14

DANSK

1. Løsn vinkellåsegrebet

20

og indstil den ønskedevinkel.

2. Indstil om nødvendigt tilsidesættelsesknappen

31

.

3. Hold hovedet fast og lad det ikkefalde.

4. Spænd vinkellåsegrebet

20

fast.

5. Fortsæt som ved den lige lodretteskæring.

Snitkvalitet

Glatheden af alle snit er afhængigt af adskillige variabler, som f.eks. det

materiale der skæres. Hvis du ønsker meget glatte snit til kantprofiler og

andet præcisionsarbejde, vil en skarp (60-tandet hårdtmetal) klinge og en

langsommere, jævn snithastighed frembringe de ønskederesultater.

ADVARSEL: Kontrollér at materialet ikke kryber under skæring;

fastspænd det godt på plads. Lad altid klingen komme til et fuldt stop,

før armen hæves. Hvis der stadig er små træsplinter, som stikker ud af

enden på arbejdsemnet, skal der anbringes et stykke afdækningstape

på træet, hvor snittet skal være. Sav gennem tapen og fjern

omhyggeligt tapen, når skæringen erafsluttet.

Fastspænding af arbejdsemnet (Fig. T)

ADVARSEL: Brug altid enmaterialeholder.

For at opnå det bedste resultater skal der anvendes en materialeholder

17

,

som er blevet konstrueret til anvendelse med dinsav.

Sådan monteres holderen

1. Indsæt den i hullet bag ved anslaget. Holderen

17

skal vende imod

geringssavens bagside. Kontrollér at rillen på holderstangen er helt

indsat i geringssavens fundament. Hvis rillen er synlig, er holderen ikke

sikkertfastgjort.

2. Drej holderen 180º imod geringssavensforside.

3. Løsn knappen for at justere holderen op eller ned, og anvend derefter

finjusteringsknappen til at fastgørearbejdsemnet.

BEMÆRK: Anbring holderen på højre side af fundamentet under

vinkelskæring. TEST ALTID FØRST MED SLUKKET MASKINE (UDEN STRØM),

INDEN DU UDFØRER SKÆRINGER, SÅ DU KAN KONTROLLERE KLINGENS STI.

HOLDEREN SKAL FASTGØRES SÅLEDES, AT DEN IKKE HAR INDFLYDELSE PÅ

SAVENS ELLER BESKYTTELSESSKÆRMENESFUNKTIONER.

