8

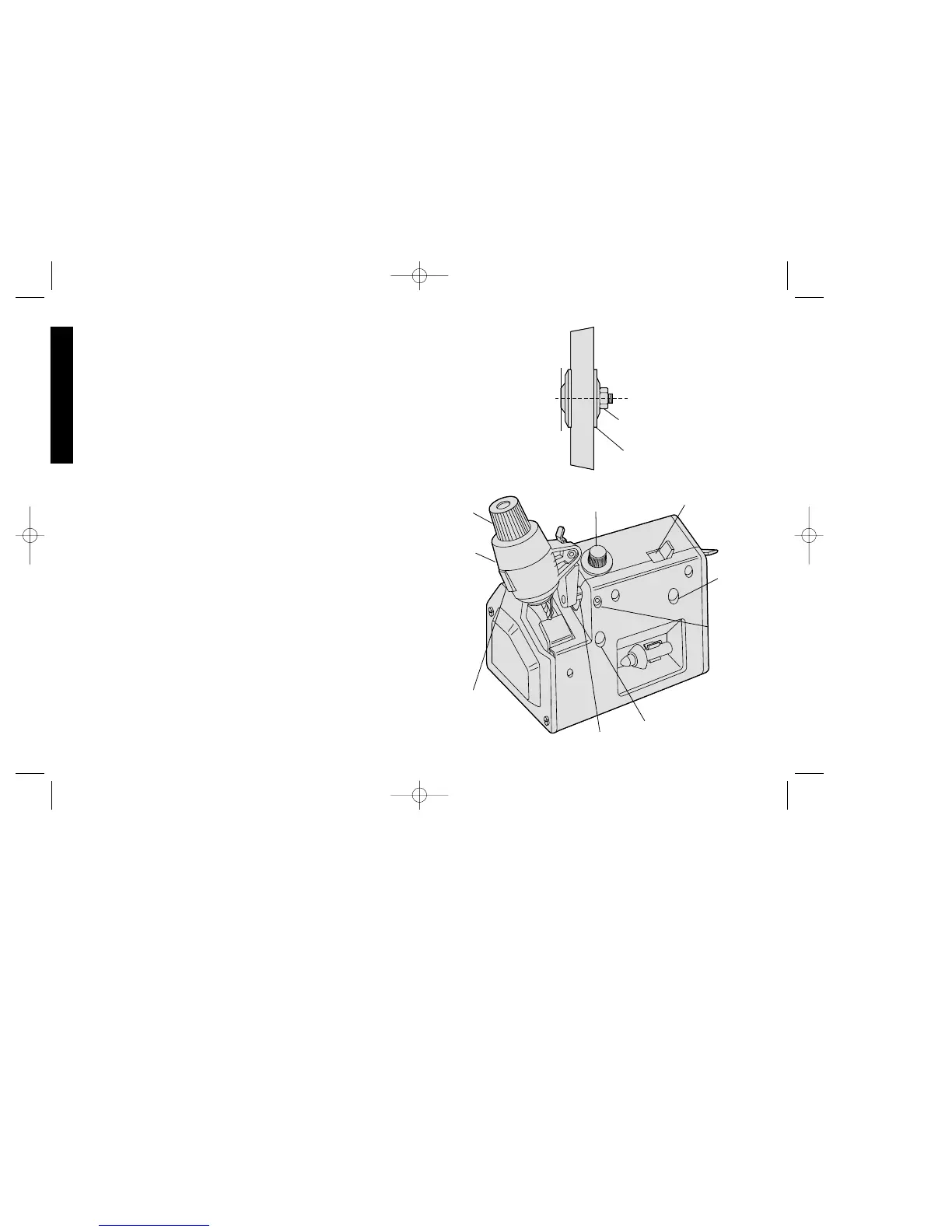

5. Attach new wheel (Fig. 24) (Note that the wheel is marked to show

which side faces out.) with clamp washer and spindle nut. Hold

wheel with a rag and tighten nut counterclockwise. Do not

overtighten.

6. Adjust guard band and finger guard to about 1/16" (1.6 mm) from

wheel (Fig. 27) and tighten adjusting screws.

7. Replace wheel cover.

8. For best results dress the new wheel with the diamond dresser.

Adjustments

FROM TIME TO TIME ADJUSTMENTS MAY BE NECESSARY DUE

TO WEAR OR SEVERE HANDLING OF THE UNIT DURING

SHIPMENT OR MOVEMENT FROM PLACE TO PLACE. SHOULD

ADJUSTMENTS BECOME NECESSARY, THE FOLLOWING

PROCEDURES SHOULD BE FOLLOWED CAREFULLY TO

INSURE PROPER AND SAFE OPERATION OF YOUR

SHARPENER.

UNPLUG TOOL BEFORE MAKING ANY ADJUSTMENTS.

