ENGLISH

4

more than one extension to make up the total length,

be sure each individual extension contains at least the

minimum wire size. The following table shows the correct

size to use depending on cord length and nameplate

ampere rating. If in doubt, use the next heavier gauge. The

lower the gauge number, the heavier thecord.

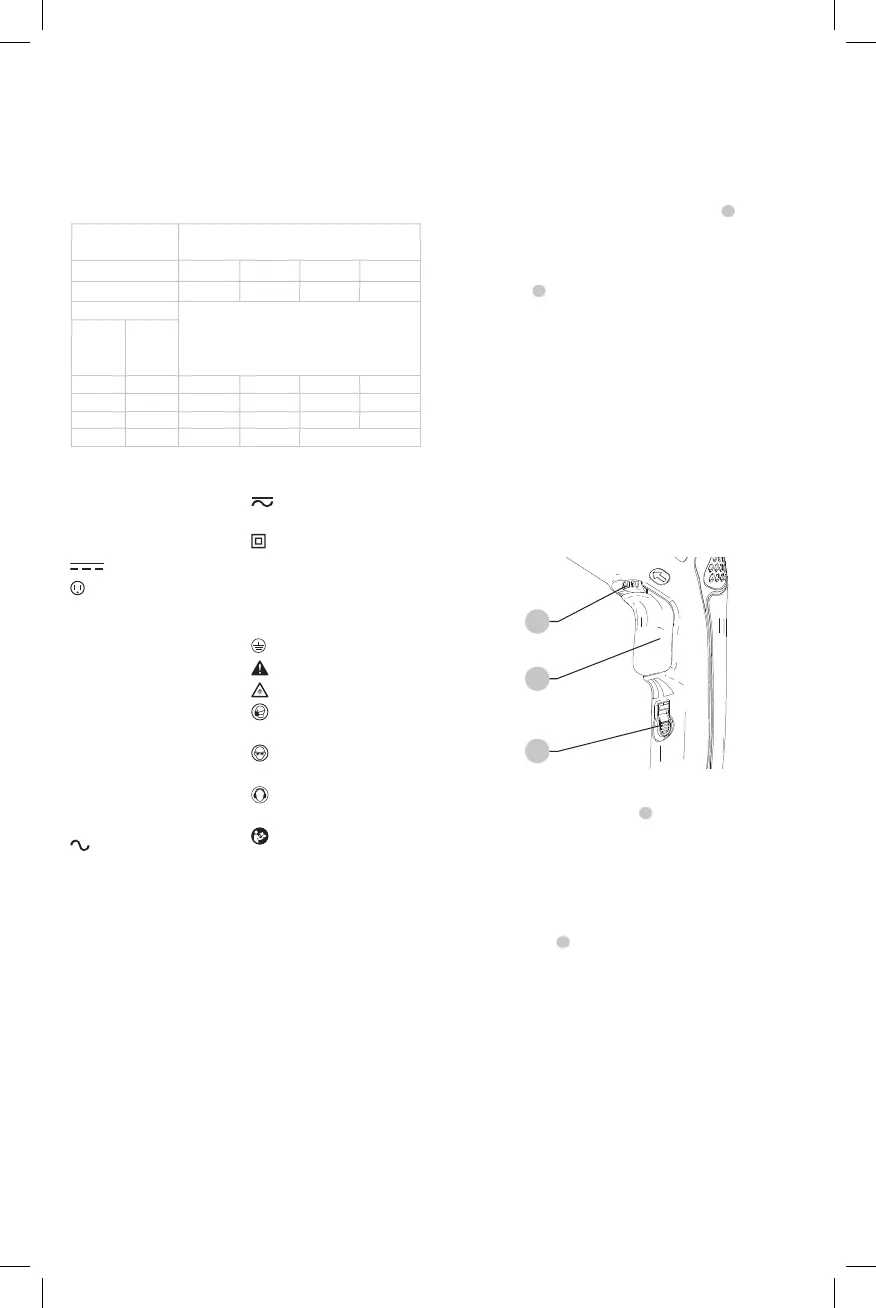

Minimum Gauge for Cord Sets

Volts

Total Length of Cord in Feet

(meters)

120 V 25 (7.6) 50 (15.2) 100 (30.5) 150 (45.7)

240 V 50 (15.2) 100 (30.5) 200 (61.0) 300 (91.4)

Ampere Rating

American Wire Gauge

More

Than

Not

More

Than

0 6 18 16 16 14

6 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12 Not Recommended

The label on your tool may include the following symbols. The

symbols and their definitions are asfollows:

V ......................... volts

Hz .......................hertz

min ..................... minutes

or DC ......direct current

...................... Class I Construction

(grounded)

…/min ..............per minute

BPM .................... beats per minute

IPM ..................... impacts per minute

RPM .................... revolutions per

minute

sfpm ................... surface feet per

minute

SPM .................... strokes per minute

A ......................... amperes

W ........................watts

or AC ...........alternating current

or AC/DC .... alternating or

direct current

...................... Class II

Construction

(double insulated)

n

o

.......................no load speed

n .........................rated speed

......................earthing terminal

.....................safety alert symbol

.....................visible radiation

..................... wear respiratory

protection

..................... wear eye

protection

..................... wear hearing

protection

..................... read all

documentation

SAVE THESE INSTRUCTIONS FOR

FUTURE USE

Motor

Be sure your power supply agrees with the nameplate

marking. Voltage decrease of more than 10% will cause loss

of power and overheating.

tools are factory tested;

if this tool does not operate, check powersupply.

Intended Use

These heavy-duty hammerdrills are designed for

professional drilling and hammerdrilling. DO NOT use

under humid conditions or in presence of flammable liquids

orgases.

