13

I25 I24 I23 I22 I21 I20 I19 I18 I17 I16 sv fr en de

Service, maintenance and care

Maintenance of the machine is a pre-condition for trouble-free running and a

long life.

Service intervals

TASKI machines are built to the highest quality standards, and their safety is

tested in the factory and by authorised inspectors. Electrical and mechanical

parts are subject to wear or aging if used for long periods of time.

Service centre

Should you contact us due to a malfunction or for placing an order, please

always state the type, description and the serial number of your machine.

You can find this information on the name plate of your machine, and the

address of your nearest TASKI partner can be found on the last page of this

manual.

Malfunctions

Transport

Lifting the machine

Ensure that the machine is firmly lashed down and secured in the transport

vehicle.

Disposal

When they are no longer serviceable, the machine and its accessories must be

disposed off in a professional manner in accordance with the national

regulations. Your TASKI partner can help you here on request.

Technical data

Accessories

Caution:

Always unplug the mains plug from the main socket when carrying

out any maintenance work!

Caution:

Only TASKI branded spare parts must be used, otherwise

warranties and liabilities will be omitted!

Symbols:

= after use, = every week, = every month

Activity page

Check the motor ventilation for the collection of

dust and clean when necessary

10

Check/change the dust bag

12

Clean the pads and let them dry

12

Clean the machine with a damp cloth

12

• In order to maintain operational reliability and availability for use, the service

must be carried out after 250 working hours or at least once a year.

Shorter interval may be necessary under rough or extreme working

conditions and / or insufficient maintenance.

Malfunction Possible causes Troubleshooting page

Machine does not

work

No power supply

• Connect the power

supply cord to the

mains socket

11

The foot pedal is not

unlatched.

• Unlatch the foot pedal.

11

Safety switch defect

• Contact your Service

partner

Machine cannot

be operated, but

the switch is on

Machine has

overheated causing

motor protection

switch (trip) to cut in.

• Wait a while, try again

(the protection switch

will automatically

reset)

Pad does not

rotate

Motor runs, but not

the tool

• Drive belt is torn or

lose

• Contact your service

partner

Electrical component

defective.

• Contact your service

partner

Machine does not

reach rated

speed, motor

protection cuts in

Machine is

overloaded

• Check if you are using

the correct working

technique

11

Insufficient voltage,

power cord is too long

• Remove extention

• Check power supply

voltage

Machine runs

uneasy

Pad is deformed or

damaged

• Replace pad

11

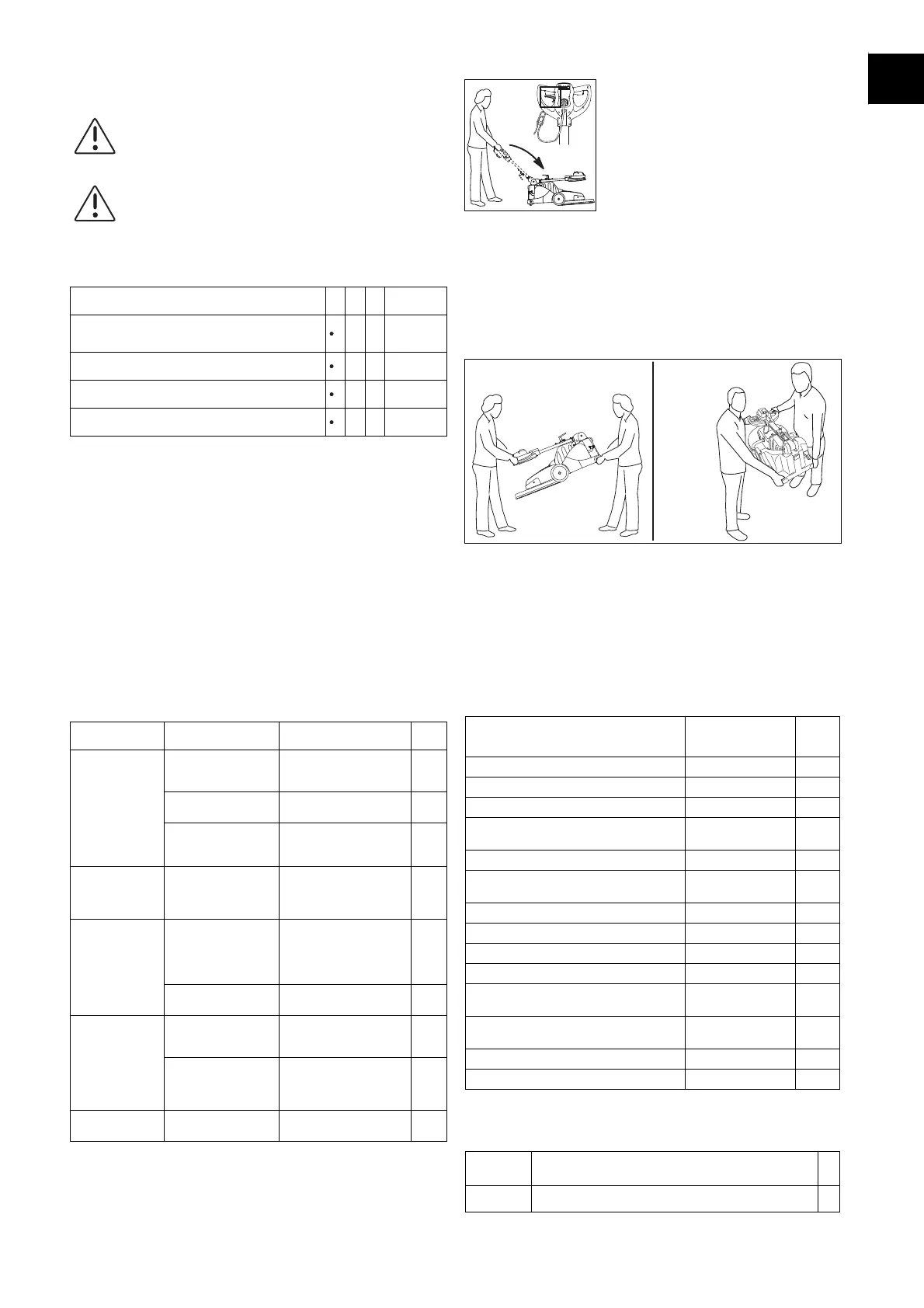

• Bring the machine into the transport position.

The foot pedal must be latched in.

Option A: To lift the machine, hold the machine by the handle while a

second person holds the back of the housing.

Option B: To lift the machine, both persons should hold the machine by

the handle and the back of the housing.

Machine 2000

type 2000HSP

Working width 50 cm

Dimensions (L x W x H) 108x59x119 cm

Machine weight 54 kg

Rated voltage 220-240V

100-120V

AC

AC

Rated power 1500 W

Frequency 50

60

Hz

Hz

Power supply cord length 25 m

Pad rotation speed 2000 min-1

Pad pressure 0.045 N/cm2

Max. pad thickness 30 mm

Assessed sound level LPA according to

ISO 11201

70 dB(A)

The assessed effective acceleration value

according to ISO 5349-1

<2.5 m /s2

Splash water protection IPX0

Electrical protection class I

Article

2000

7521297 Disposable dust bag X

A

Loading...

Loading...