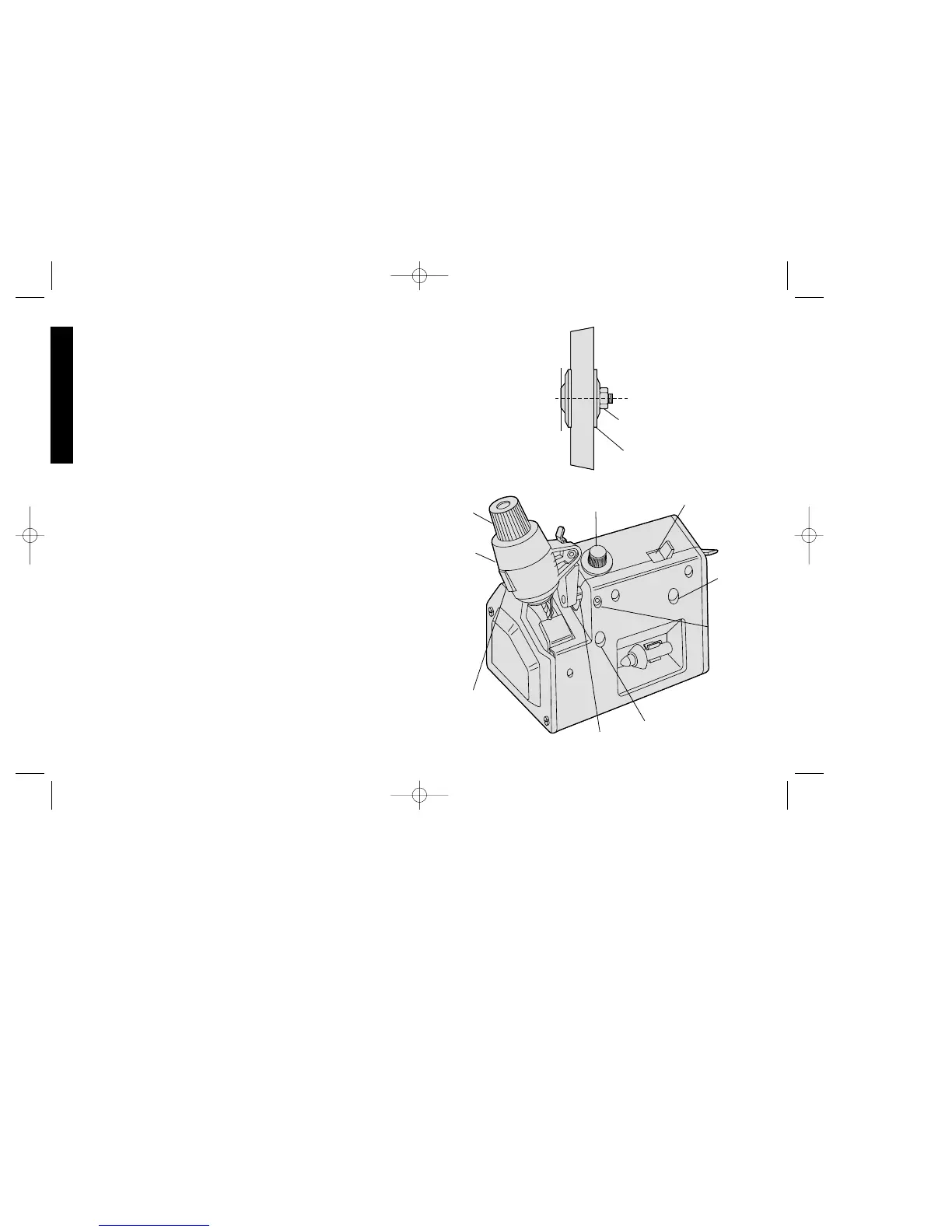

1. Looseness in Pivot Rod Bearing System (Fig. 25.)

A. Set selector lever to “S” (Sharpen).

B. Position swinghead with locator approximately 1/8” (3 mm)

above wheel.

C. Loosen both front bearing gib screws until slight side play in

pivot is evident.

D. While rocking swinghead, adjust back bearing gib screw until

very slight pivoting resistance is felt. Back off screw 1/8 to 1/4

turn.

E. Adjust front bearing top and bottom gib screws evenly, while

rocking swinghead, until slight pivoting resistance is felt.

2. Latch Adjustment (Fig. 26)

A. Move swinghead to sharpening position.

English

FIG. 24

SPINDLE

NUT

CLAMP

WASHER

CHUCK

KNOB

SHARPEN/DRESS

SELECTOR

BACK

BEARING

GIB

SCREW

FRONT

BEARING

GIB

SCREW

(TOP)

FRONT BEARING GIB

SCREW (BOTTOM)

PIVOT ROD

CHUCK

RETAINING

SCREW

SWING-

HEAD

FIG. 25

FEED KNOB

RETAINING SCREW

Loading...

Loading...