26

8.7 Cooling Unit

The cooling unit is a self-contained, hermetically sealed

set of coils where the refrigeration process takes place.

The chemicals involved in the cooling process include

hydrogen, ammonia, water and a rust inhibiting agent.

There are no repairs recommended on the cooling unit.

If it is defective, replace with a new cooling unit. To check

the cooling unit, rst verify the AC heating element is

good, proper ohms at room temperature, proper venting

and unit is level. Then place approximately one gallon of

water inside the refrigerator and place a thermometer in

one of the containers of water. Next, unplug the therm-

istor from the lower control board. This will by-pass the

thermostat control and operate for at least 12 hours. Then

check the temperature on the thermometer. It should be

at 43 degrees or lower depending on test conditions. If so,

the cooling unit is good. If the temperature of the water is

above 43 degrees, replace the cooling unit. The outside

temperature will affect the cooling capacity of the unit.

There is that rare occasion when the cooling unit will work

OK for the rst 12 hours and then start to warm up. If the

customers complaint is “works OK for 2 to 5 days and

then warms up” the unit may have an internal problem. To

test this it would be necessary to operate the cooling unit

for up to 24 to 48 hours in the test mode.

8.8 Food Storage

Proper refrigeration requires free air circulation within the

food storage compartment. Restricted air circulation within

this compartment will cause higher cabinet temperatures.

To remedy this situation, simply rearrange your foodstuffs.

It is also essential that the shelves are not covered with

paper or large storage containers. Always remember to

allow for proper air circulation. Odorous or highly avored

foods should always be stored in covered dishes, plastic

bags or wrapped in foil or waxed paper to prevent food

odors. Vegetables, lettuce, etc., should be covered to re-

tain their crispness.

NEVER PUT HOT FOOD INTO THE REFRIG-

ERATOR.

To reduce frost formation in and on the freezing compart-

ment, cover stored liquids and moist foods and do not

leave the door open longer than necessary. When the

refrigerator is heavily loaded, it takes a longer time for

refrigerator temperatures to lower, also increasing the ice

making time. A very heavy load may also cause defrost-

ing. Defrosting every 7 to 21 days would be normal, de-

pending on the humidity level.

8.9 High Humidity

High humidity may cause a small amount of condensation

to form on the frame of the refrigerator. In some cases it

can develop to such a degree that it will run off the frame.

As the humidity is reduced, the sweating will decrease.

High humidity can also be a factor in rapid formation of

frost.

9.1 Internal Wiring

Check all wires and the connectors to ensure a proper

and tight connection. Also verify the refrigerator is wired

per the wiring diagram for the model you are working on.

(See applicable wiring diagrams for your model refrigera-

tor). A loose connection can create erratic operation. Al-

ways check the wires at the DC terminal block, two wires

in and two wires out.

SECTION 9 WIRING

9.2 External Wiring

120 Volts AC Connection: The refrigerator is equipped

with a three prong (grounded) plug for protection against

shock hazards and should be plugged directly into a prop-

erly grounded three prong receptacle. DO NOT cut or re-

move the grounding prong from this plug.

12 Volt Connection : The connection is made to the ter-

minal block marked 12 volts DC. The control system is

connected to a battery/converter circuit and could draw

about 3 amps at 12 volts DC. The refrigerator must be

connected to the battery circuit with two wires of adequate

capacity to avoid voltage drop. Proper polarity is crucial

for refrigerator operation. Don’t use the chassis for the

ground circuit. No other electrical equipment or light-

ing should be connected to refrigerator circuit. A loose

connection will create erratic operation.

On three way units the DC heater will draw up to 18

AMPS and size of wires should follow installation in-

structions for the model unit you are working on.

9.3 Wiring Schematics

To view typical wiring schematics look in the Lower Circuit

board testing section 5, pages 14, 15 and 16. All units

should have a specic schematic on the rear of that unit.

To acquire the proper one always have the product num-

ber when you call or e-mail.

