ENGLISH

24

...................... Class II

Construction

(double insulated)

n

o

........................no load speed

n .........................rated speed

......................earthing terminal

.....................safety alert symbol

.....................visible radiation

..................... wear respiratory

protection

..................... wear eye

protection

..................... wear hearing

protection

SAVE THESE INSTRUCTIONS FOR

FUTURE USE

Motor

Be sure your power supply agrees with the nameplate

marking. Voltage decrease of more than 10% will cause loss

of power and overheating.

tools are factory tested;

if this tool does not operate, check powersupply.

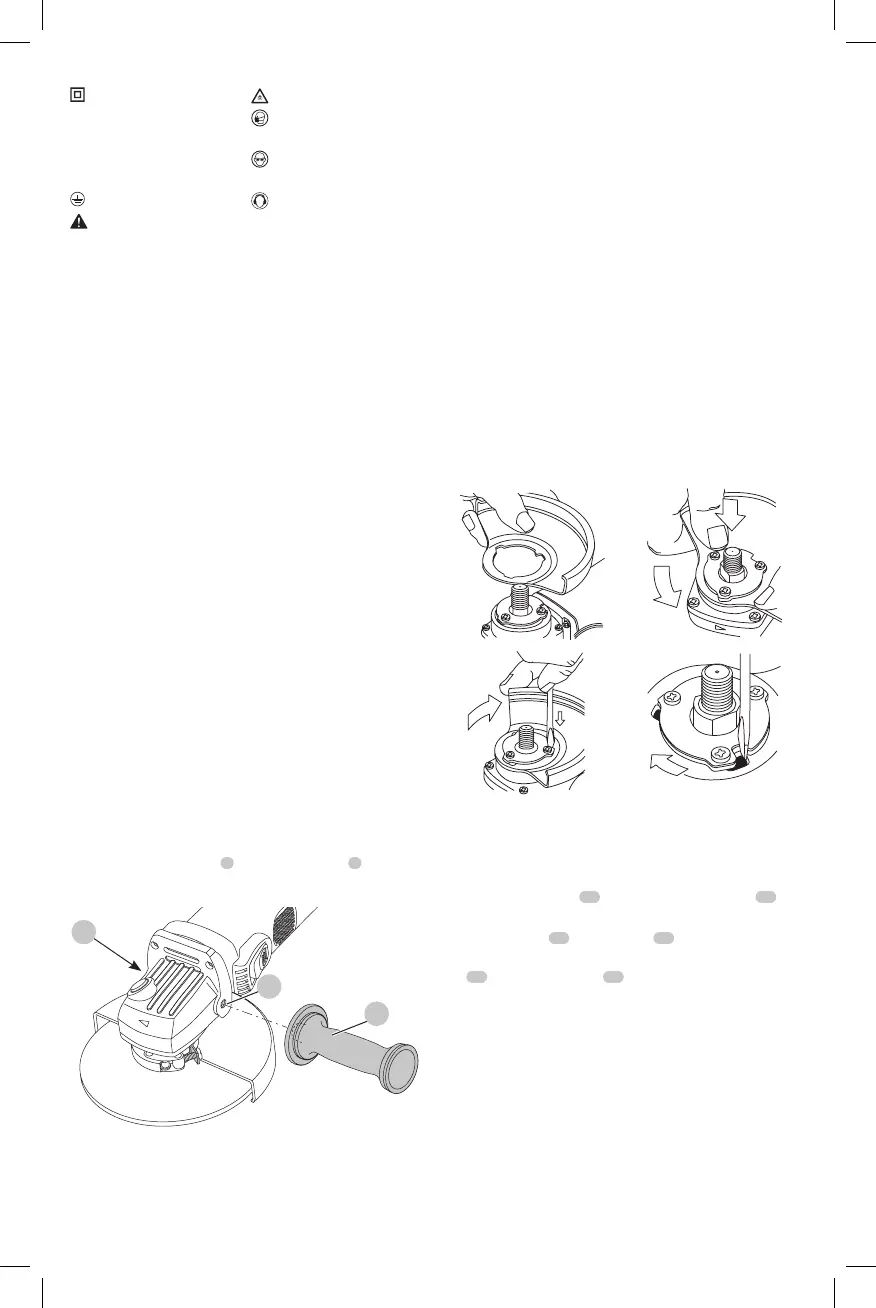

COMPONENTS (FIG. A)

WARNING: Never modify the power tool or any part

of it. Damage or personal injury couldresult.

Refer to Figure A at the beginning of this manual for a

complete list ofcomponents.

INTENDED USE

This grinder is designed for professional grinder, sander,

wire brush or cut-offapplications.

DO NOT use under wet conditions or in presence of

flammable liquids orgases.

This grinder is a professional power tool. DO NOT let

children come into contact with the tool. Supervision is

required when inexperienced operators use thistool.

ASSEMBLY AND ADJUSTMENTS

WARNING: To reduce the risk of serious personal

injury, turn unit off and disconnect it from

power source before making any adjustments or

removing/installing attachments or accessories.

An accidental start-up can causeinjury.

