(Bulletin R55/7A) continued)

2.

3.

4.

5.

6.

7.

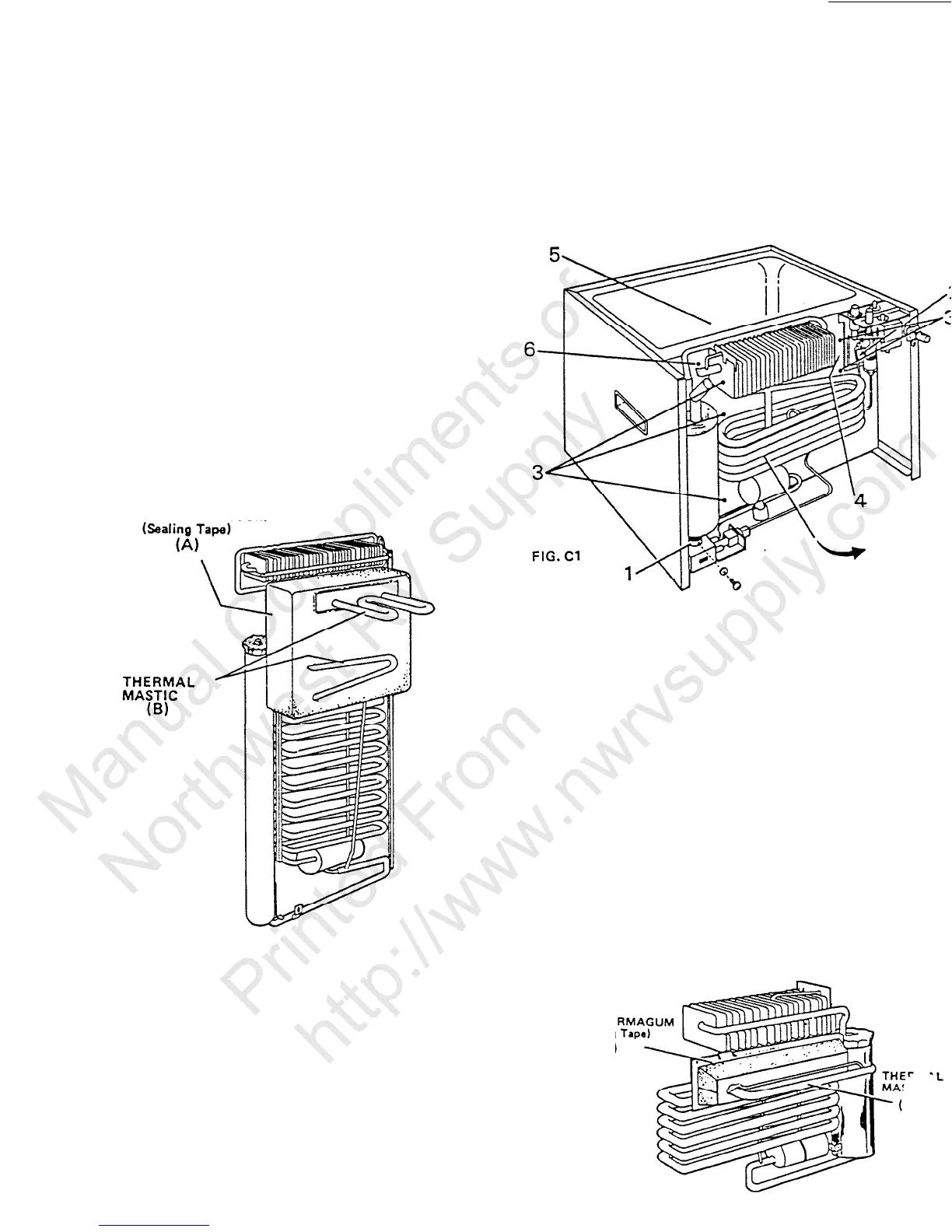

Apply sealing permagum (sealing tape) on

mounting plate (A; FIG.

B5).

Apply thermal mastic on the evaporator coil

(B; FIG.

B5).

Tighten screws securely to obtain proper

contact between the evaporator coil and

evaporator flange;

otherwise improper cabinet

performance may result.

Install the heater element completely back

into pocket and plug in.

Reinstall capillary tube into proper position.

a.

RMl00,

RM2600

&

RM2800 will clamp to

cooling flange. (FIG. B4)

b.

RM760, RM761

&

RM763 will extend into

retainer tube approximately 31” (FIG .

Bl)

C.

RM1300, RM1301

`

RM1303 will extend

into retainer tube approximately 36”

(FIG.

Bl)

d.

RM3600

&

RM3800 have internal thermostat

with capillary tube clamped to cooling

flange (FIG. B4)

Reconnect the burner assembly to chimney.

SEALING PERMAGUM

FIG.

