ENGLISH

25

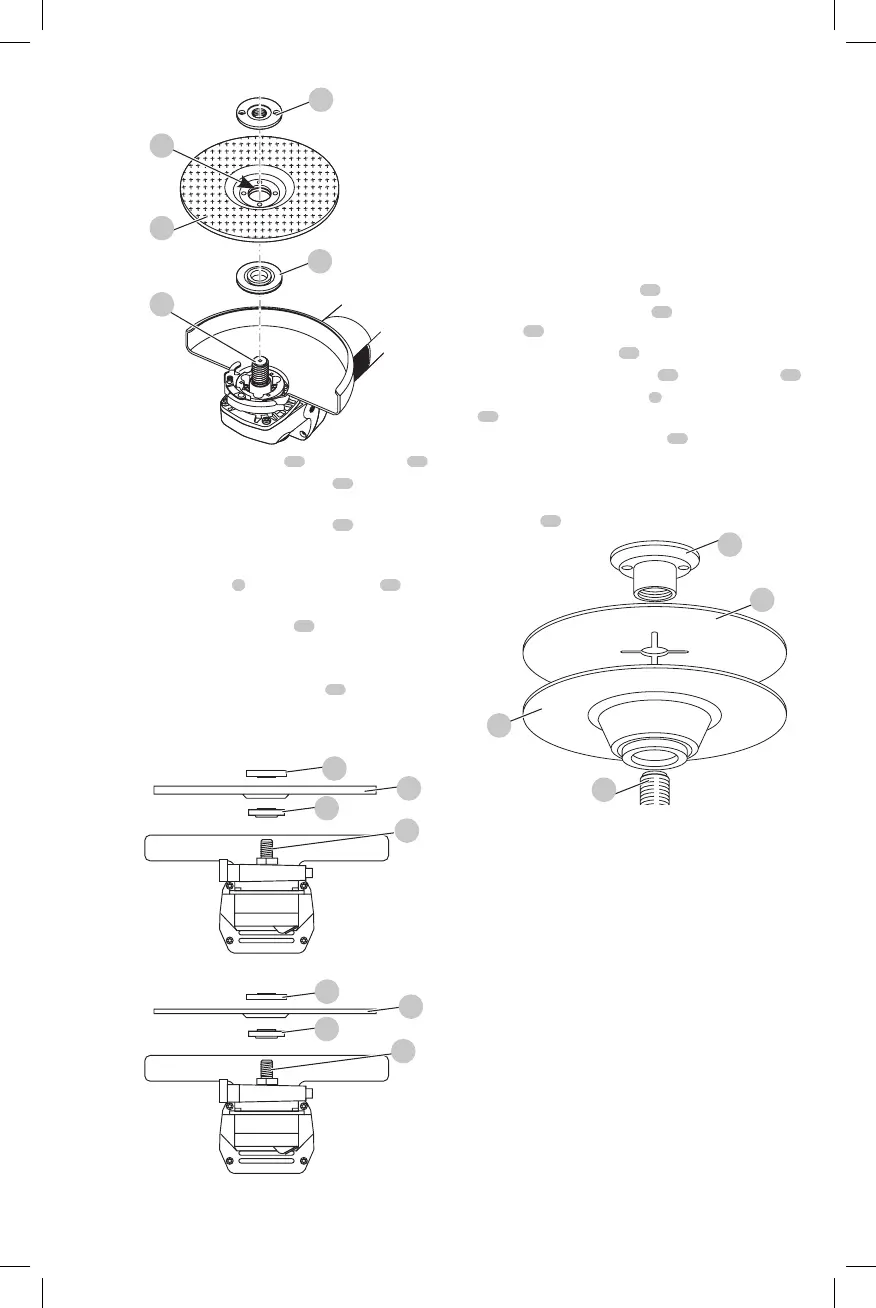

Fig. D

14

13

12

11

10

4. Screw the threaded clamp nut

14

onto the spindle

11

a. The ring on the threaded clamp nut

14

must face

towards the disc when fitting a grinding disc (Fig. E1);

b. The ring on the threaded clamp nut

14

must

face away from the disc when fitting a cutting

disc(Fig.E2).

5. Press the spindle lock

2

and rotate the spindle

11

until

it locks inposition.

6. Tighten the threaded clamp nut

14

with the two-pin

spannersupplied.

7. Release the spindlelock.

8. To remove the disc, loosen the flange

14

with the two-

pinspanner.

WARNING: Do not use a damageddisc.

Fig. E1

Fig. E2

14

12

10

14

12

10

11

11

Fitting a Wire Cup Brush

Screw the wire cup brush directly onto the spindle without

the use of the spacer and threadedflange.

