OPERATOR’S MANUAL with Maintenance Information

Maintenance

53

B-11

Lubrication

Dingli requires that this procedure be

performed every 250 hours or quarterly,

whichever comes first.

Good lubrication is essential to machine

performance and service life. Failure to

lubricate may cause the machine to perform

poorly and continued use may cause

component damage.

Lubrication involves:

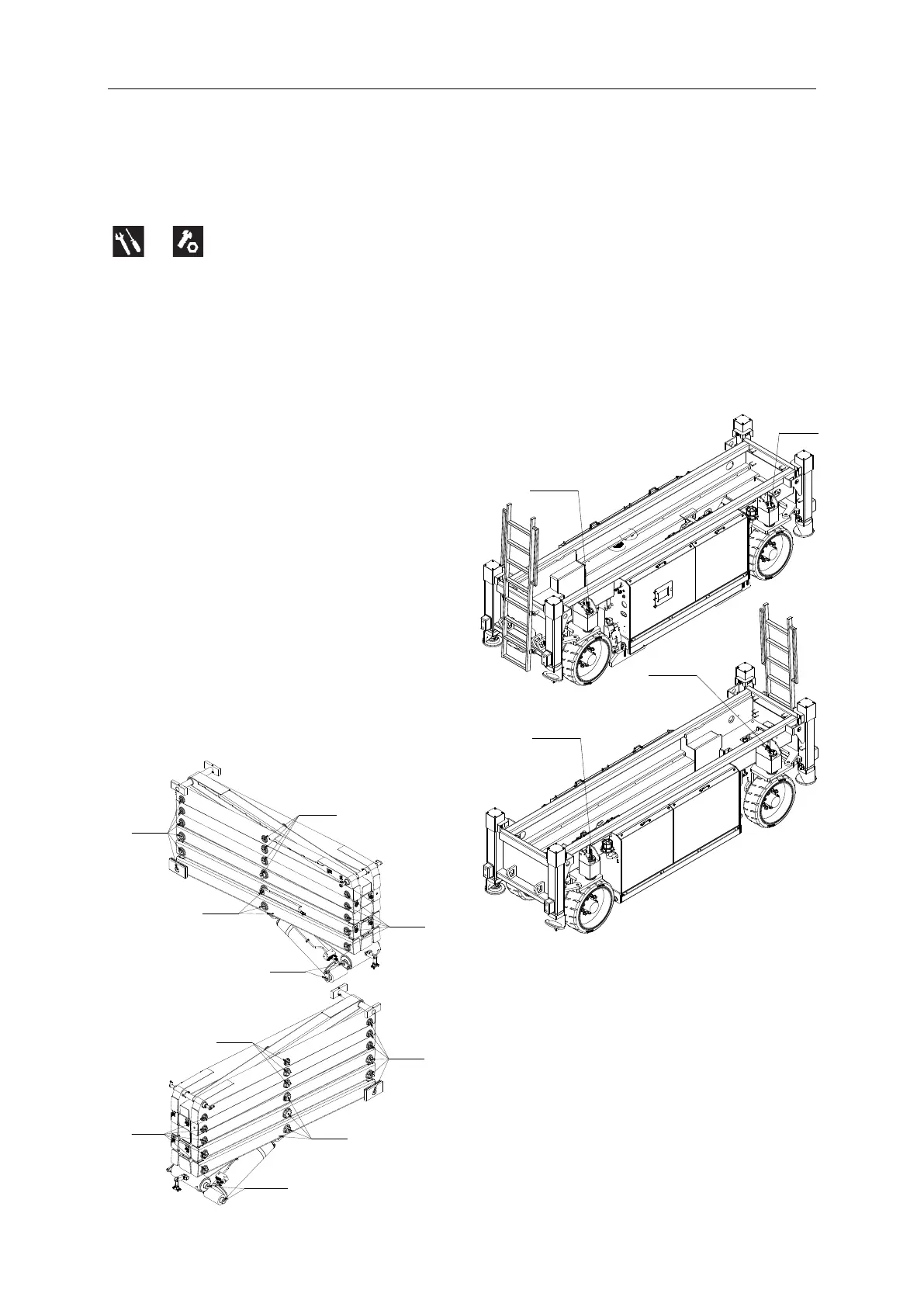

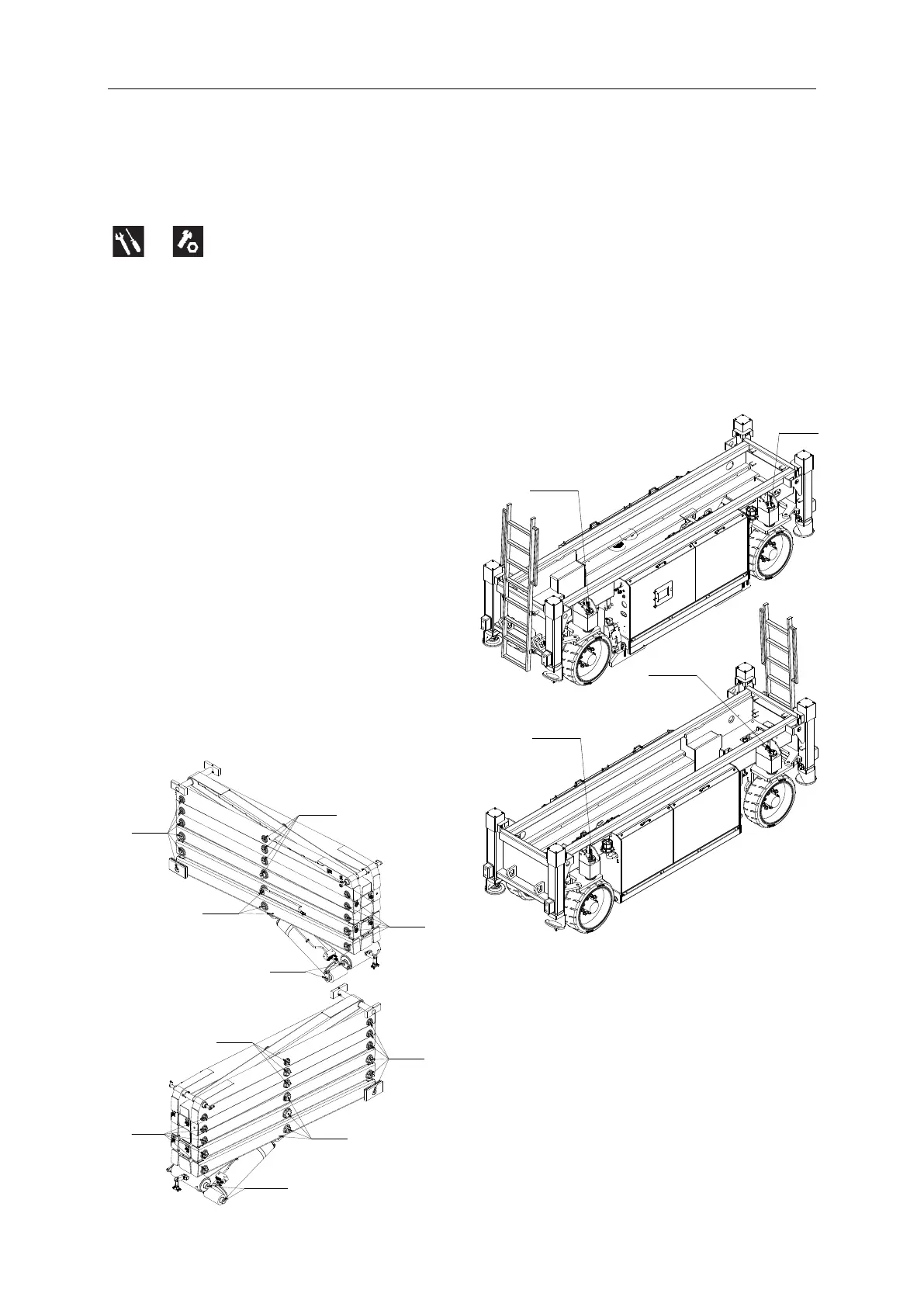

• The lubricating points on the scissor joints

• The lubricating points on the chassis.

• The lubricating points on the platform

The following points must be lubricated on

the scissor joint in particular:

• Scissor shaft

• Sliding blocks

• lifting cylinder

The following points must be lubricated on

the chassis in particular:

• Steering

• Sliding tracks of the sliding blocks

The following points must be lubricated on

the platform in particular:

• Sliding blocks - sliding tracks

• Guide rollers of the platform extension

Grease

nipple

Grease

nipple

Grease

nipple

Grease

nipple

Grease

nipple

Grease

nipple

Grease

nipple

Grease

nipple

Grease

nipple

Grease

nipple

Grease

nipple

Grease

nipple

Grease

nipple

Grease

nipple

Loading...

Loading...