Disassembly and assembly of major components

- 100 -

●

Pushing the piston down, rotate the crank-

shaft about 180

°

and fit the bearing cap to

the connecting rod.

●

After engaging 2 - 3 threads of bolts primar-

ily rind then tighten them.

<Connecting rod bolt tightening order>

(1) First step : Engage 2 - 3 threads by hands.

(2)

Second step : Tighten to about 7 kg.m with wrench.

(3)

Third step : By means of torque wrench tighten to 10 kg.m.

(4)

Fourth step : Finally assemble by means of rotation angle method 90°+10°.

However, according to above tightening order, tighten them step by step.

* Standard length of bolt and use limit:

(from head seat to bolt tip)

●

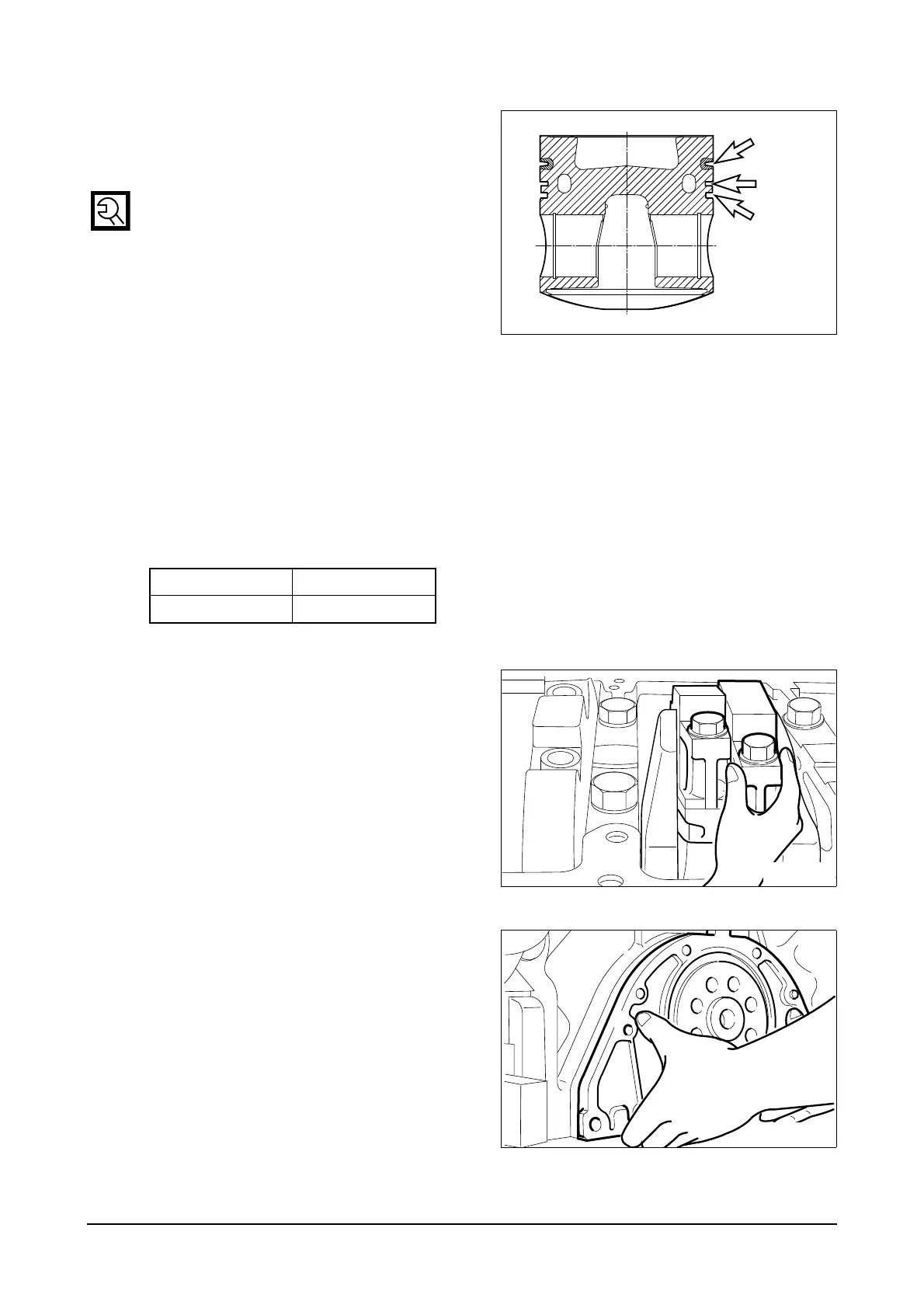

By moving the connecting rod bearing cap

by hands, make sure if there is any play in

left and right.

