5-5 TAPE

SPEED

a.

Specif

ication

19

cm/sec

(l'112

iPsl

!1-5%

(2955

3

KHz

test

tape).

9.5 cm/sec

(3-3/4

iPs)

!1.5%

(2955

3

KHz

test

tape).

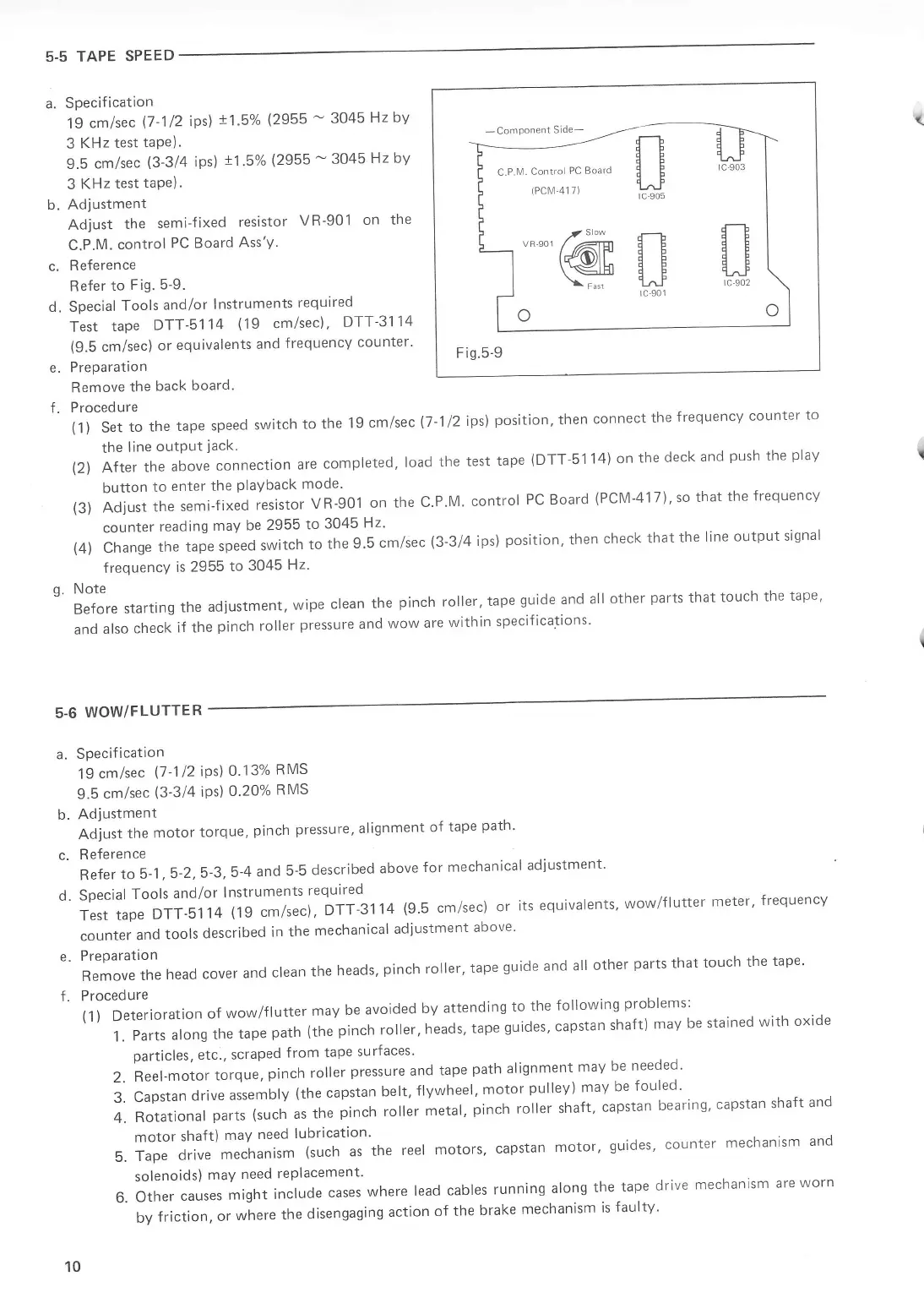

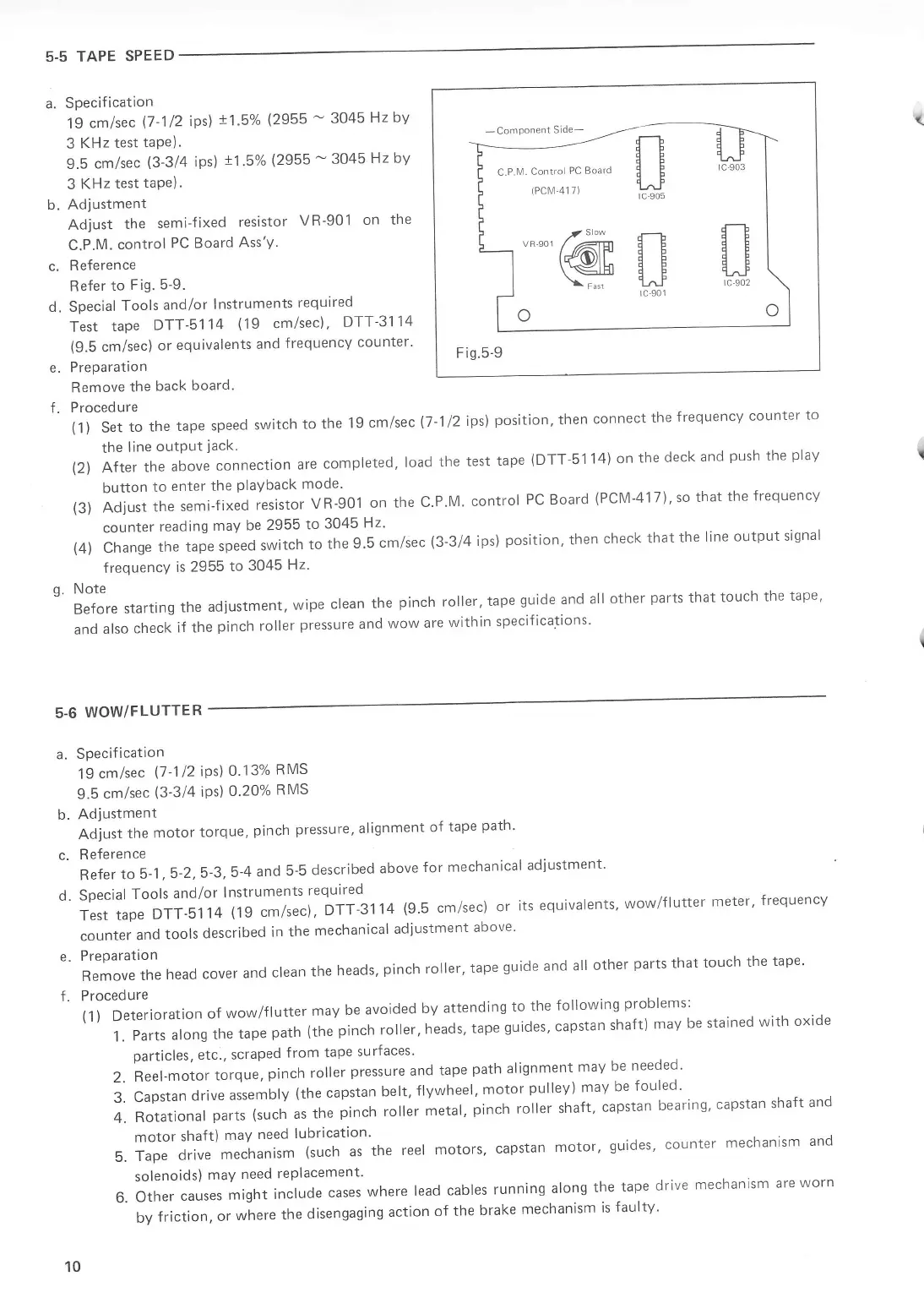

b. Adjustment

Adjust

the

semi-fixed

resistor

VR-901

on

the

C.P.M.

control

PC Board

Ass'Y.

c.

