22

English

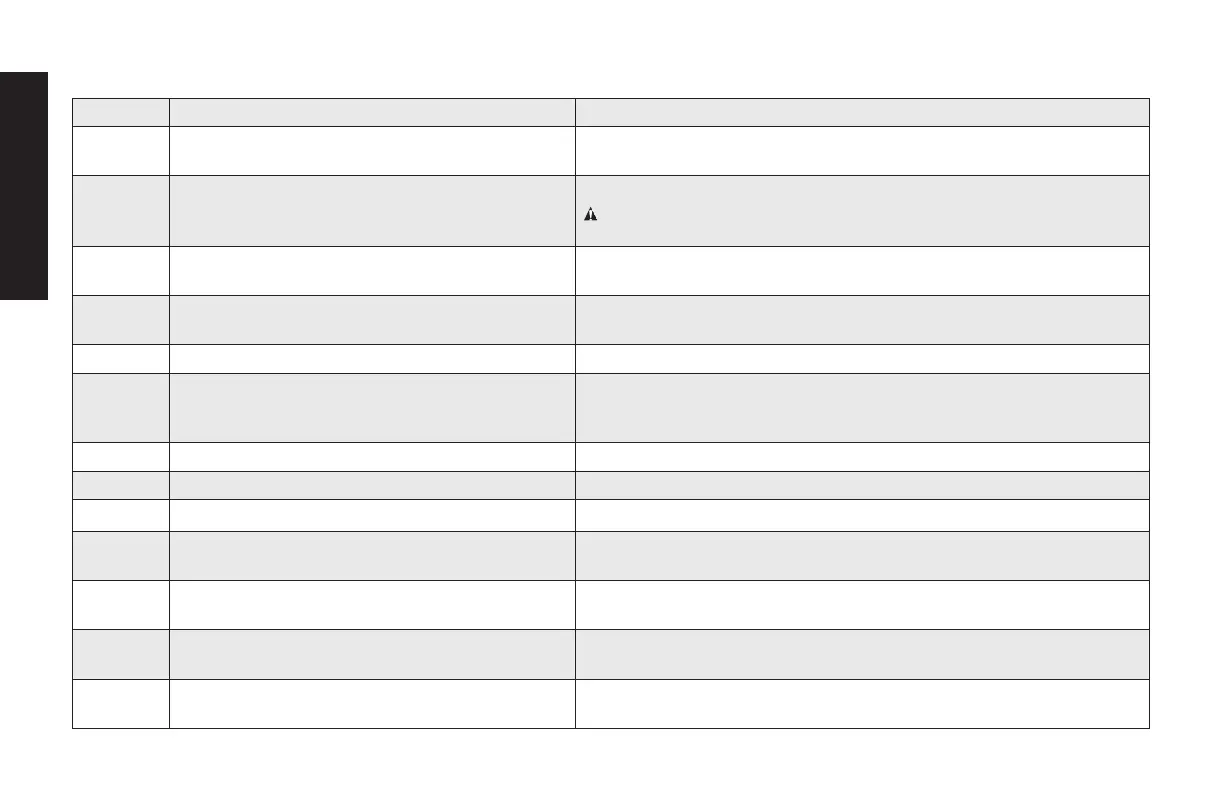

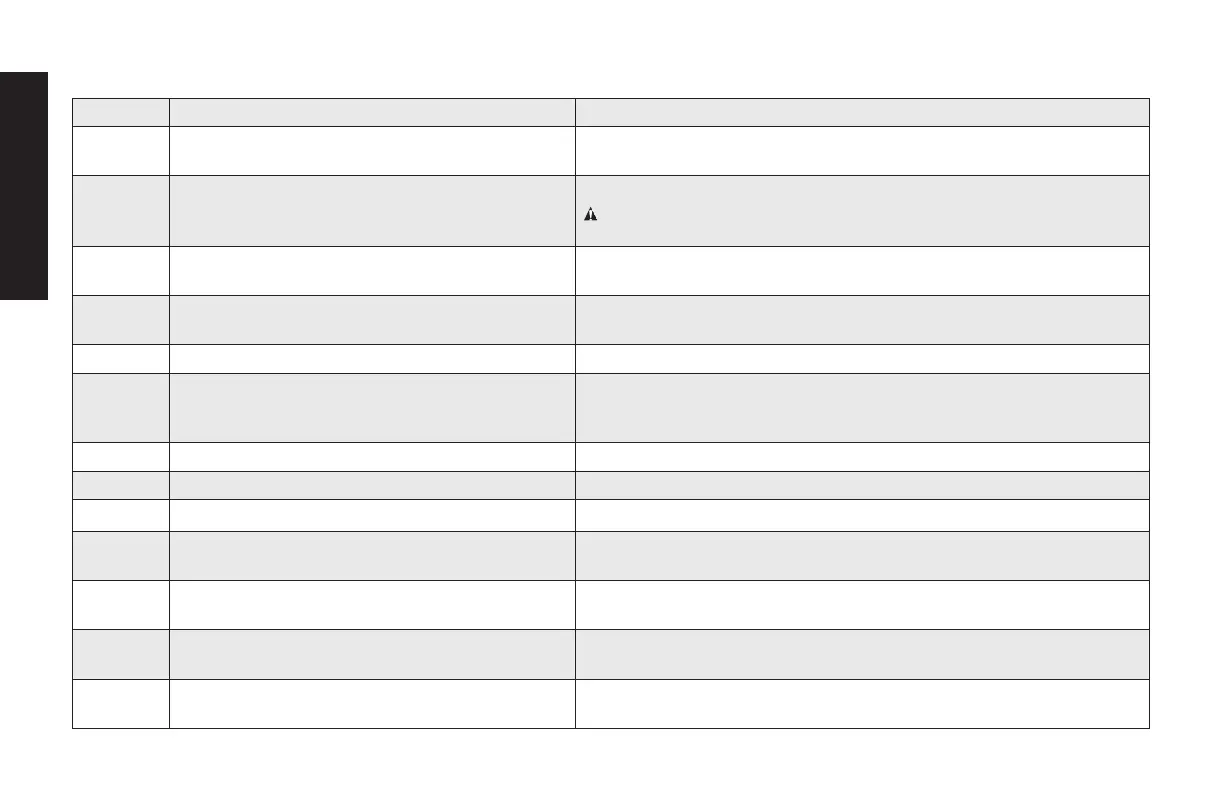

Troubleshooting Codes

CODE POSSIBLE CAUSE POSSIBLE SOLUTION

1 Fittings are not tight Tighten fittings where air can be heard escaping. Check fittings with

soapy water solution. DO NOT OVERTIGHTEN.

2 Defective air tank Air tank must be replaced. Do not repair the leak.

WARNING: Risk of bursting. Do not drill into, weld or otherwise

modify air tank or it will weaken. The air tank can rupture or explode.

3 Leaking seals Contact a D

eWALT factory service center or a D

e

WALT authorized ser-

vice center.

4 Defective safety valve Operate safety valve manually by pulling on ring. If valve still leaks, it

must be replaced.

5 Prolonged excessive use of air Decrease amount of air usage.

6 Compressor is not large enough for accessory Check the accessory air requirement. If it is higher than the SCFM

or pressure supplied by your air compressor, a larger compressor is

needed to operate accessory.

7 Hole in air hose Check and replace air hose, if required.

8 Unit operating in damp or humid conditions Move unit to a dry well ventilated area.

9 Restricted air intake filter Clean or replace air intake filter.

10

Extremely light duty cycles Run unit for longer duty cycles. It is recommended to run at high throttle

50-75% of the run time and idle for 25% of the run time.

11

Piston rings damaged or worn Contact a D

e

WALT factory service center or a D

e

WALT authorized

service center.

12

Cylinder or piston damaged or worn Contact a D

e

WALT factory service center or a D

e

WALT authorized

service center.

13

Compressor cylinder finish worn Contact a DeWALT factory service center or a D

e

WALT authorized

service center.

Loading...

Loading...