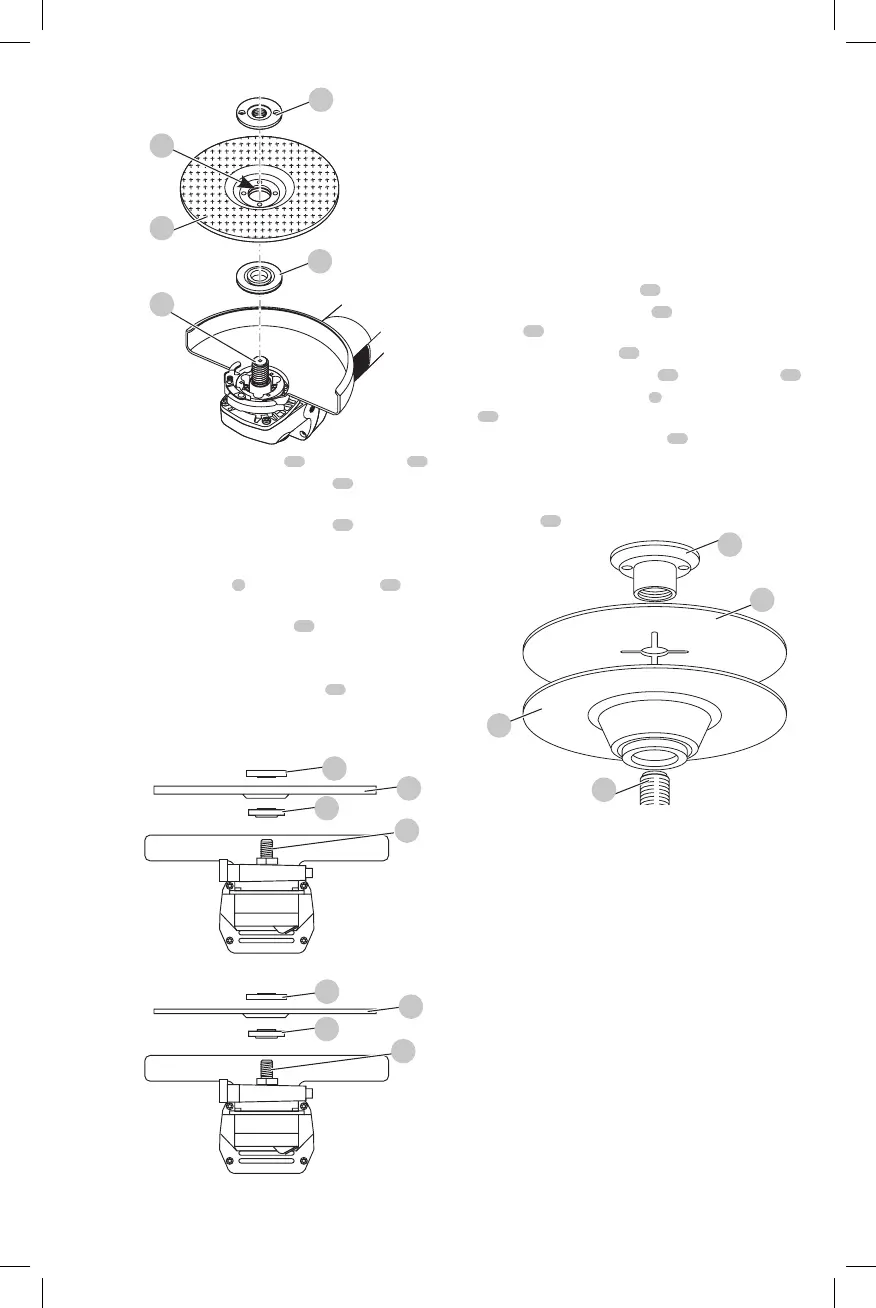

Fitting and Removing a Backing

Pad/Sanding Sheet (Fig. A, D, F)

The backing pad is available at extra cost from your local

dealer or authorized servicecenter.

1. Remove the guard from thetool.

2. Remove the backing flange

10

.

3. Place the rubber backing pad

15

correctly onto the

spindle

11

.

4. Place the sanding sheet

16

on the rubber backingpad.

5. Screw the threaded clamp nut

17

onto the spindle

11

.

6. Press the spindle lock button

2

and rotate the spindle

11

until it locks inposition.

7. Tighten the threaded clamp nut

17

with the two-

pinspanner.

8. Release the spindle lock

9. To remove the rubber backing pad, loosen the threaded

clamp nut

17

wih the two-pinspanner.

Fig. F

17

16

15

11

OPERATION

WARNING: Always observe the safety instructions

and applicableregulations.

• Ensure all materials to be ground are secured

inplace.

• Apply only a gentle pressure to the tool. Do not

exert side pressure on thedisc.

• Avoid overloading. Should the tool become hot,

let it run a few minutes under no load condition to

cool theaccessory.

WARNING: To reduce the risk of serious personal

injury, turn unit off and disconnect it from

power source before making any adjustments or

removing/installing attachments or accessories.

An accidental start-up can causeinjury.

Loading...

Loading...