Reference

Refer

to

Fig.

5-9.

d. Special

Tools

and/or

lnstruments

required

Test

tape

DTT-5114

(19

cm/sec)

,

DTT

3114

(9.5

cm/sec)

or

equivalents

and

frequency

counter'

e.

Preparation

Remove

the

back

board'

f.

Procedure

(1)

Set

to

the

tape

speed

switch

to

the

19

cm/sec

the

line

outPut

jack.

-Component

Slde-

C.P.lvl.

Control

PC

Board

(PCN1

41

7)

$-l

q_J

##

F

ig.5-9

test

tape

(DTT

51

14) on

the

deck

and

push

the

play

control

PC Board

(PCM-417),

so

that

the

frequency

-

3045

Hz

bY

-

3045

Hz bY

(-

(7-1

12

ips\

position.

then

connect

the

frequency

counter

to

(2)

After

the

above

connection

are

completed,

load

the

button

to

enter

the

PlaYback

mode'

(3)

Adjust

the

semi-fixed

resistor

VR-901

on

the

C'P'M'

counter

reading

may

be 2955

to

3045

Hz'

position,

then

check

that

the

line

output

signal

(4)

Change

the

tape

speed

switch

to

the

9'5

cm/sec

(3

3/4

ips)

frequencY

is

2955

to

3045

Hz'

q'

Note

r:..^.-^^+ ,^,i^a nraen r

de

and

all

other

parts

that

touch

the

tape,

Before

starting

the

adjustment,

wipe

clean

the

pinch roller'

tape

gul

andalsocheckifthepinchrollerpressureandwowarewithinspecifications'

5-6

WOW/FLUTTER

L

t

L

a.

Specification

19

cm/sec

(7

l12iPs]r

0'13%

RMS

9.5

cm/sec

(3-3/4

iPs)

0.20%

RMS

b.

Adjustment

Adiust

the

motor

torque,

pinch

pressure'

alignment

of

tape

path'

c.

Reference

RefertoS-1,5.2,5.3,5-4and5-5describedaboveformechanicaladiUstment.

d.

Special

Tools

and/or

lnstruments

required

TesttapeDTT-s114(1gcm/sec),DTT-3114(9.5cm/sec)oritsequivalents,wow/fluttermeter,frequency

counter

and

tools

described

in the

mechanical

adjustment

above'

e.

Preparation

Remove

the

head

cover

and

clean

the

heads,

pinch

roller,

tape

guide

and

all

other

parts

that

touch

the

tape'

f.

Procedure

(1)

Deterioration

of

wow/flutter

may

be

avoided

by

attending

to

the

following

problems:

l.Partsalongthetapepath(thepinchroller,heads,tapeguides'capstanshaft)mavbestainedwithoxide

particles,

etc., scraped

from

tape

surfaces'

2.Reel-motortorque.pinchrolIerpressureandtapepathalignmentmaybeneeded.

3.

capstan

drive

assembly

(the

capstan

belt,

flywheel.

motor

pulley) may

be

fouled'

4.

Rotational

parts

(such

as

the

pinch

roller

metal,

pinch roller

shaft,

capstan

bearing'

capstan

shaft

and

motor

shaft)

may

need

lubrication'

5.

Tape

drive

mechanism

(such

as

the

reel

motors,

capstan

motor'

guides'

counter

mechanism

and

solenoids)

maY

need

rePlacement'

6.

other

causes

might

include

cases

where

lead

cables

running

along

the

tape

drive

mechanism

are

worn

by

friction,

or

where

the

disengaging

action

of

the

brake

mechanism

is

faulty'

10

L

Loading...

Loading...