27

When the ice maker thermostat senses the preset tem-

perature for ejection of the ice cubes, the ngers will start

to rotate, dumping any ice cubes and lling the mold with

water. When the storage container is full of ice, the ice

level bail arm cannot return to the DOWN position. This

will stop further production of ice until the container is

emptied and the bail arm is returned to the down position.

The absorption system will keep the compartment at the

proper temperature for storage of ice. Ice making is ac-

celerated if the thermostat is set to the coldest position. It

is a good idea to do this a few hours before you anticipate

a need for ice. The rst few cycles may have small cubes

due to air trapped in the water lines. The rst container of

ice cubes should be dumped if the water system has been

winterized or not used for several weeks.

Note: if the ice maker was cleaned and drained, no ice

cubes will be dumped into the storage container during

the rst few cycles.

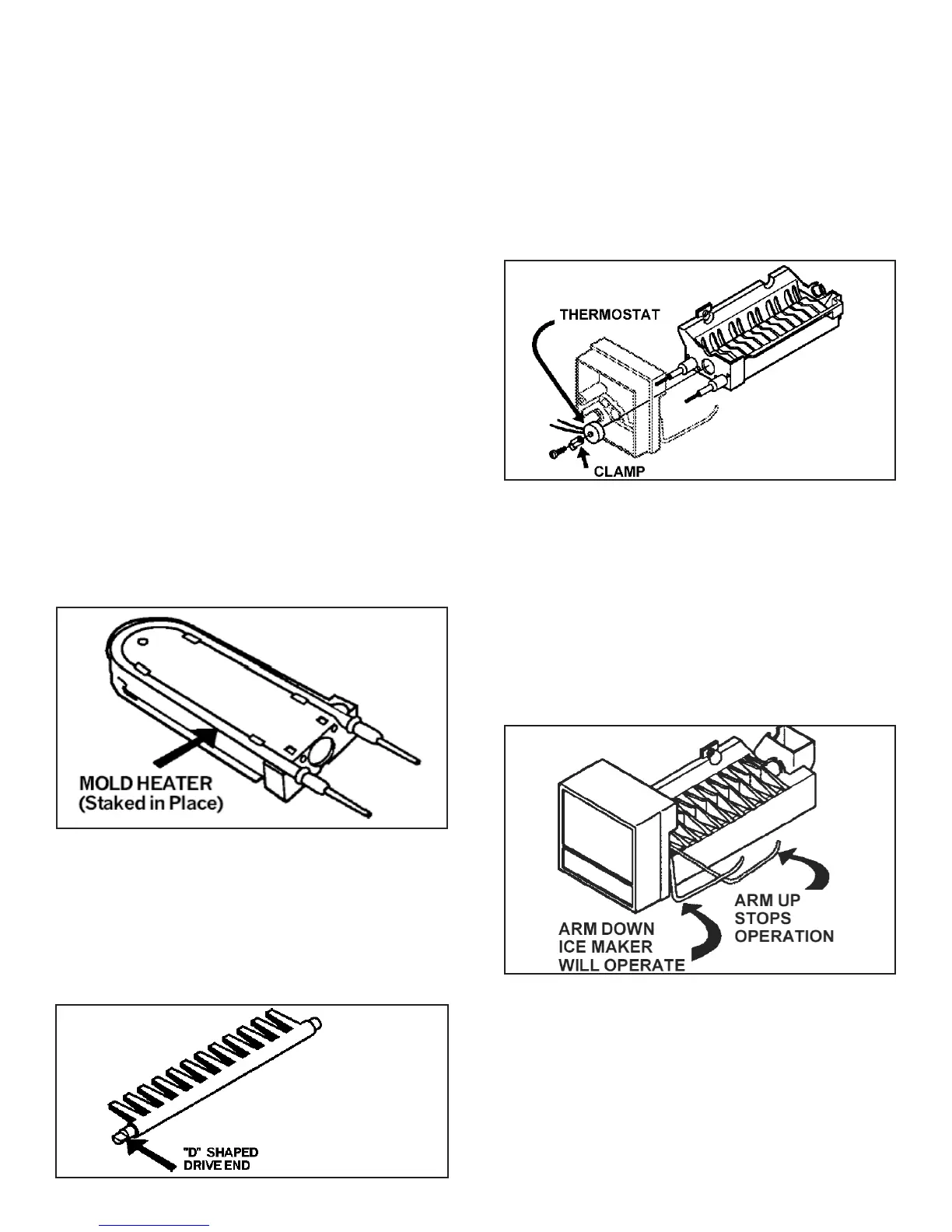

10.2 Mold Heater

The mold heater uses 165 watts to thaw the ice free from

the mold. It is wired in series with the thermostat which

also acts as a safety device. With power to the appli-

ance off, check for resistance between the two leads to

the heater element. You should obtain a reading of ap-

proximately 80 ohms +/- 10%. If the heater is found to be

defective, the manufacturer recommends replacement of

the entire ice making unit for proper operation.

