ENGLISH

5

Side Handle (Fig. A, C)

WARNING: To reduce the risk of personal injury,

ALWAYS operate the tool with the side handle

properly installed and tightened. Failure to do

so may result in the side handle slipping during tool

operation and subsequent loss of control. Hold tool

with both hands to maximizecontrol.

A side handle

4

may be supplied with this hammerdrill. It

clamps to the front of the gear case as shown in FigureC

and can be rotated 360˚ for right- or left- hand use. Rotate

clockwise until securelytightened.

4

6

Fig. C

Hammer/Drill Selector (Fig. A)

To switch the tool from the drilling mode to the hammering

mode (or vice-versa) rotate the selector dial

5

on the

applicable symbol shown in FigureA. For straight drilling,

align the drill bit symbol toward the chuck. For hammering,

align the hammer symbol with the lever, asshown.

NOTE: The selector must be in either drill or hammer/drill

mode at all times. There are no operable positions between

the twomodes.

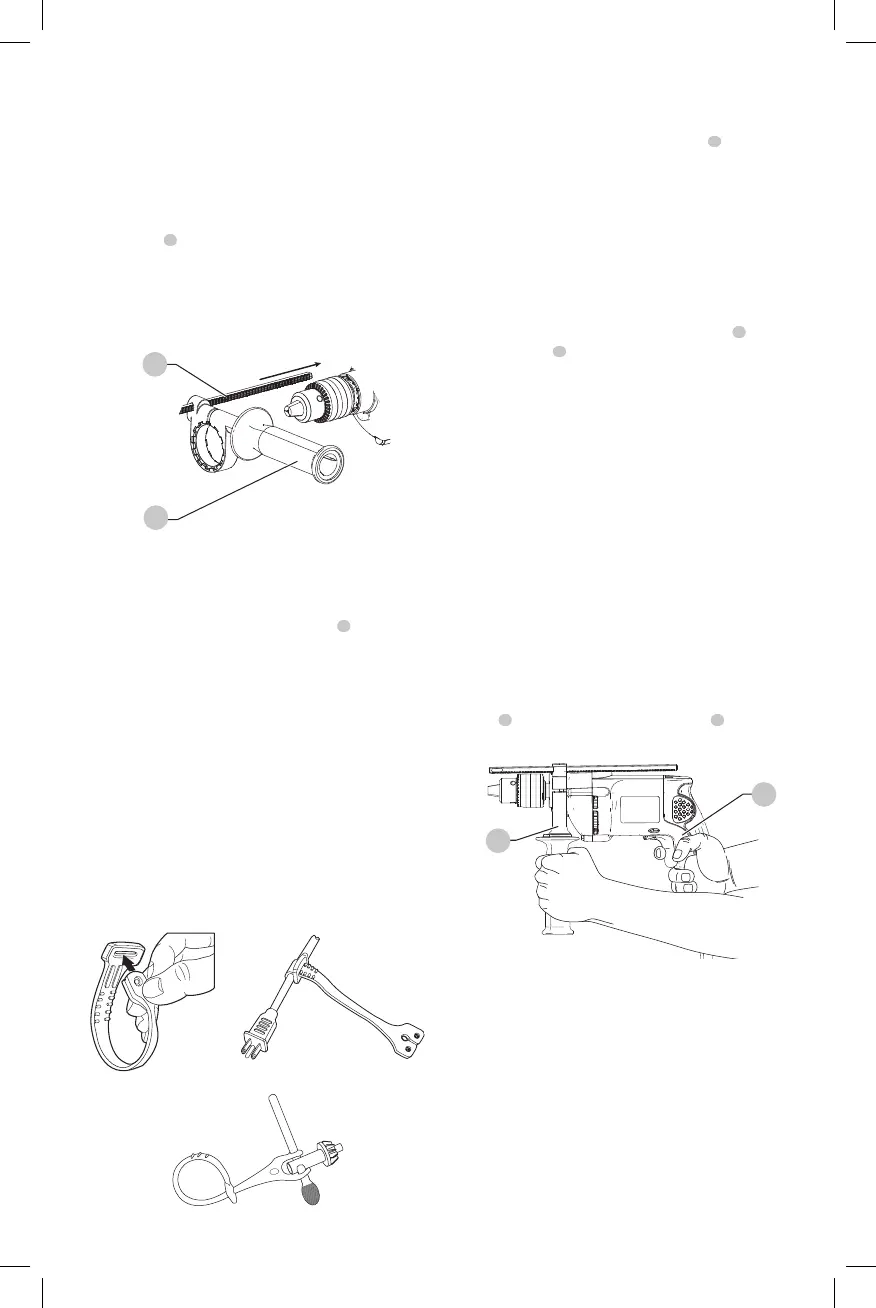

Chuck Key Holder (Fig. D, E, F)

1. Push double-hole end of holder through the slot in

other end of holder (Fig. D).

2. Slip loop over electric plug and draw loop tight around

cord (Fig. E).

3. Push ends of chuck key handle (long end first) through

two holes in end of holder (Fig. F).

Fig. E

Fig. D

Fig. F

Keyed Chuck (Fig. A)

Open chuck jaws by turning collar with fingers and insert

shank of bit about 3/4" (19mm) into chuck

7

. Tighten

chuck collar by hand. Place chuck key in each of the three

holes, and tighten in clockwise direction. It’s important to

tighten chuck with all three holes to prevent slippage. To

release bit, turn chuck key counterclockwise in just one hole,

then loosen the chuck by hand. Any authorized

service center can install a keyless chuck in place of a

keyedchuck.