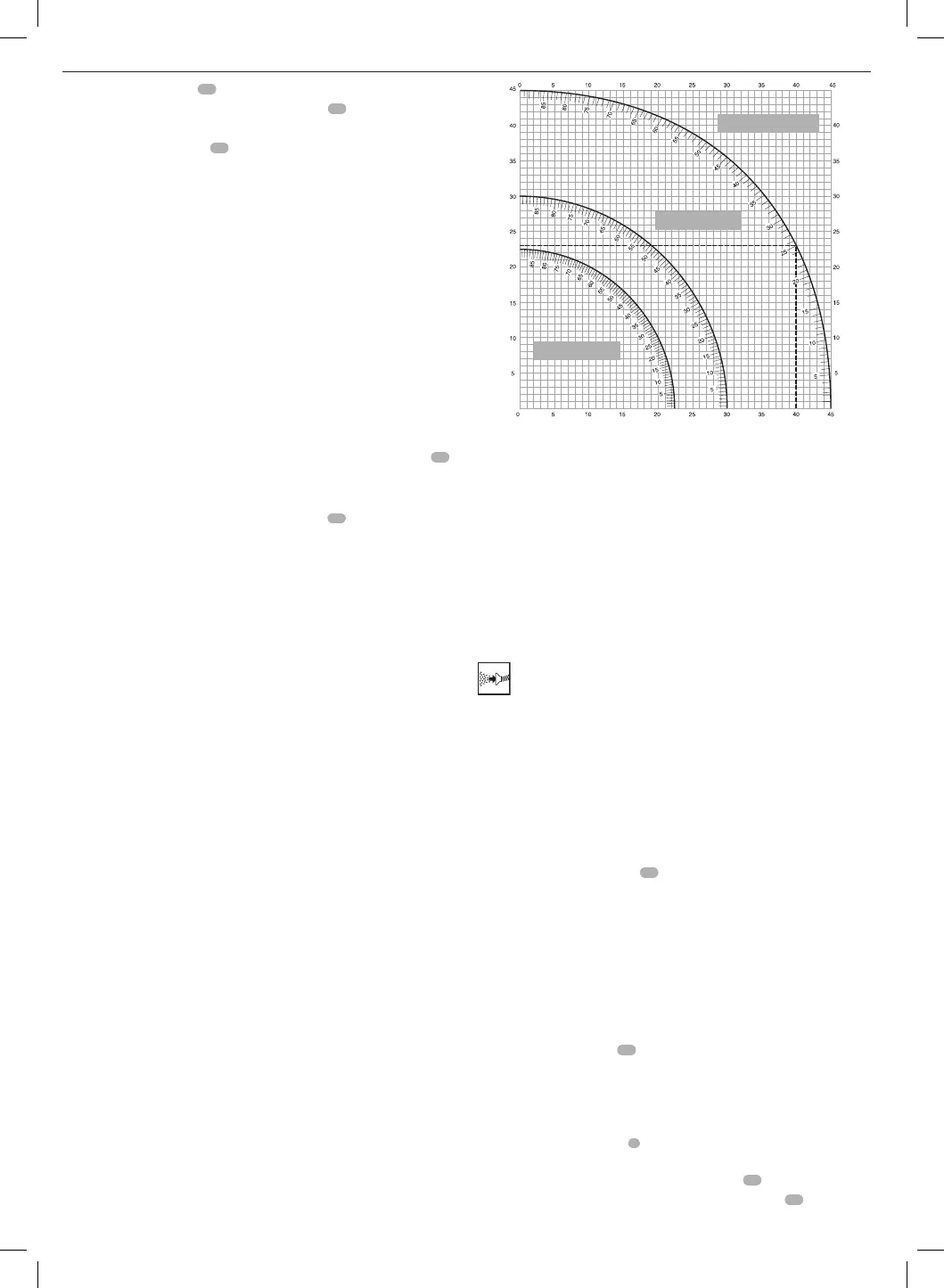

Dobbeltgering (Fig. S)

Denne skæring er en kombination af et gerings- og vinkelsnit. Det er denne

type skæring, der bruges til at lave rammer eller kasser med skrånende sider

som den, der vises i figurS.

ADVARSEL: Hvis skærevinklen varierer fra snit til snit, skal det

kontrolleres at vinkellåsegrebet og geringslåseknappen er spændt

korrekt. De skal spændes fast, efter der er foretaget ændringer af vinkler

ellergering.

• Efterfølgende skema kan hjælpe dig med at vælge de korrekte vinkel-

og geringsindstillinger til gængsedobbeltgeringssnit.

• For at kunne anvende skemaet skal du vælge den ønskede vinkel "A"

(Fig.S) til dit projekt og finde denne vinkel på den passende kurve i

oversigten. Fra dette punkt skal du følge linjen lige nedad på tegningen

for at finde den korrekte hældningsvinkel og lige tværs over for at finde

den korrektegeringsvinkel.

Indstil denne geringsvinkel på saven

Vinkel på kassens side (vinkel "A")

Indstil denne hældningsvinkel på saven

1. Indstil din sav til de foreskrevne vinkler og foretag et parprøvesnit.

2. Øv dig i at sætte de skårne stykkersammen.

Eksempel: For at lave en 4-sidet kasse med 25º udvendige vinkler

(vinkel "A") (Fig.S) skal den øverste højre kurve anvendes. Find 25°

på kurveskalaen. Følg den vandrette skæringslinje til en af siderne

for at finde geringsvinkelindstillingen på saven (23°). Følg på same

måde den lodrette skæringslinje opad eller nedad for at finde

hældningsvinkelindstillingen på saven (40°). Foretag altid prøvesnit på

nogle stykker affaldstræ

for at kontrollere indstillingerne påsaven.

ADVARSEL: Overskrid aldrig dobbeltgeringsgrænserne på 45° vinkel

med 45° gering til venstre ellerhøjre.

Støvopsamling (Fig. A, G)

ADVARSEL: Tilslut, hver gang det er muligt, en støvopsamlingsenhed,

der er konstrueret i henhold til de relevante bestemmelser med hensyn

tilstøvemission.

Tilslut en støvopsamlingsenhed, der er konstrueret i henhold til de relevante

bestemmelser. Lufthastigheden på eksternt tilsluttede systemer skal

være 20m/sek +/- 2 m/sek. Hastigheden skal måles i tilslutningsrøret på

tilslutningspunktet, med tilsluttet værktøj, men ikke idrift.

BEMÆRK: Det anbefales at anvende en hurtigforbindelse

DWV9000 med drejetilslutning

48

som valgfrit tilbehør til at

tilsluttestøvopsamlingsenheden.

Overhold de relevante bestemmelser i dit land for de materialer, der

skalbearbejdes.

Støvsugeren skal være egnet til det materiale, derbearbejdes.

Ved støvsugning af tørt støv, der er særligt sundhedsskadeligt eller

kræftfremkaldende, skal der anvendes en specielstøvsuger.

Transport (Fig. A, B)

ADVARSEL: For at kunne bære geringsaven komfortabelt findes

der to fordybninger

32

til hænderne i bunden. Anvend aldrig

beskyttelsesskærme til at løfte eller transporteregeringsaven.

1. Når saven skal transporteres skal hældningsvinkel- og

geringspositionerne indstilles til 0°.

2. Skub savhovedet helttilbage.

3. Tryk på frigørelsesgrebet

2

til spærremekanismen for den nedre

beskyttelsesskærm (Fig.A).

4. Tryk hovedet nedad og tryk på spærreknappen

23

(Fig.B).

5. Bring savklingen i hvileposition og tryk på tværspærren

18

.

8-SIDET KASSE

FIRKANTET KASSE

6-SIDET KASSE

Loading...

Loading...