70

PERIODICAL INSPECTI ON AND MAINT ENANCE.

7/72

Inspection every 2000 hours operation

(1) Flushing the cooling system and checking the cooling

system parts

As this maintenance requires specialized knowledge and skill, consult

your Portable Power dealer. Rust and water scale will accumulate in the

cooling system through many hours of operation. This lowers the

engine cooling effect.

(2) Checking and replacing fuel hoses and cooling water hoses

As this maintenance requires specialized knowledge and skill, consult

your Portable Power dealer . Regularly check the rubber hoses of the

fuel system and cooling water system. If cracked or degraded, replace

them with new one. Replace the rubber hoses at least every 2 years.

(3) Lapping the intake and exhaust valves

As this maintenance requires specialized knowledge and skill, consult

your Portable Power dealer . The adjustment is necessary to maintain

proper contact of the valves and seats.

(4) Checking and adjusting the fuel injection timing

As this maintenance requires specialized knowledge and skill, consult

your Portable Power dealer .

(5) Checking and adjusting the EP A emission related parts.

The inspection and servicing require specialized knowledge and

techniques. Consult your Portable Power dealer or distributor.

EP A allows to apply maintenance schedule for emission related parts

as follows:

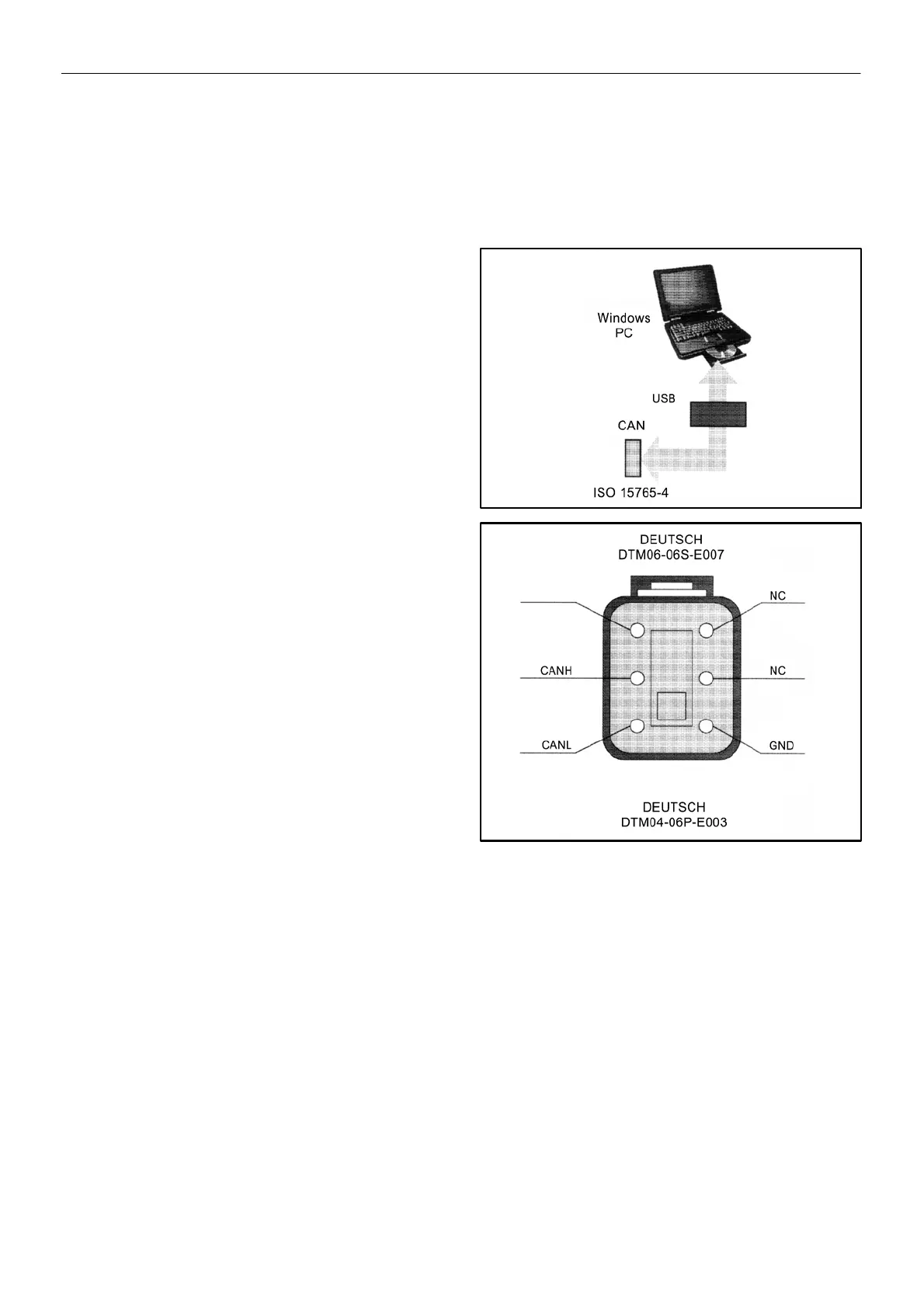

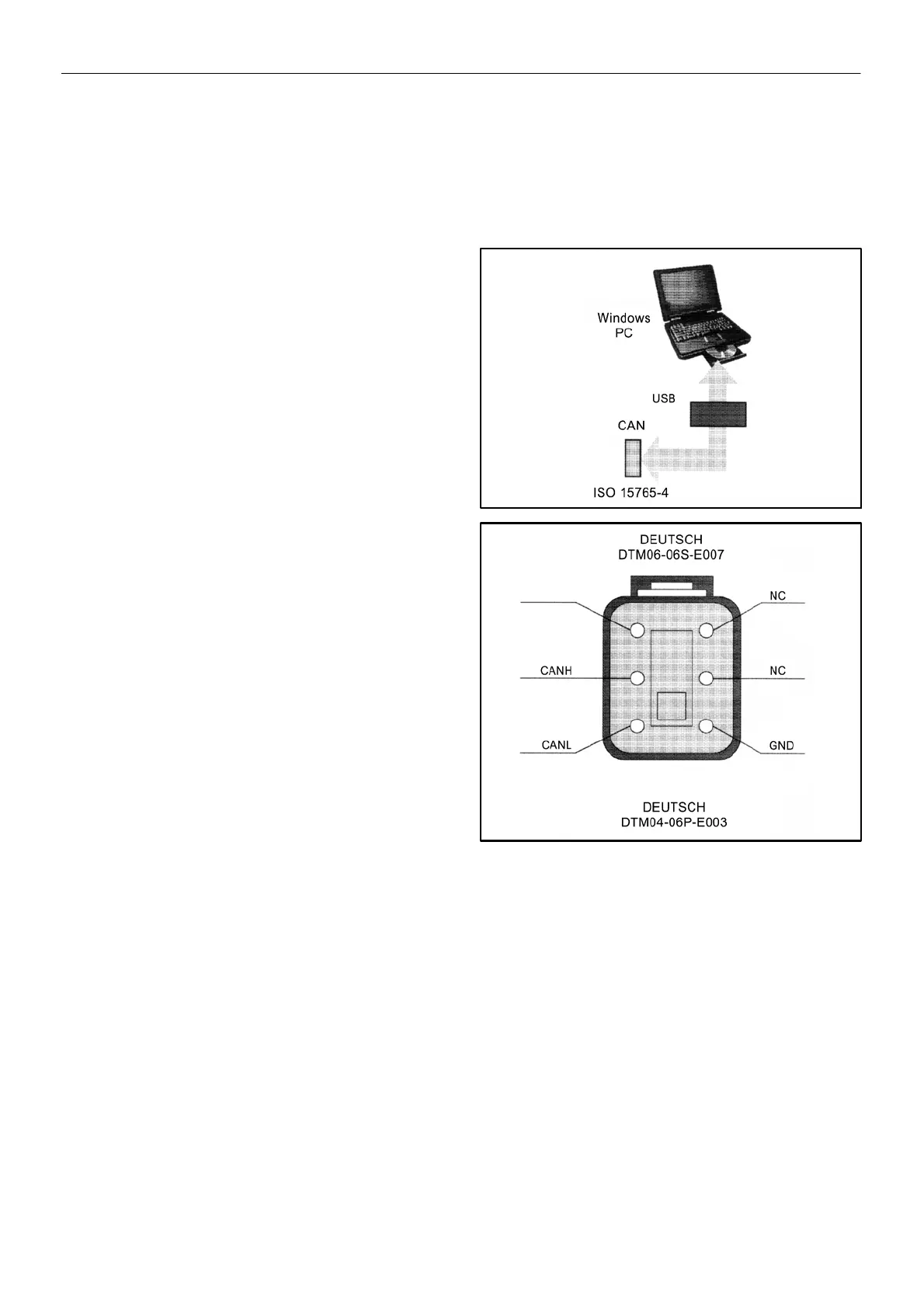

Diagnosis Tool

A connector is provided at an end of the harness of the driven machine

so that the diagnosis tool can be loaded with data from the E--ECU.

When the fuel injection pump is replaced, data in the E--ECU must also

be replaced for accomodating the new pump. When the EECU is

replaced, the fuel injection data in the existing unit must be migrated to

the new unit. The diagnosis tool can be used for the data replacement

or migration. Contact your local Portable Power dealer for replacement

of the fuel injection pump or E--ECU.

Diagnosis Tool

(Y anmar genuine)

Communication

adaptor

Battery 12V

Mating connector (Tool side)

Loading...

Loading...