NOTICE: Not recommended for mixingapplications.

These heavy-duty hammerdrills are professional power

tools. DO NOT let children come into contact with the tool.

Supervision is required when inexperienced operators use

thistool.

DO NOT use under wet conditions or in presence of

flammable liquids orgases.

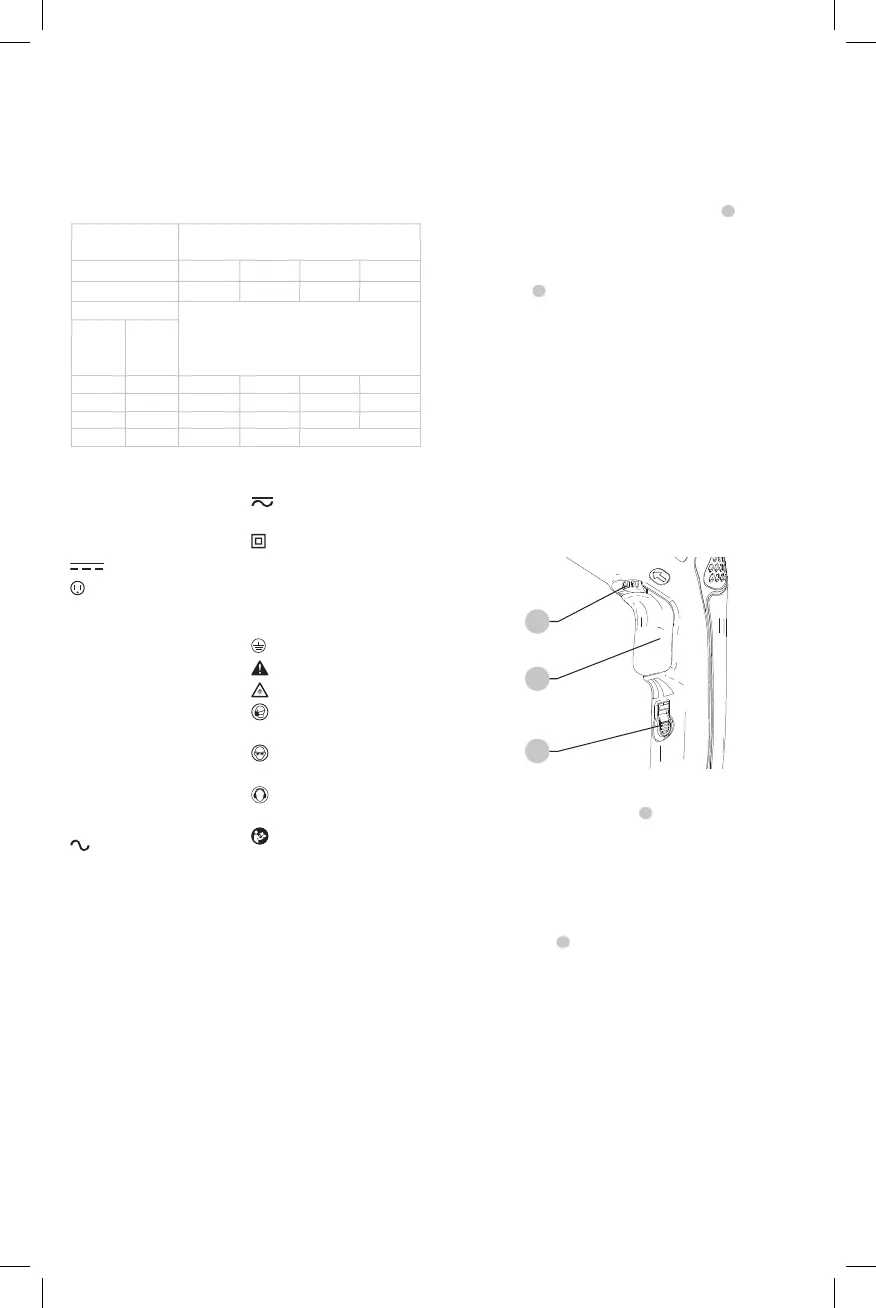

Switch (Fig. B)

To start hammerdrill, depress the trigger switch

1

. To stop

hammerdrill, release theswitch.

To lock the trigger switch in the ON position for continuous

operation, depress the trigger switch and push up the

locking button

2

. The tool will continue torun.

To turn the tool OFF from a locked on condition, squeeze

and release the trigger once. Before using the tool (each

time), be sure that the locking button release mechanism is

workingfreely.

The locking button is for use only when the hammerdrill is

mounted in a drill press stand or otherwise held stationary.

Do not lock the switch ON when drilling by hand so that

you can instantly release the trigger switch if the bit binds in

the hole. Be sure to release the locking mechanism before

disconnecting the plug from the power supply. Failure to do

so will cause the hammerdrill to start immediately the next

time it is plugged in. Damage or injury couldresult.

Fig. B

3

1

2

Variable Speed Trigger Switch (Fig. B)

The variable speed trigger switch

1

permits speed control.

The farther the trigger switch is depressed, the higher the

speed of thehammerdrill.

NOTE: Use lower speeds for starting holes, drilling in plastics

or ceramics or drivingscrews.

Reversing Lever (Fig. B)

The reversing lever

3

, located above the trigger switch,

changes the direction of rotation of the hammerdrill and is

used when backing out screws and jammed drillbits.

To operate the tool in reverse, release the trigger switch

and push the lever to the left (when viewed from the

chuckend).

To operate the drill in forward, release the trigger switch

and push the lever to the right (when viewed from the

chuckend).

Return the reversing lever to the forward position after all

operations in reverse arecompleted.

Loading...

Loading...