HI, MI, WI-700 service manual - 6 – maintenance schedule

6-4 Issue 9 04/2020

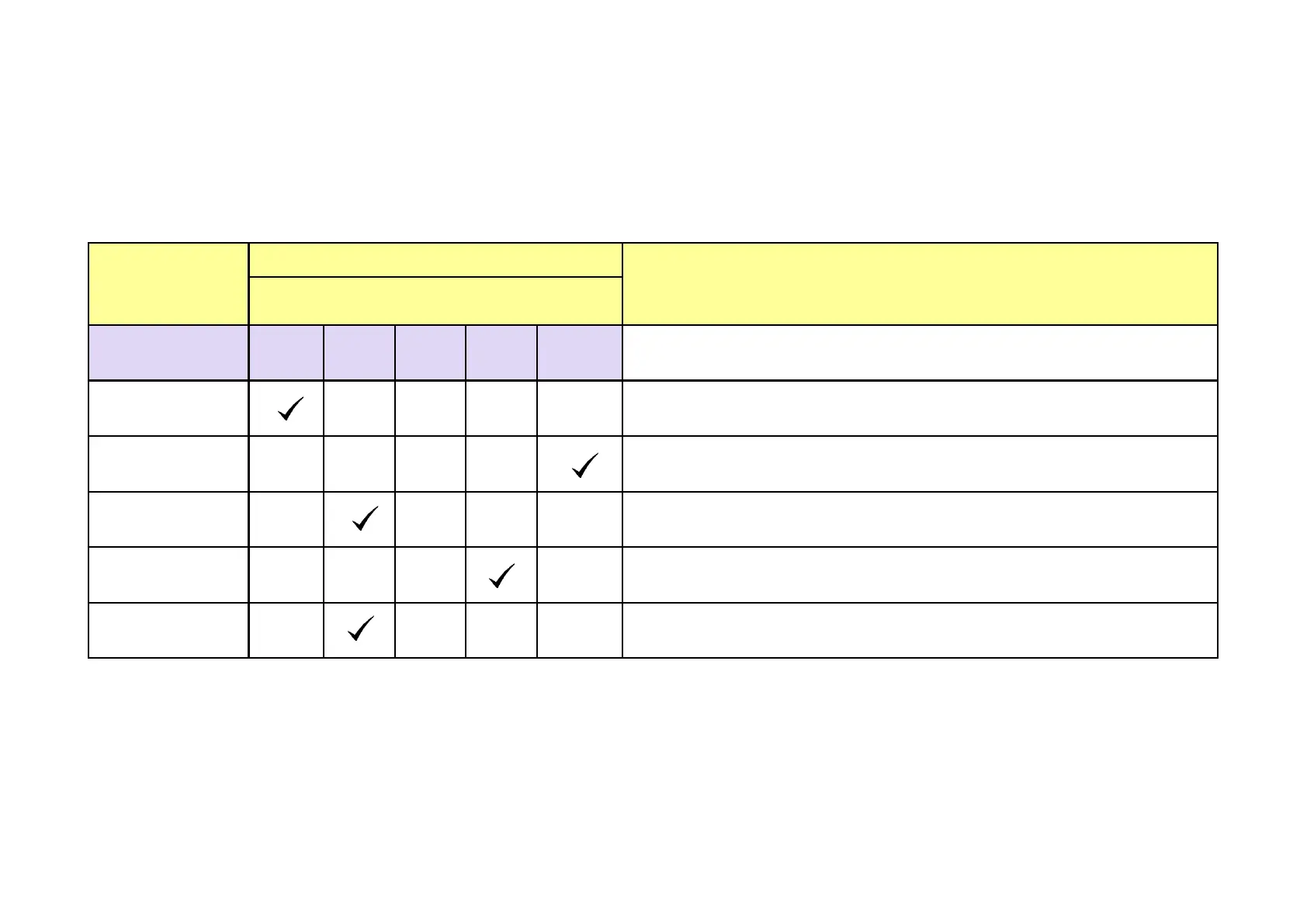

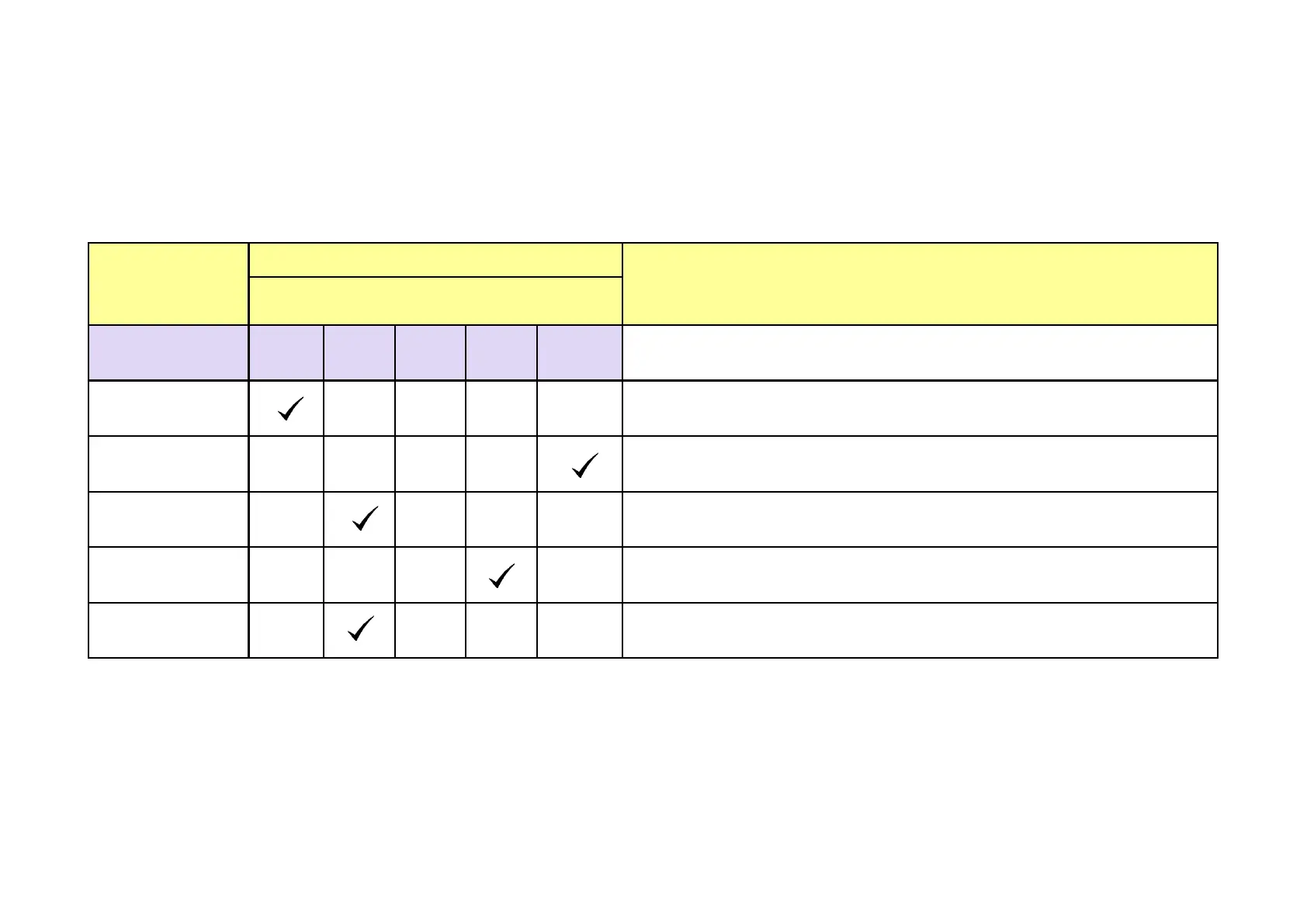

700 SERIES MACHINE ROUTINE MAINTENANCE SCHEDULE

Note: based on a 16-hour day. Daily & yearly checks to be carried out regardless of actual running time.

Weekly, monthly & 3 monthly intervals may be adjusted to suit actual machine running time.

MACHINE AREA /

COMPONENT

FREQUENCY OF TASK

DETAILS OF TASK

3

DAILY WEEKLY MONTHLY MONTHLY YEARLY

SCALE

WEIGHT CHECK Production on-line weight check

SCALE

CALIBRATION

Full scale calibration check – carry out complete weight check on scale. *SEE

NOTE BELOW

(Refer to service manual, servicing section)

LOAD CELL Check for debris on / around load cell area, clean. Re-zero if required.

Check mounting bolts are tight.

LIMIT STOPS

Check there is no debris between stop and scale frame, check limit stop distance is

set correctly. (Refer parts manual for scale base detail)

SCALE

ALIGNMENT

Check scale is secure and there is no movement in scale feet.

Check the scale frame / conveyor is not touching any other framework or infeed

conveyor.

* NOTE: This operation to be undertaken by the distributor or other qualified persons using traceable calibrated weights.

Loading...

Loading...