Depth Rod (Fig. A, C)

To adjust the depth rod, loosen the side handle

4

and

move depth rod

6

so that the distance between the end

of the rod and the end of the bit equals the desired drilling

depth. When drilling with depth rod, stop when end of rod

reaches surface ofmaterial.

OPERATION

WARNING: To reduce the risk of serious personal

injury, turn unit off and disconnect it from

power source before making any adjustments or

removing/installing attachments or accessories.

An accidental start-up can causeinjury.

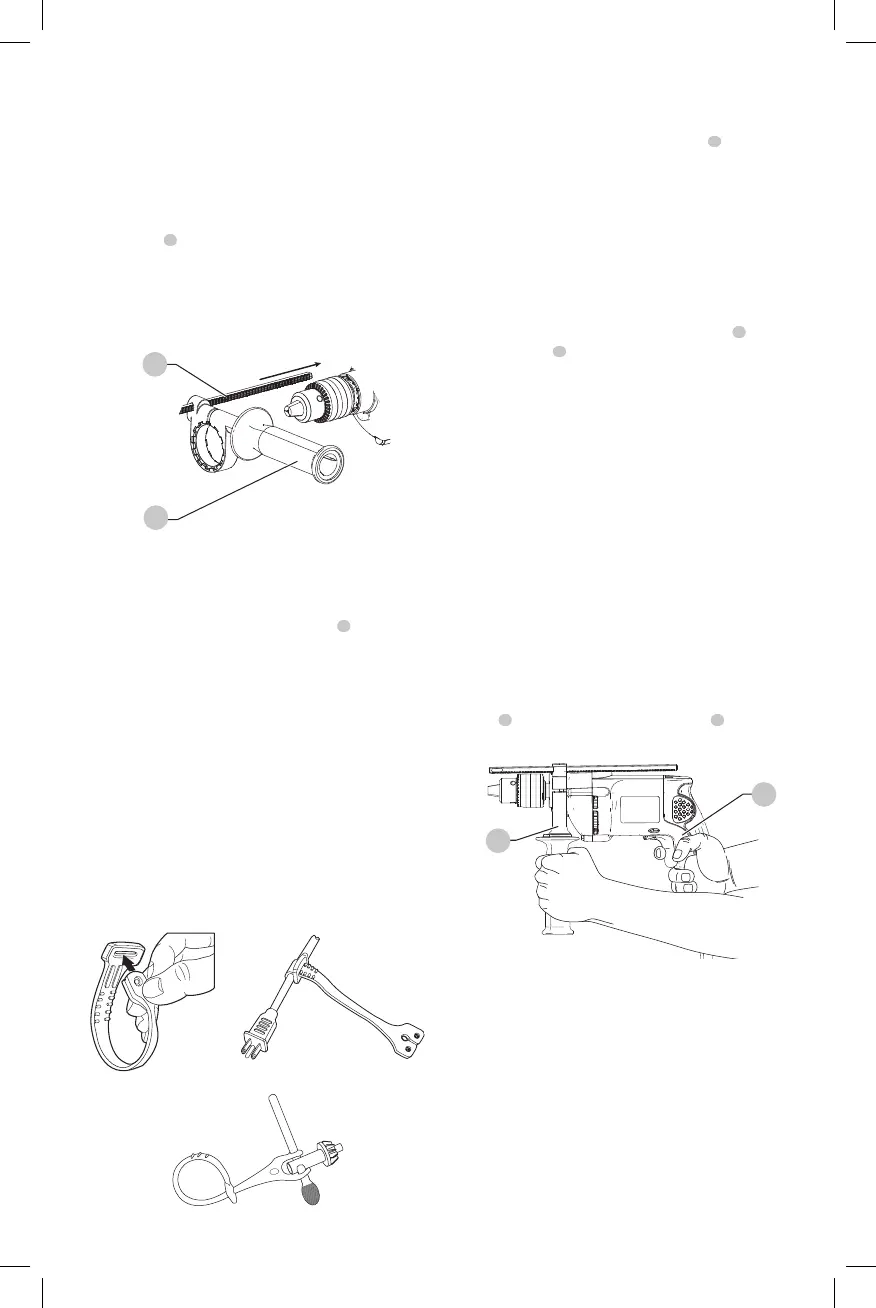

Proper Hand Position (Fig. G)

WARNING: To reduce the risk of serious personal injury,

ALWAYS use proper hand position as shown.

WARNING: To reduce the risk of serious personal

injury, ALWAYS hold securely in anticipation of a

suddenreaction.

Proper hand position requires one hand on the main

handle

8

and one hand on the side handle

4

.

Fig. G

8

4

WARNING: To reduce the risk of personal injury,

ALWAYS ensure workpiece is anchored or

clamped firmly. If drilling thin material, use a wood

“back-up” block to prevent damage to thematerial.

WARNING: To reduce the risk of personal injury,

ALWAYS operate the tool with the side handle

properly installed. Failure to do so may result in

the side handle slipping during tool operation and

subsequent loss of control. Hold tool with both hands

to maximizecontrol.

Loading...

Loading...