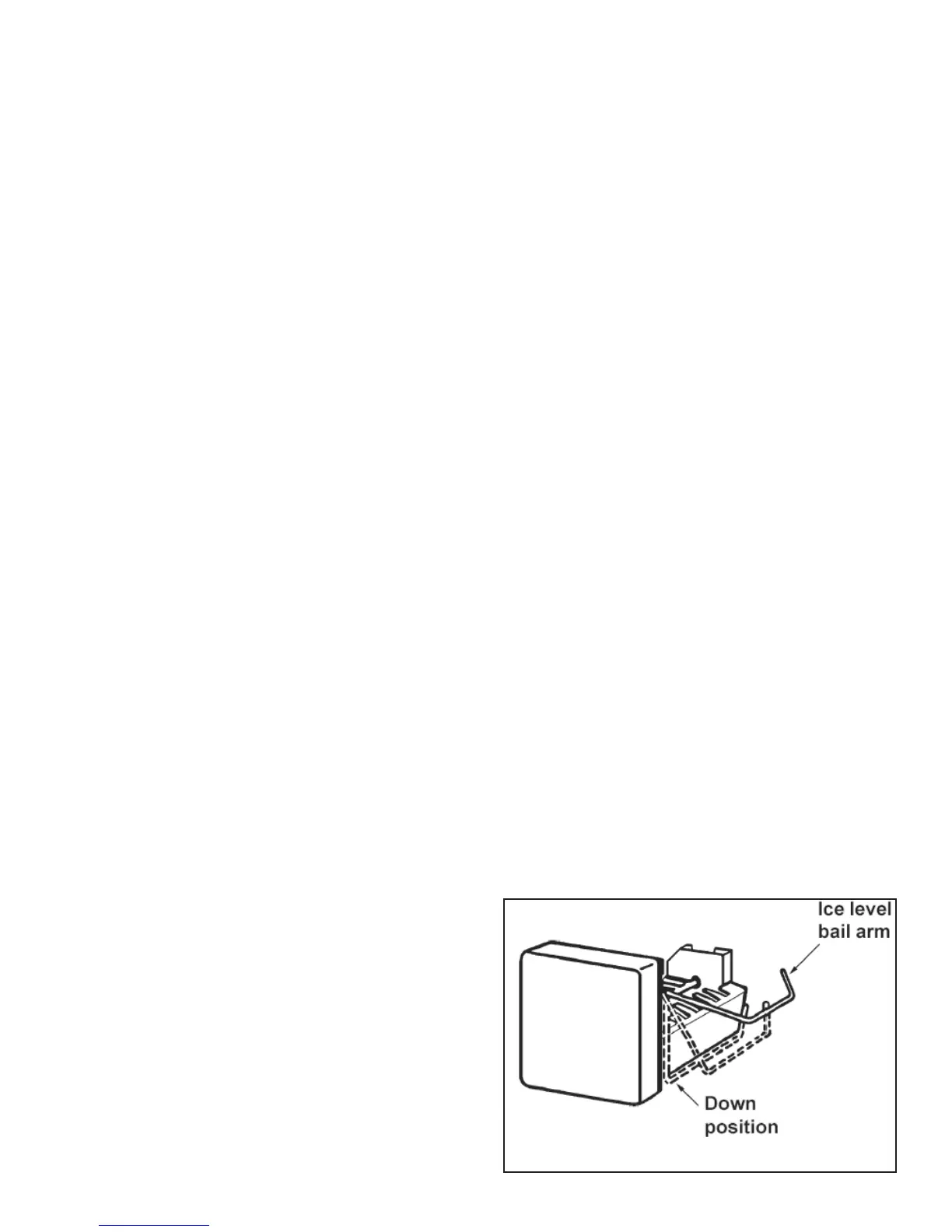

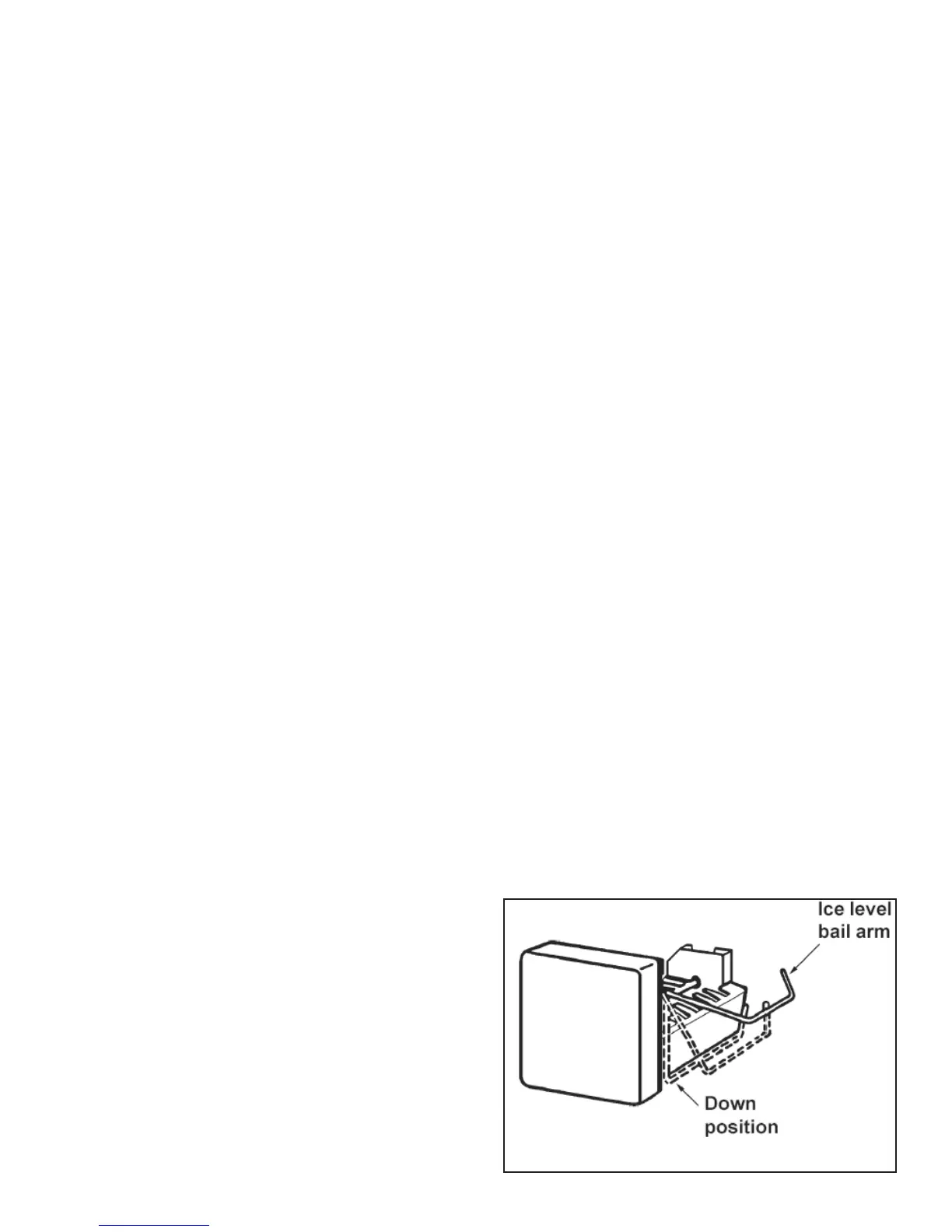

SECTION 10 ICE MAKER

10.1 Operation

The refrigerator must be allowed to precool properly be-

fore starting the ice maker. The refrigerator has to be con-

nected to 120 volts AC before the ice maker can operate.

The water line manual shutoff valve (not part of Dometic

unit) must be open. To start making ice, move the ice level

bail arm to DOWN position.

Loading...

Loading...