26

APPENDIX

Place for the control unit

installation

Place for the external hydraulic

power station installation

Place for the control unit

installation

Place f

or the external hydraulic

power station installation

View 1

View 1

View 1

View 2

View 2

View 2

Pipe Ø80 mm for cabling from hydraulic power

station to control unit or for laying hoses from

hydraulic cylinders to external hydraulic power

station. Bend with an angle 90 °. Bending radius

is more than 160 mm

∅

Pipe 80 mm

Pipe mm

∅

Fitting 16 mm, step 300 mm

0×100×

Corner mm

×75×

Corner mm

∅

Fitting 16 mm

Concrete

Concrete

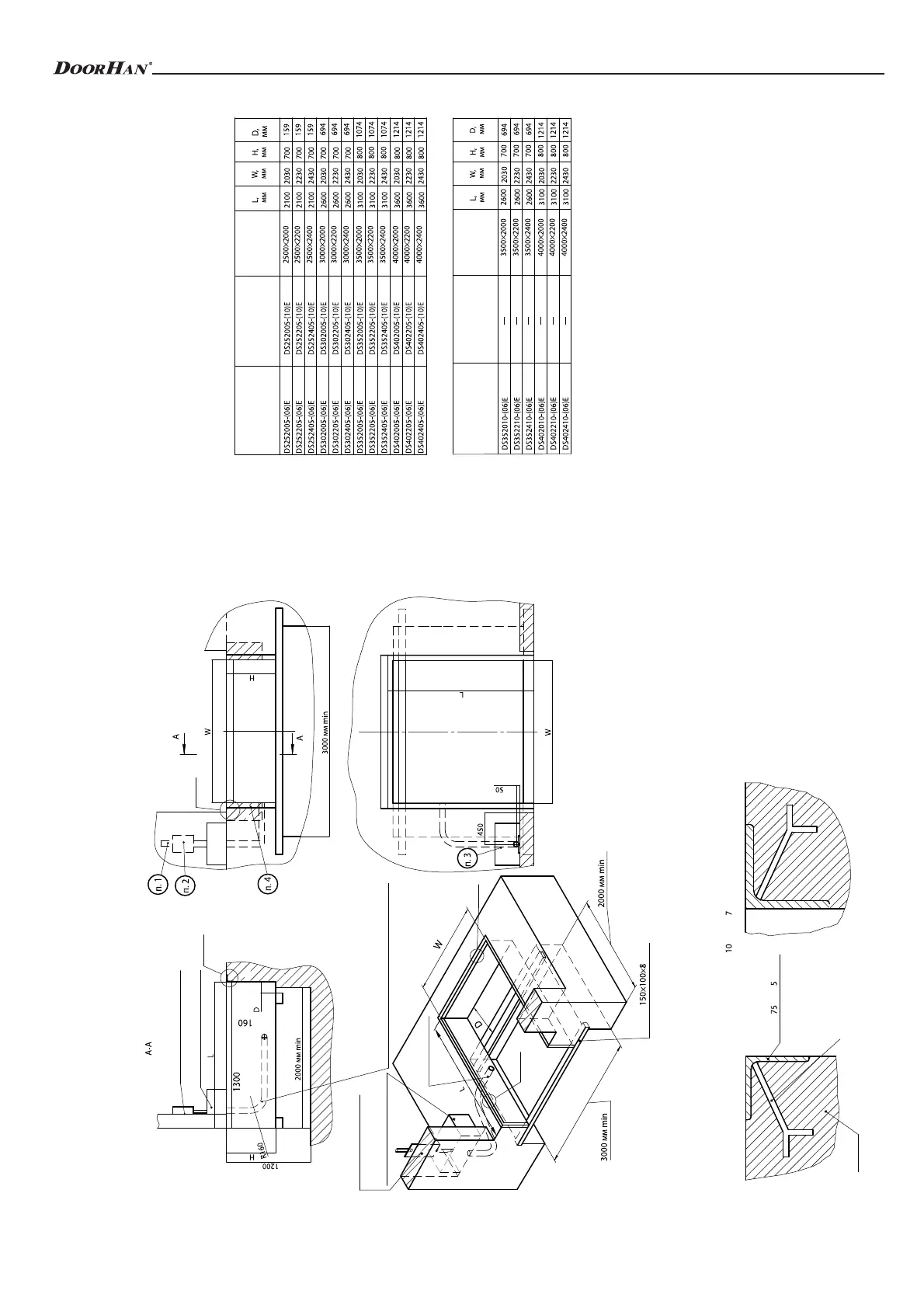

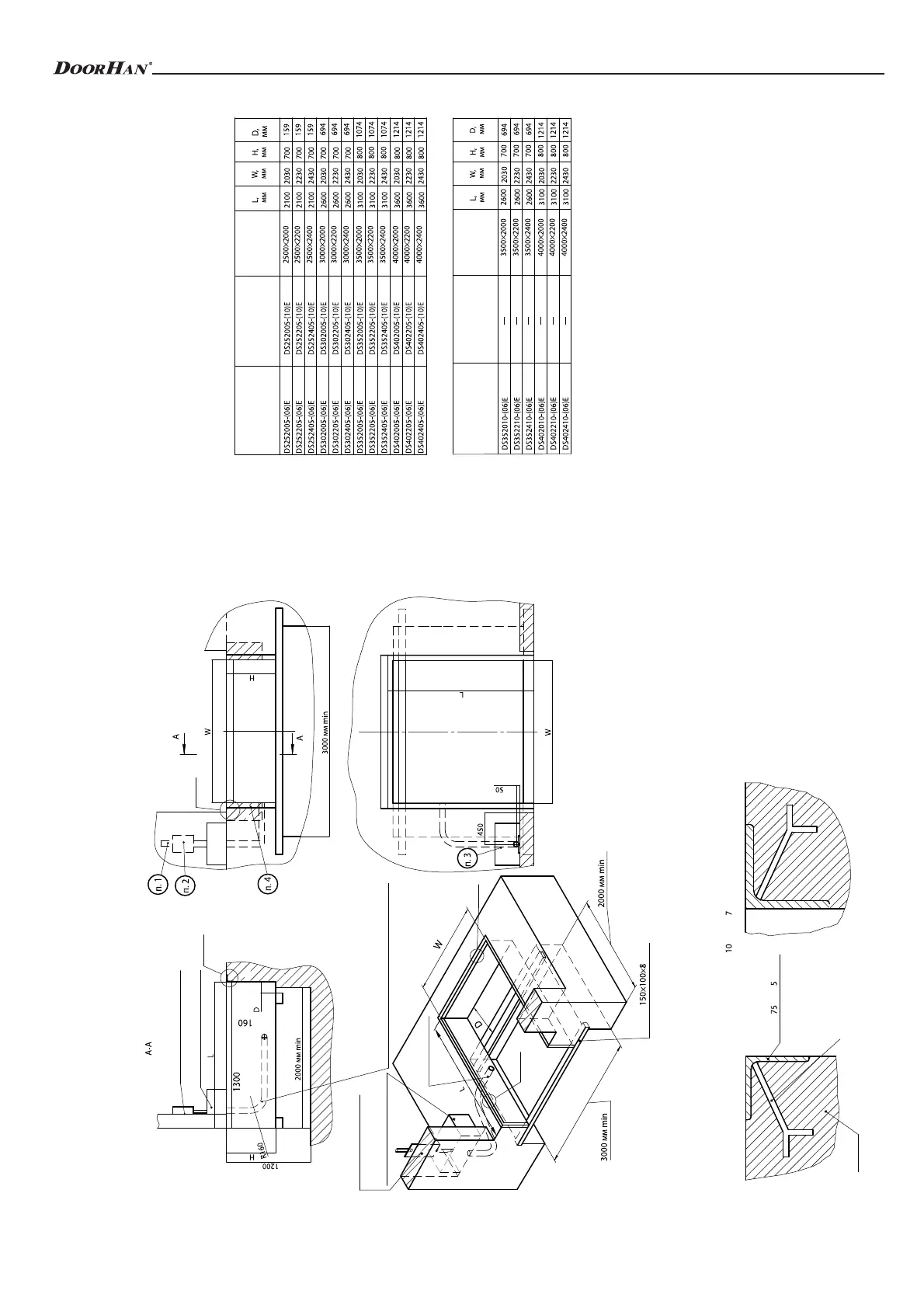

Size of the dock leveler pit (the lip 500 mm)

Size of the dock leveler pit (the lip 1000 mm)

Article of the dock

leveler series DS

with load

capacity 6 tones

Article of the dock

leveler series DS

with load

capacity 10 tones

Size of the dock

leveler

(length* x width),

mm x mm

Article of the dock

leveler series DS

with load

capacity 6 tones

Article of the dock

leveler series DS

with load

capacity 10 tones

Size of the dock

leveler

(length* x width),

mm x mm

The diagram for the pit preparation and installation of

embedded parts for the dock leveler with integrated telescopic

lip 500 mm, 2000 mm wide, 2500 mm long* and 700 mm high,

when used with vehicle with built-in lift

* Dock leveler length – from the edge of opened lip to the dock leveler cover

rotation axis.

1. 400 V (3 phases+neutral+ground) connect to the place of the control unit instal-

lation for the dock leveler.

2. It is required to provide surface of 200x300 mm for the place of the control unit

installation for the dock leveler.

3. In case of ordering the dock leveler with external hydraulic power station, it is

required to provide surface of 350x600 mm.

4. It is required to provide surface for rubber bumpers installation. See Section

“Optional Equipment”.

Diagram for the pit preparation and installation of embedded parts for the dock leveler with integrated

telescopic lip when used with vehicle with built-in lift

Loading...

Loading...