●

With same ways as above, assemble in

each cylinder rotating the crankshaft.

6.3.15. Front oil seal holder

●

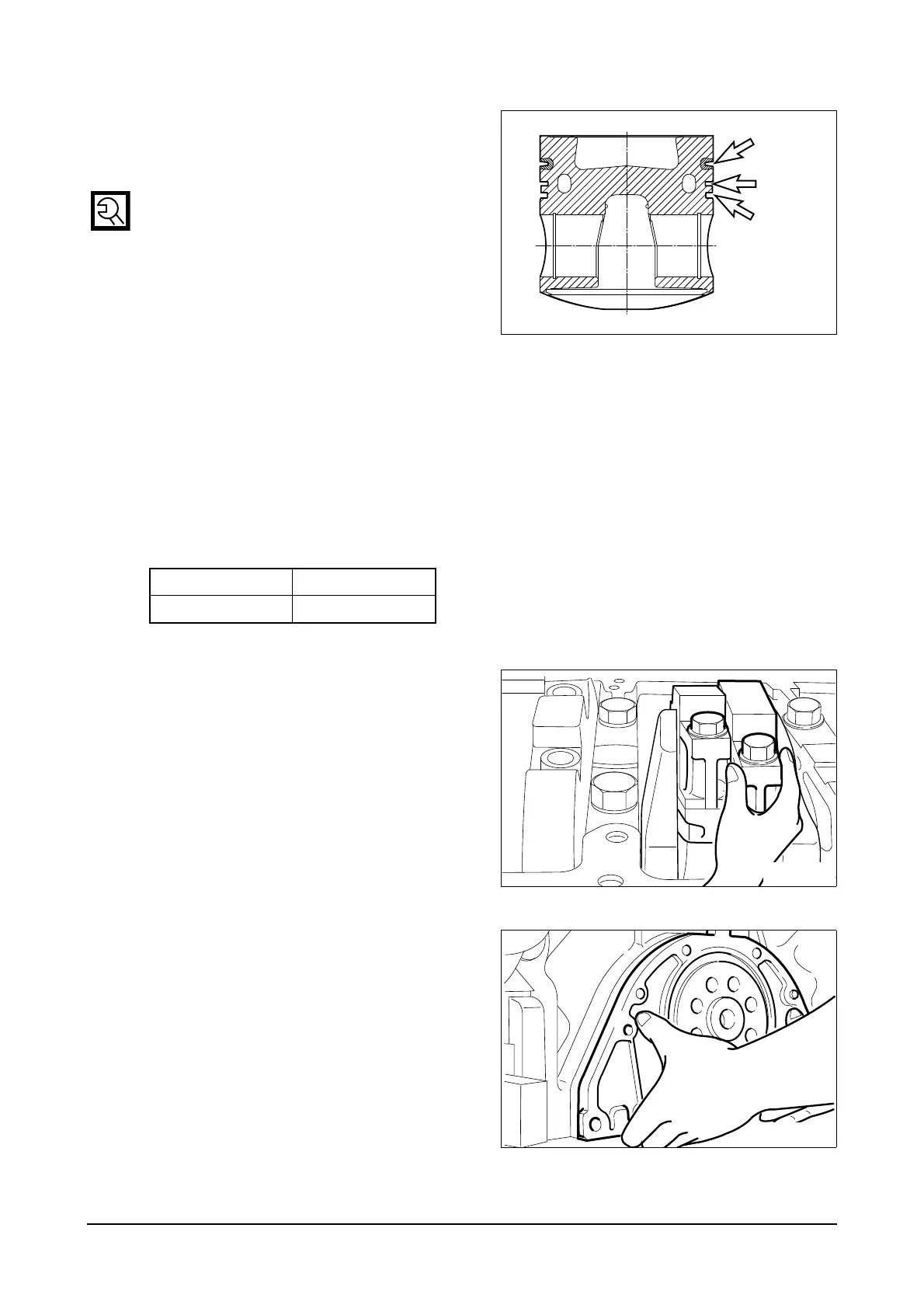

After placing the oil seal in the oil holder

hole properly, press it in with a mandrel. (Be

careful for oil seal not be damaged.)

●

Attach the gasket at oil seal holder.

●

Align the dowel pin with the oil seal holder

dowel hole and assemble them by tapping

lightly the dowel pin part with an urethane

hammer.

EA6M2006

Top ring

2nd ring

Oil ring

Standard length Use limit

67.5

-

0.3

mm 69 mm

Loading...

Loading...