forcing

the saw can cause rough cuts, inaccuracy, kickback, and

over-heating of the motor. Should your cut begin to go

off the line, don’t try to force it back on. Release the switch

and allow blade to come to a complete stop. Then you can

withdraw the saw, sight anew, and start a new cut slightly

inside the wrong one. In any event, withdraw the saw if you

must shift the cut. Forcing a correction inside the cut can

stall the saw and lead tokickback.

IF SAW STALLS, RELEASE THE TRIGGER AND BACK THE SAW

UNTIL IT IS LOOSE. BE SURE BLADE IS STRAIGHT IN THE CUT

AND CLEAR OF THE CUTTING EDGE BEFORERESTARTING.

As you finish a cut, release the trigger and allow the blade

to stop before lifting the saw from the work. As you lift

the saw, the spring-tensioned telescoping guard will

automatically close under the blade. Remember the blade

is exposed until this occurs. Never reach under the work for

any reason. When you have to retract the telescoping guard

manually (as is necessary for starting pocket cuts) always

use the retractinglever.

NOTE: When cutting thin strips, be careful to ensure that

small cutoff pieces don’t hang up on inside of lowerguard.

Ripping (Fig. S, T1, T2)

Ripping is the process of cutting wider boards into narrower

strips – cutting grain lengthwise. Hand guiding is more

difficult for this type of sawing and the use of either

DW3278 rip guide (Fig. T1) or DWS5100 dual port rip guide

is recommended (Fig.T2).

Fig. S

Fig. T1

Fig. T2

DW3278

DWS5100

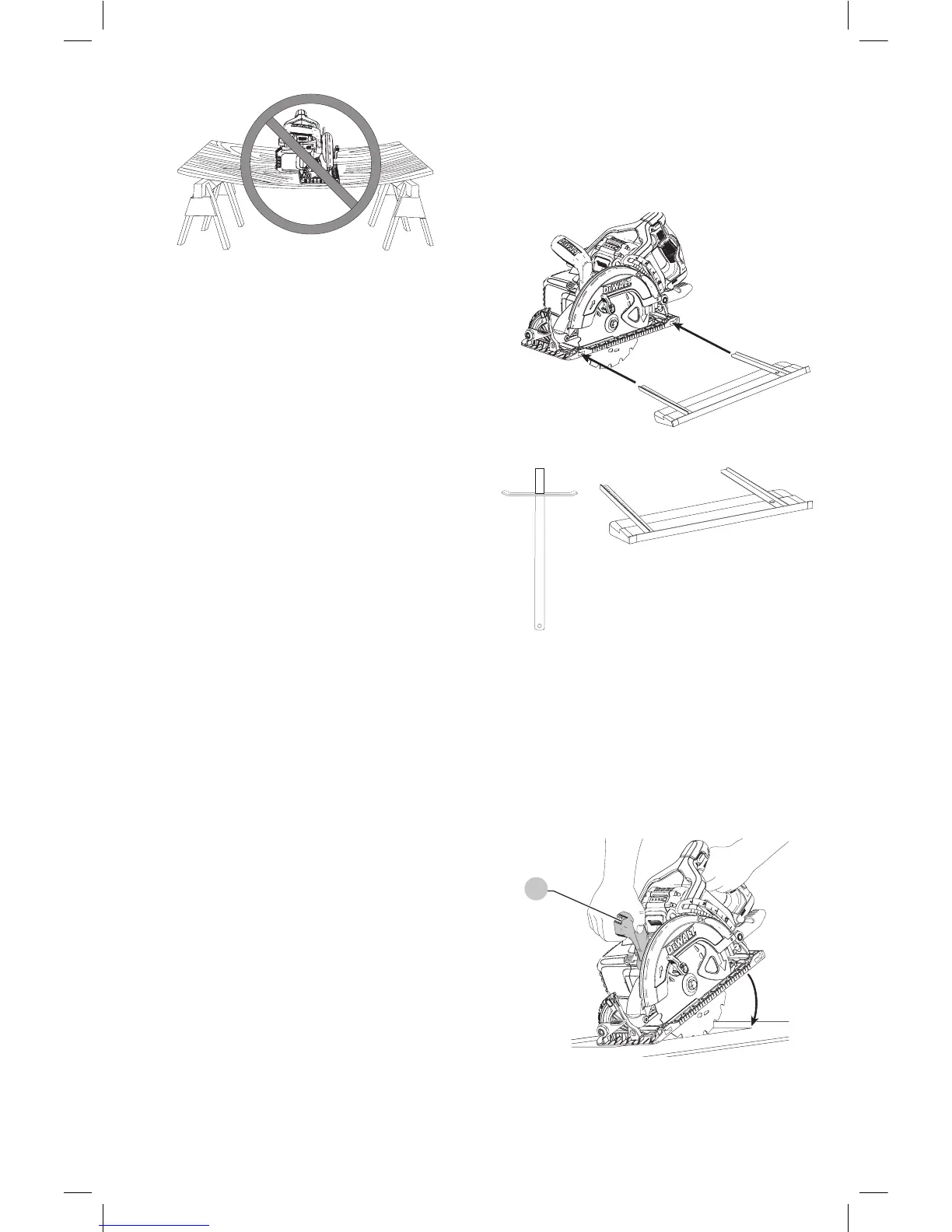

Pocket Cutting (Fig. U)

WARNING: Never tie the blade guard in a raised

position. Never move the saw backwards when

pocket cutting. This may cause the unit to raise

up off the work surface which could causeinjury.

A pocket cut is one that is made in a floor, wall, or other

flatsurface.

Fig. U

13

1. Adjust the saw foot plate so the blade cuts at

desireddepth.

2. Tilt the saw forward and rest front of the foot plate on

material to becut.

Loading...

Loading...