34

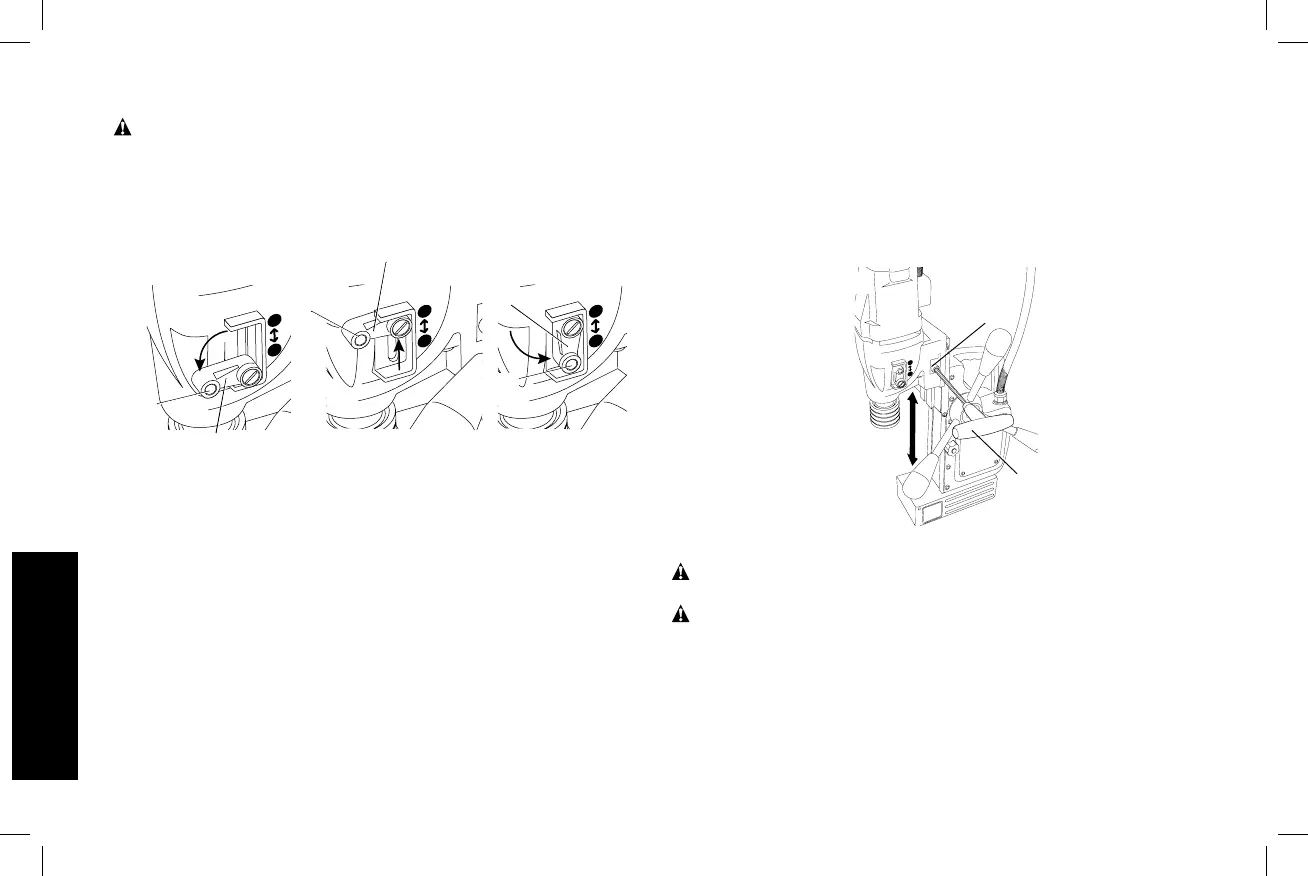

Setting the speed (fig. 8)

WARNING: Do not change gears at full speed or during use.

The machine is equipped with a two-gear selector to vary the speed/

torque ratio.

1. Rotate the gear selector tab (D) out of the detent slot and shift into

the desired mode.

2

1

FIG. 8

D

AA

y

AA

D

D

2. Lock the selector tab back into the detent.

LOW SPEED AND HIGH TORQUE: The yellow dot (AA) should

be aligned with position 1 for low speed and high torque (holes

from 32 to 50 mm).

HIGH SPEED AND LOW TORQUE: The yellow dot (AA) should

be aligned with position 2, for high speed and low torque (holes

from 12 to 30 mm).

NOTE : It may be necessary to slightly turn the spindle by hand a little

to complete the gear change.