Fitting the Side Handle (Fig. B)

Tightly screw side handle

4

in one of the holes

5

of either

side of thegearbox.

Fig. B

5

5

4

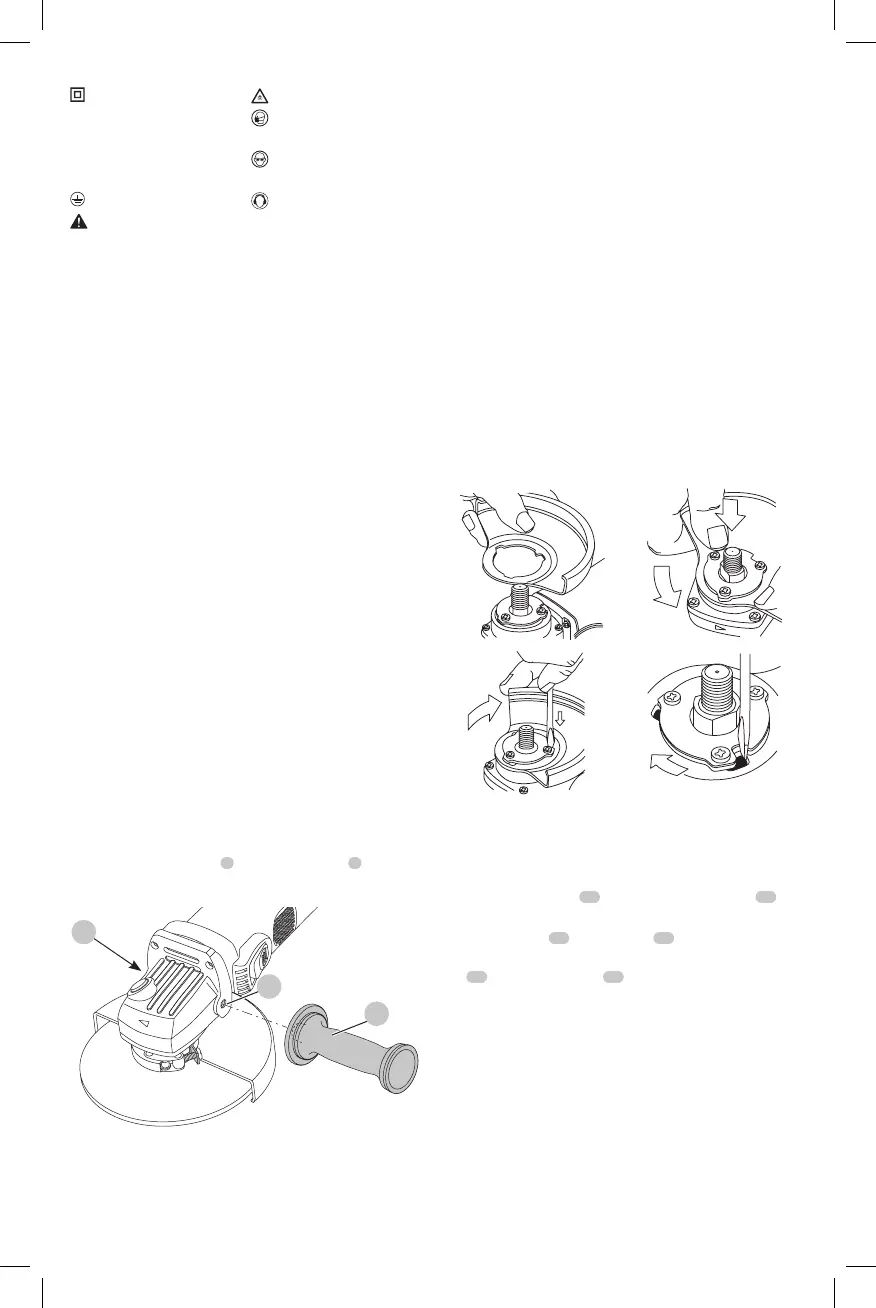

Mounting and Removing the Guard

(Fig. C)

1. Align the lug on the guard with the slot in the bracket

fixed to the base of the gear case (Fig. C1).

2. Press the guard down toward the gear case, and then

rotate the guard in the direction of the arrow (Fig. C2).

3. In this position, the guard locking pin located in the

slot prevents the guard from coming loose, but allows

rotation through 105°.

To remove the guard

1. Place the tool upside down on a flatsurface.

2. Hold the tool, and using your thumb, rotate the guard

in the direction of the arrow (Fig. C3). At the same

time, using a screwdriver or other pointed instrument,

press the locking pin in the slot so the lug on the guard

comes into view (Fig. C4).

3. The locking pin does not hold the guard, and the guard

can be pushedfree.

2

Fig. C

Fitting and Removing a Grinding Disc

(Fig. A, D–E)

1. Place the tool on a table, guardup.

2. Fit the inner flange

10

correctly onto the spindle

11

(Fig.D).

3. Place the disc

12

on the flange

10

. When fitting a disc

with a raised center, make sure that the raised center

13

is facing the flange

10

.

Loading...

Loading...