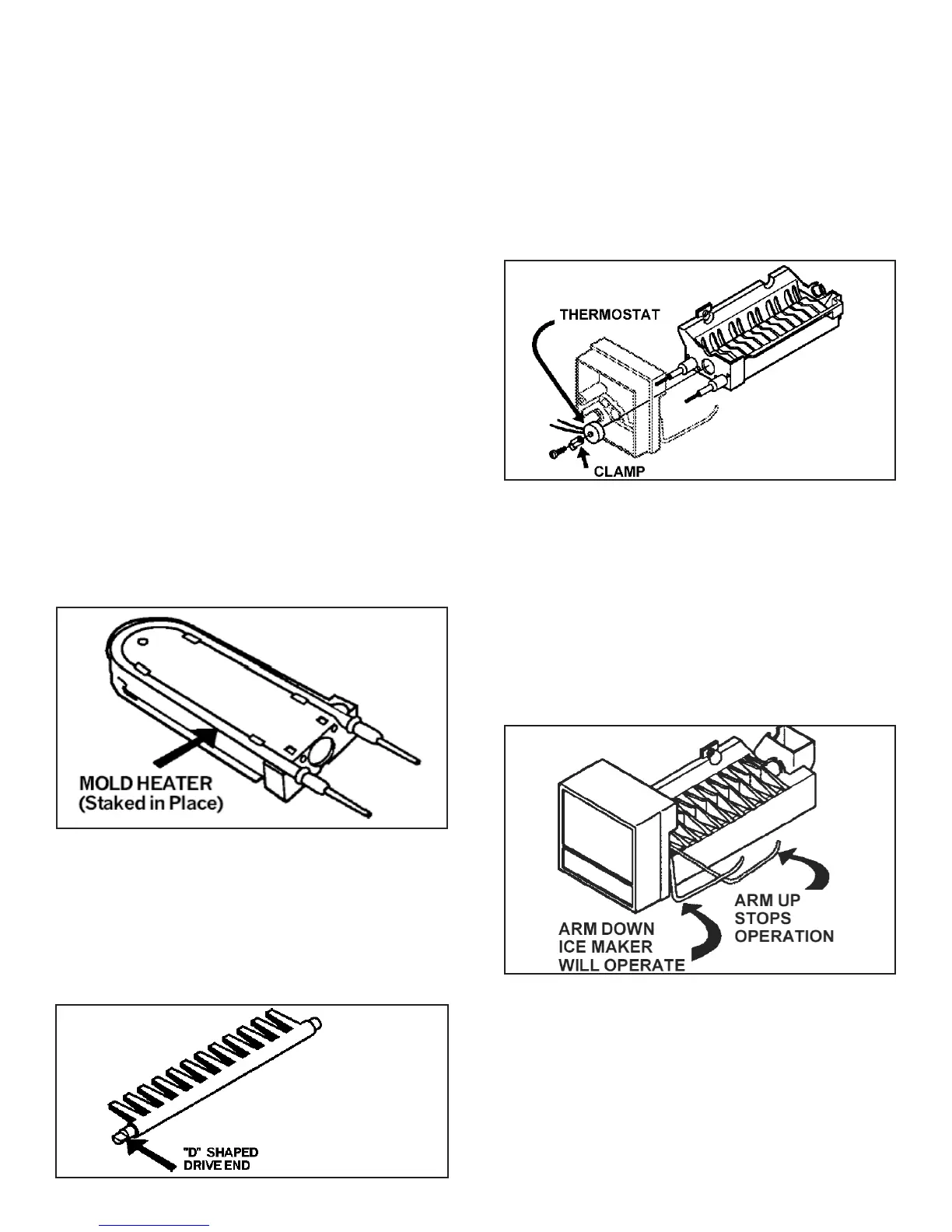

10.3 Ice Ejector

The ice ejector blades sweep the ice from the mold cavi-

ties during the ejection cycle. The drive end of the ejector

is “D” shaped for positive coupling. The bearings at both

ends are lubricated with silicone grease. If the ejector

blades are frozen into the ice, defrost the ice maker and

manually cycle the ice making unit, making sure the ejec-

tor stops at the right location.

10.4 Mold Thermostat

This is a single-pole, single-throw, bimetal switch. It starts

an ejection cycle by closing at 15º F ± 5º. The reset tem-

perature is 50º F ± 5º. The thermostat is in series with the

mold heater and acts as a safety against overheating in

case of a mechanical failure. If the thermostat is defec-

tive, replace it. The mold thermostat starts the ice ejection

cycle. The freezer must be down to proper temperature

for the mold thermostat to start the cycle. The cycle can

be started by turning the large gear clock wise 1/8 to 1/4

of a turn.

10.5 Shut Off Arm

The shutoff arm is cam driven. It operates a switch to con-

trol the quantity of ice produced. During the ejection cycle

the arm is raised and lowered during each of the two revo-

lutions of the timing cam. If the shutoff arm comes to rest

on top of the ice in the storage bin during either revolution,

the switch will remain open and stop the ice maker at the

end of that revolution. The arm has a manual shutoff built

into the linkage; by raising the arm as high as possible, it

will lock in that position until forced down. If the arm and

switch do not operate properly, check for damage and re-

pair or replace parts as necessary.

10.6 Mold Switches

The three switches are single-pole, double-throw style.

They are identical and interchangeable. The holding

switch assures completion of a revolution once a cycle

has started. The water valve switch opens the water

valve during the ll stage of the cycle. NOTE: This is the

only adjustable component of the ice maker. If you use a

double throw switch, DO NOT use the N.O. terminal. The

shutoff switch stops the ice maker’s operation when the

storage bin is full.

Loading...

Loading...