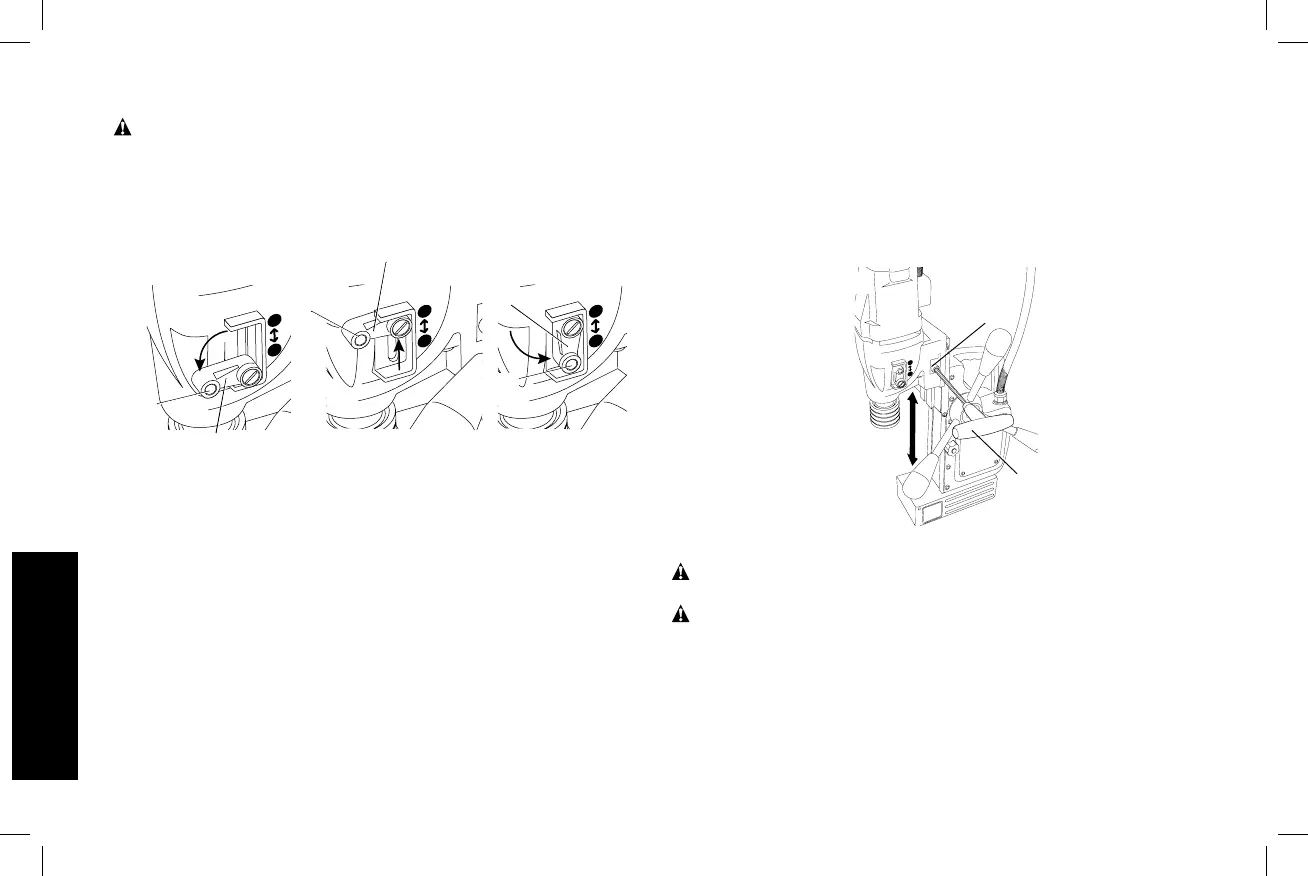

Adjusting the Motor Height (fig. 9)

The motor height can be adjusted to accommodate the need for

more or less bit clearance over the workpiece.

1. Loosen the motor slide bolt (BB) with the supplied hex key tool

(CC).

2. Position the motor to the desired height.

3. Tighten the bolt firmly with the hex tool to secure the motor in

position.

2

1

FIG. 9

CC

BB

OPERATION

WARNING: Alwaysobservethesafetyinstructionsandapplicable

regulations.

WARNING: To reduce the risk of injury, turn unit off and

disconnect tool from power source before installing and

removing accessories, before making any adjustments or

removing/installing attachments or accessories. Anaccidental

start-upcancauseinjury.

• Apply only a gentle pressure to the tool. Excessive force

does not speed up drilling but decreases tool performance

and may shorten tool life.

Loading...

Loading...