B5

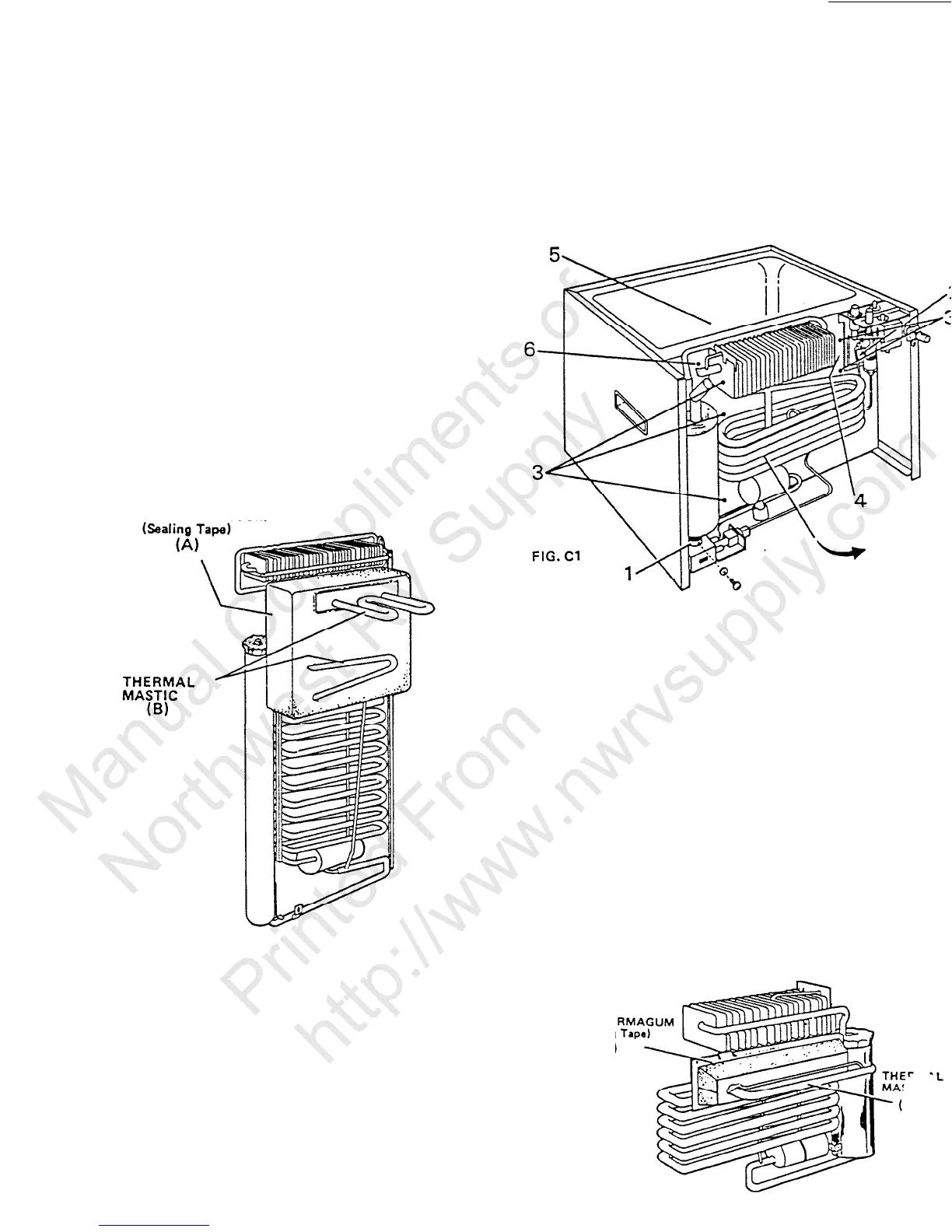

C. Category

#3

RC150

RC160

REMOVAL OF COOLING UNIT:

1. Remove screw and disconnect burner

chimney (FIG. Cl).

2. Disconnect heater wires from terminal

(FIG. Cl).

from

block

a.

Remove heaters from boiler case (FIG. Cl).

D-9-6

3.

4.

5.

6.

7.

Remove screws holding unit from rear (FIG.

Cl).

Disconnect green grounding wire (FIG. Cl).

Pull out on cooling flange to remove

fr

evaporator coil (FIG. Cl).

Pull thermostat capillary tube out gently and

move so that cooling unit will clear (FIG. Cl).

Remove cooling unit by hinging out on right

side (FIG. Cl).

INSTALL REPLACEMENT COOLING UNIT:

1.

2.

3.

4.

5.

6.

7.

Trim the Styrofoam portion of the cooling

unit if it does not go freely into the

refrigerator.

Apply sealing permagum (sealing tape) on

window insulation (A; FIG. C2).

Apply thermal mastic on the evaporator coil

(B; FIG. C2).

Tighten screws securely to obtain proper

seal; otherwise improper cabinet performance

may result.

Install the heat elements completely back

into the pocket and attach to terminal block

(FIG. Cl).

Reconnect burner assembly to chimney (FIG.

Cl).

Reinstall capillary tube into proper position

(FIG. Cl).

SEALING PE

(Sealing

(A)

FIG. C2

Loading...

Loading...