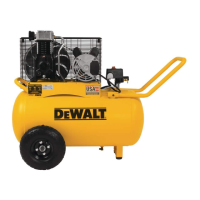

This document describes the DEWALT DXCMLA1682066 Single Stage, Belt Drive, Electric Air Compressor, an air compressor designed for various applications requiring compressed air.

Function Description:

The DEWALT DXCMLA1682066 is an electric air compressor that compresses ambient air and stores it in an air tank for later use. It features a two-cylinder, single-stage, oil-lubricated pump that automatically starts when the air tank pressure drops below a factory-set cut-in pressure and stops when it reaches the factory-set cut-out pressure. The compressed air is then regulated to a desired pressure for use with air tools, spray guns, and other air-operated accessories. A safety valve is incorporated to prevent over-pressurization, and an air tank drain valve allows for the removal of condensed water, which is crucial for preventing internal corrosion and maintaining tank integrity. The unit is designed for stationary use but can be transported, with specific instructions provided to prevent oil leaks and damage during transit.

Important Technical Specifications:

- Model: DXCMLA1682066

- Pump Type: 2 Cylinder, Single Stage, Oil Lubricated

- Pump Construction: Cast iron crankcase, cylinder, and aluminum head

- Pump Weight: 30.5 lbs (13.8 kg)

- Oil Capacity: 11.35 oz. (336 mL)

- Overall Weight: 159 lbs (72 kg)

- Height: 50.12"

- Width: 24.12"

- Air Tank Capacity: 20 gallons (75.7 liters)

- Approx. Blow Off Pressure: 175 psi

- Electrical Requirements: Operates on a dedicated 15 or 20 amp circuit, depending on conditions. Requires a 3-wire extension cord (12 AWG or larger, no longer than 50 feet) if used.

- Safety Features: Safety valve, thermal motor overload protector, warning labels for hot surfaces, moving parts, electrical shock, bursting, explosion/fire, breathing hazards, and unsafe operation.

Usage Features:

The compressor is equipped with several controls and indicators for ease of use:

- Auto(-)/Off(O) Switch (B): Allows for automatic operation (starts and stops based on tank pressure) or manual shutdown. It is crucial to set this to OFF(O) before any maintenance or when not in use.

- Air Tank Pressure Gauge (C): Displays the reserve air pressure inside the tank.

- Regulated Pressure Gauge (D): Shows the air pressure available at the outlet after regulation.

- Pressure Regulator (E): A knob that adjusts the output air pressure. Turning clockwise increases pressure, counter-clockwise decreases it.

- Air Outlet (F): The point where regulated compressed air is delivered.

- Safety Valve (G): A critical safety device that releases pressure if it exceeds a predetermined level. It must be checked for free operation before each use.

- Air Tank Drain Valve (H): Located at the base of the air tank, used to drain condensed water.

- Pump Oil Fill Plug (I) and Drain Plug (J): For adding and draining pump oil.

- Check Valve (K): Allows compressed air into the tank and closes when the compressor reaches cut-out pressure, preventing air from flowing back to the pump.

- Quick Connect (L): A universal body that accepts common quick connect plugs (Industrial, Automotive, ARO) for easy hose attachment.

- Motor Overload Protector (N): A red reset button that activates if the motor overheats, shutting down the unit. The motor must cool down before restarting.

Break-in Procedure: Before initial use or after replacing the check valve or pump, a 30-minute break-in period is required. This involves running the compressor with the drain valve fully open to prevent pressure build-up, ensuring minimal air pressure in the tank. This procedure is vital to prevent property damage and ensure proper pump function.

Maintenance Features:

Regular maintenance is essential for efficient operation and longevity of the air compressor. A detailed maintenance chart outlines daily, weekly, monthly, yearly, and "after first 20 hours" procedures.

- Daily Maintenance:

- Check safety valve for free operation.

- Drain condensed water from the air tank.

- Check pump oil level.

- Weekly Maintenance:

- Inspect air filter (more frequently in dusty/humid conditions).

- Inspect drive belt.

- Check for unusual noise/vibration.

- Check for air leaks using soapy water solution.

- Clean compressor exterior.

- Monthly Maintenance:

- Inspect drive belt tension.

- Check pulley/flywheel alignment.

- Yearly Maintenance (or every 100 hours of operation, whichever comes first):

- Change pump oil (after the first 20 hours, then yearly/100 hours). Use synthetic blend non-detergent air compressor oil only.

- Inspect air compressor pump intake and exhaust valves (by a Trained Service Technician).

- Check torque of air compressor pump head bolts (after first five hours of operation, then periodically).

- As Needed:

- Replace air filter elements if dirty.

- Address oil leaks.

- Clean or replace the check valve if it's stuck or not operating smoothly.

- Adjust belt tension and pulley/flywheel alignment if necessary.

- Relocate the compressor to a well-ventilated, cool, dry area if overheating occurs.

- Clean all cooling surfaces thoroughly.

Safety Precautions: The manual emphasizes numerous safety warnings, including risks of hot surfaces, moving parts, electrical shock, bursting (air tank, attachments), explosion/fire (flammable vapors, sparks), and breathing hazards (compressed air is not safe for human consumption). Users are instructed to wear certified safety equipment (eye and hearing protection), ensure proper grounding, and never operate the unit with damaged or removed guards. The compressor is heavy and requires assistance for lifting.

Loading...

Loading...